Method for liquefying straws by ionic liquid

An ionic liquid and straw technology, applied in the direction of adhesive type, lignocellulosic material adhesive, etc., can solve the problems of low residue rate, mild liquefaction conditions and can not have both, achieve rich sources, reduce liquefaction residue rate, equipment less corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

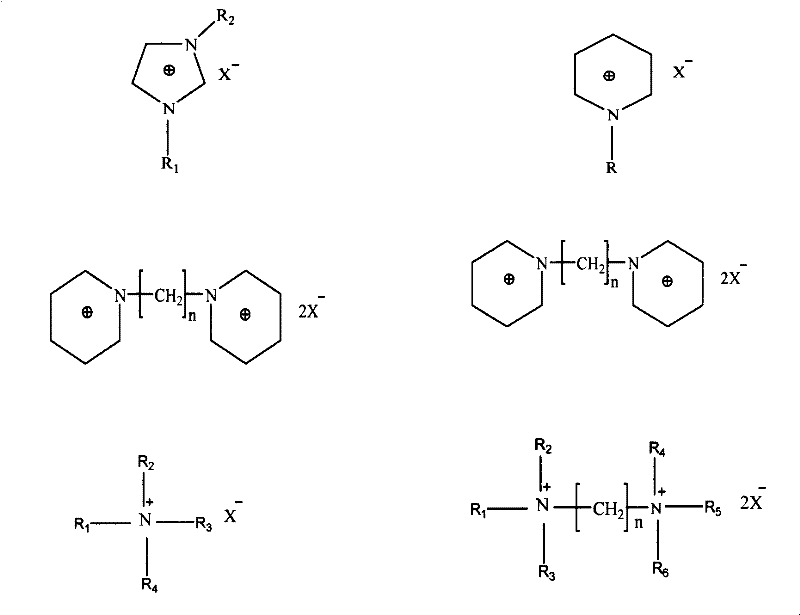

Method used

Image

Examples

Embodiment 1

[0020] The ionic liquid used is 1-butyl-3-methylimidazolium chloride ([bmin]Cl)

[0021] The implementation method is: add 10g[bmin]Cl and 0.5g straw to a three-necked flask, 2 Stir in an oil bath and heat to 100°C, react for a period of time, stop the reaction when the color of the solution changes from colorless to purple-brown, and filter the mixture at the reaction temperature or slightly lower temperature to obtain the liquefied product. The residue was dried at 105°C to constant weight, and the liquefaction yield was 95%.

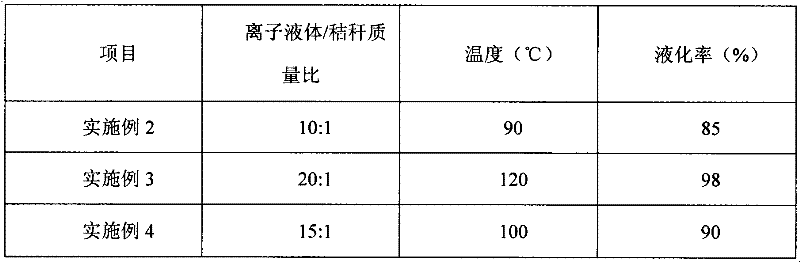

Embodiment 2~4

[0023] The implementation method is as follows: follow the same experimental procedure as in Example 1, but use different ionic liquid / straw mass ratios, and the results are shown in Table 1.

[0024] Table 1 The results of liquefaction of straw with different qualities in ionic liquid

[0025]

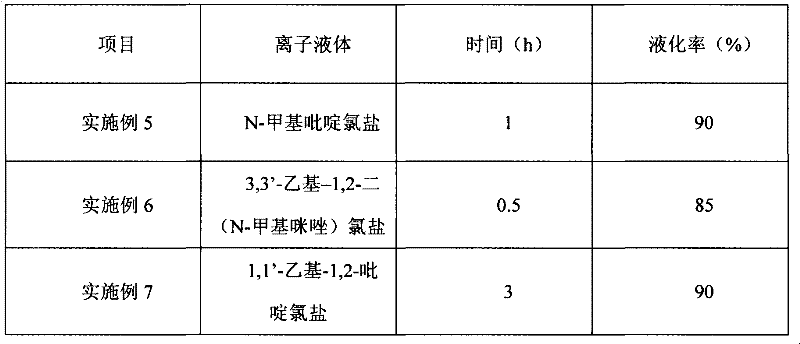

Embodiment 5~7

[0027] The implementation method is: according to the same experimental procedure as in Example 1, but using different ionic liquids, the results are shown in Table 2.

[0028] Table 2 Liquefaction of straw in different ionic liquids

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com