Method for detecting silicon content in vanadium-aluminum alloy

A detection method and technology of vanadium-aluminum alloy, applied in the field of chemical analysis, can solve problems such as unsuitable low-content analysis, inability to meet the needs for determination of silicon content in vanadium-aluminum alloy, and no determination of silicon content in vanadium-aluminum alloy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention analyzes the characteristics of the vanadium-aluminum alloy sample, adding hydrochloric acid and nitric acid to decompose the sample, and the sample is completely decomposed and meets the needs of rapid analysis; V 5+ For the main interfering ions in the present invention, adding sodium sulfite to the liquid to be measured can make V 5+ Restore, thereby eliminating its interference. Additionally, removing V 5+ It is helpful to improve the accuracy of absorbance determination, and then improve the accuracy of silicon content determination.

[0015] A method for detecting silicon content in vanadium-aluminum alloys according to an exemplary embodiment of the present invention comprises the following steps:

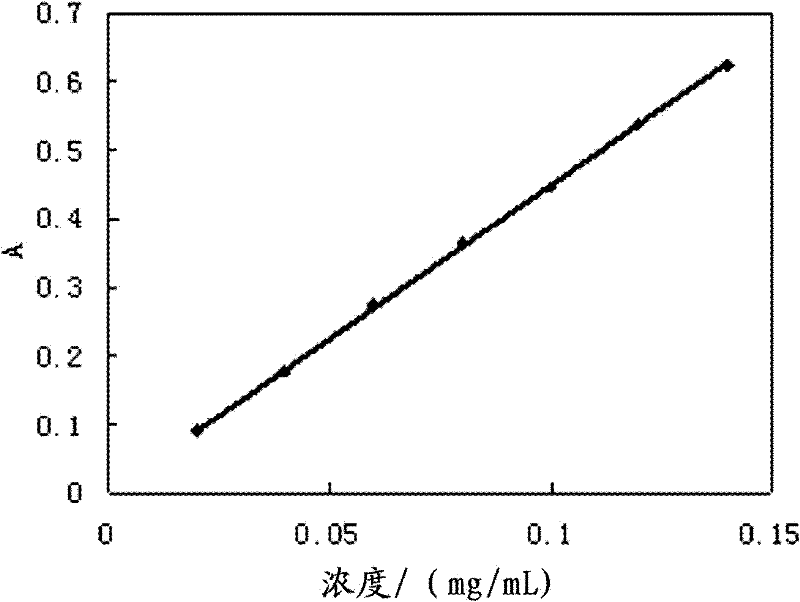

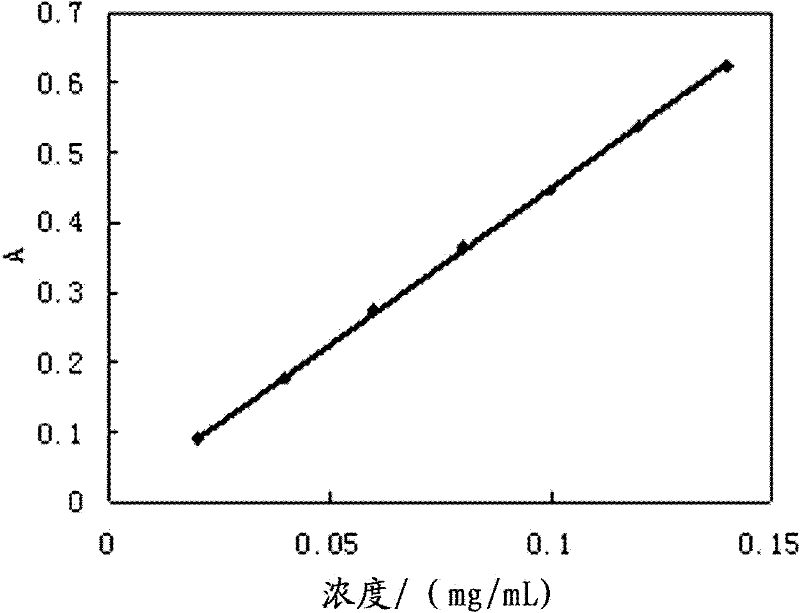

[0016] 1) Establish silicon standard solution concentration-absorbance working curve;

[0017] 2) Decompose the sample to be tested of vanadium-aluminum alloy with hydrochloric acid and nitric acid, add sodium sulfite to the solution to be tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com