Protector chip of light emitting diode and production technology thereof

A technology of light-emitting diodes and protection devices, which is applied in the field of protection device chips and production processes of light-emitting diodes, can solve problems such as inability to use light-emitting diodes to protect devices, low working voltage of light-emitting diodes, and inability to illuminate circuits, so as to improve reliability and anti-corrosion Surge capability, strong automatic recovery ability after circuit power failure, and fast switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing:

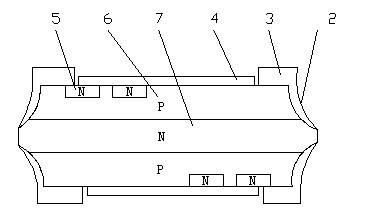

[0028] The protection device chip structure of the light emitting diode is N-P-N-P-N type.

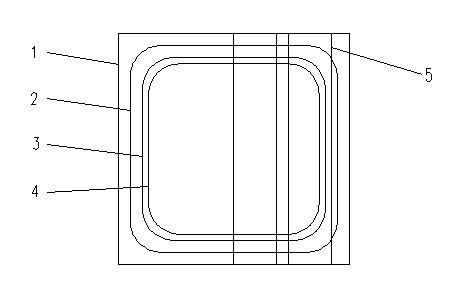

[0029] Such as figure 1 The planar structure of the chip of the protection device of the light-emitting diode is as follows: chip 1, corrosion groove 2, passivation glass 3, metal layer 4, high-concentration N region 5;

[0030] Such as figure 2 The chip sectional structure of the protection device of the light emitting diode shown is as follows: corrosion trench 2, passivation glass 3, metal layer 4, high-concentration N region 5, P region 6, and base region N7.

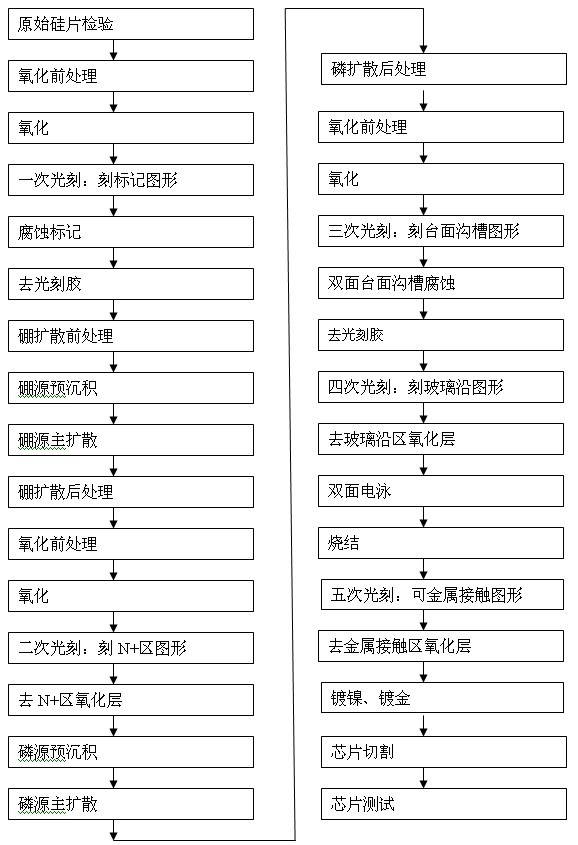

[0031] Such as image 3 The chip process flow of the protective device for the light emitting diode shown is as follows:

[0032] 1) Pre-oxidation treatment: chemically treat the surface of silicon wafers through acid, alkali, deionized water and other processes;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com