Process for preparing granular biomass fuel by using pig manure and prepared product

A granular biomass, biomass technology, applied in the direction of biofuel, waste fuel, fuel, etc., to achieve good deodorization effect, good flotation effect, and reduce the effect of ignition point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

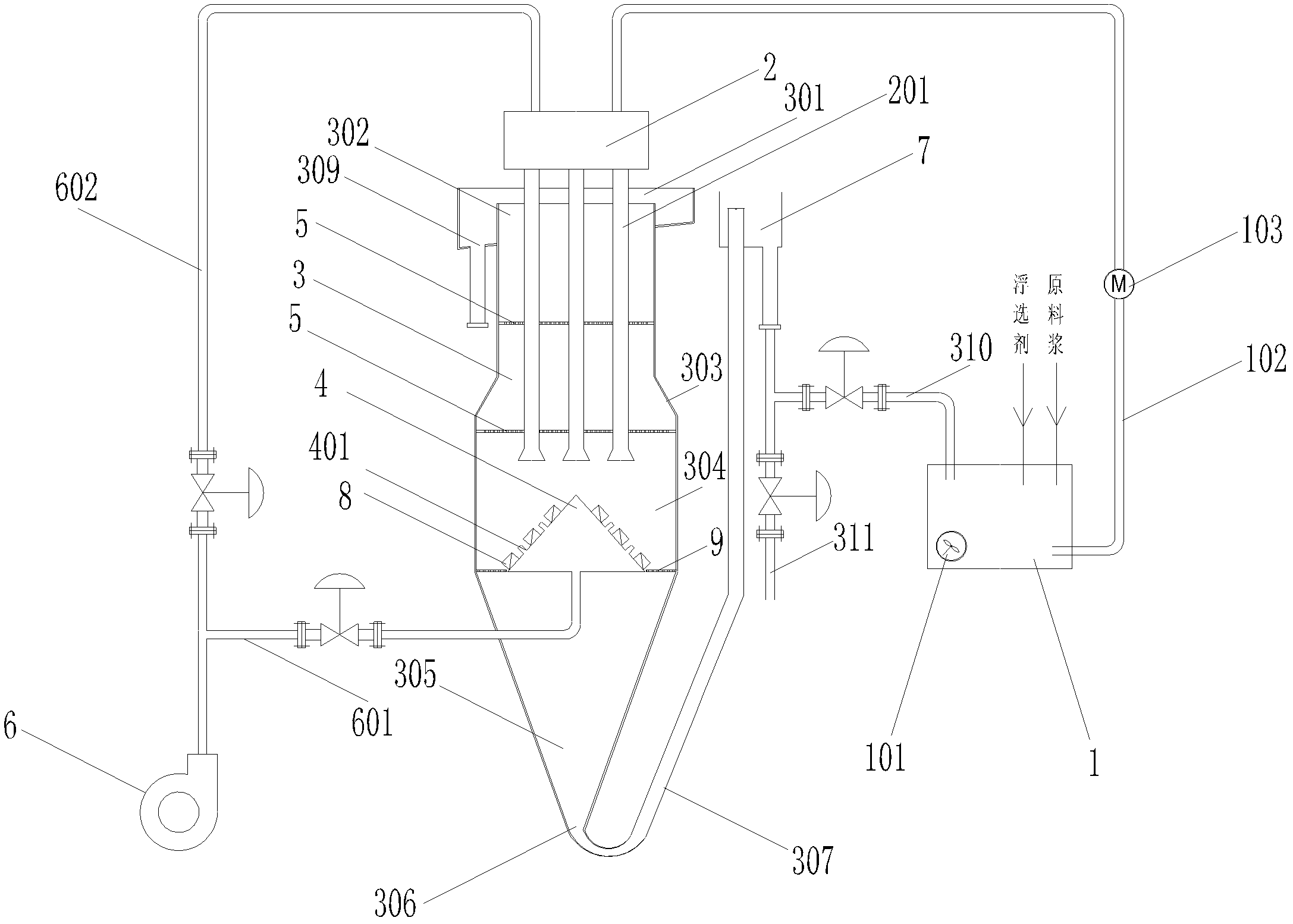

Image

Examples

Embodiment 1

[0045] Embodiment 1 of the present invention utilizes pig manure, biomass powder (bamboo sawdust), high charcoal ash, and slaked lime to produce biofuel particles with a size of 8-10 mm. It includes the following steps:

[0046] (1) Mixing raw materials in proportion, the proportion makes the final product include 70% pig manure, 25% bamboo sawdust, 1% slaked lime, 4% high carbon ash extracted from fly ash by dry weight; wherein , the peculiar smell of pig manure can be removed during the stirring process; the pig manure used has a water content of 45%, bamboo wood chips have a water content of 45%, slaked lime has a water content of 20%, and high charcoal ash has a water content of 35%;

[0047] (2) Utilize the drying machine to dry the raw materials mixed and stirred in step (1) to about 14% water content;

[0048] (3) adding a binding agent such as modified starch to the dried raw material in step (2), and stirring;

[0049] (4) Put the raw materials stirred in step (3) i...

Embodiment 2

[0070] Embodiment 2 of the present invention is similar to embodiment 1, and it utilizes pig manure to manufacture the biofuel particle that size is 5-7 millimeter, and carries out granulation with granulator, and it comprises the following steps:

[0071] (1) Raw materials are mixed in such a proportion that the final product comprises 68% pig manure, 18% bamboo sawdust, 2% slaked lime, and 12% high carbon ash extracted from fly ash by dry weight; wherein , in the process of stirring, the peculiar smell of pig manure can be removed; the used pig manure contains 52% water, bamboo sawdust contains 48% water, slaked lime contains 20% water, and high carbon ash extracted from fly ash contains 38% water;

[0072] (2) Utilize the vacuum belt dehydrator to dehydrate the mixed and stirred raw materials in step (1) to about 18% water content;

[0073] (3) adding binder such as cornstarch to the dehydrated raw material in step (2), and stirring;

[0074] (4) drying the raw materials s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com