Hydrogen sulfide synthesis device

A synthesis device, hydrogen sulfide technology, applied in hydrogen sulfide, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reduced reaction efficiency, difficult to effectively control temperature, difficult industrial operation, etc., to achieve high evaporation efficiency, high temperature easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

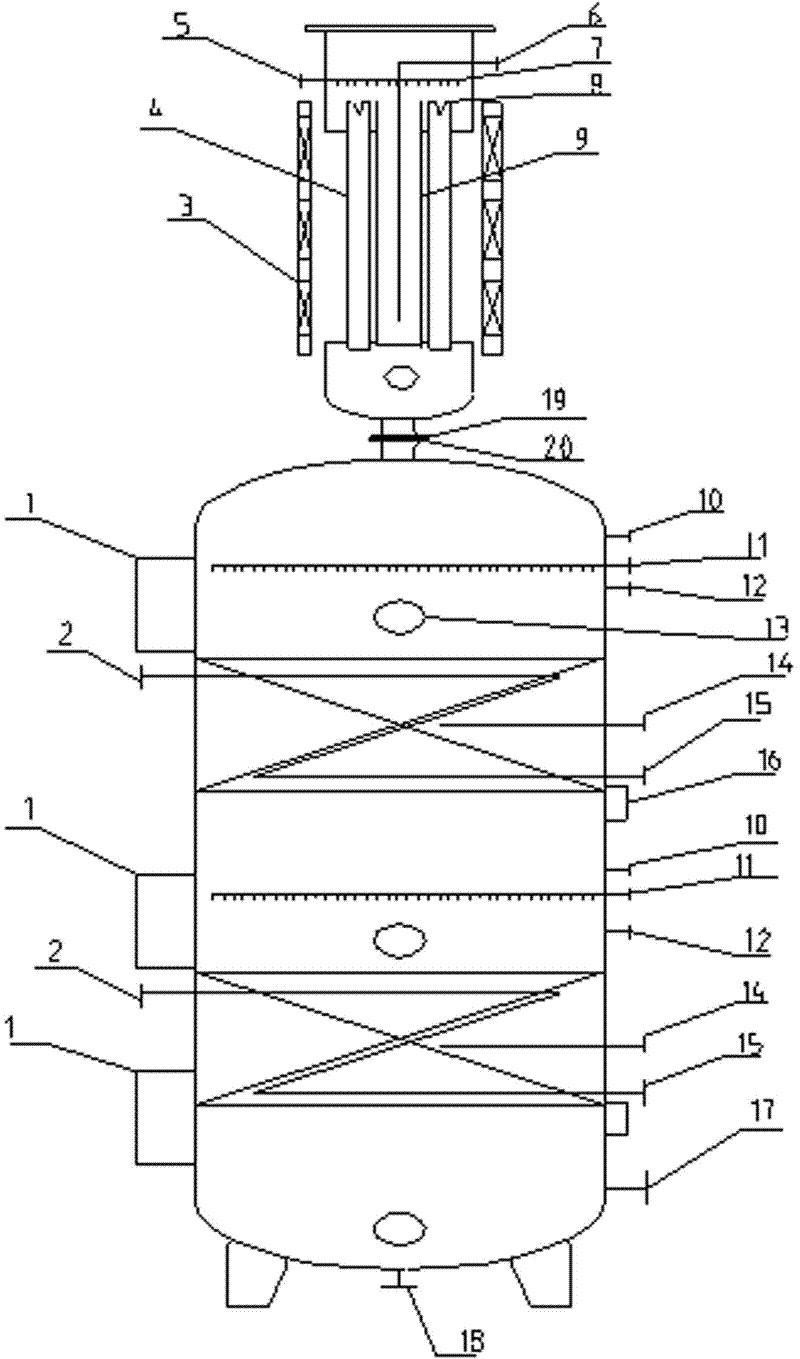

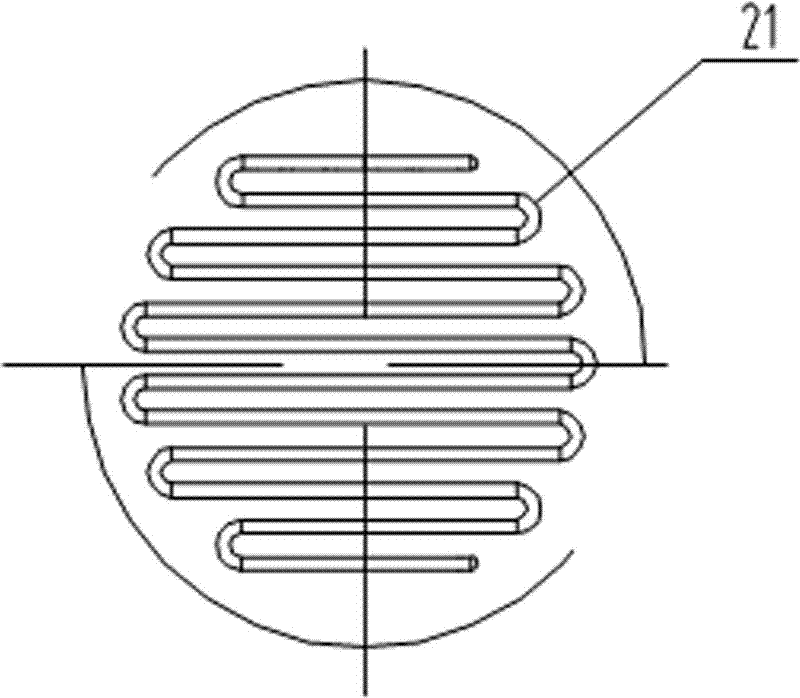

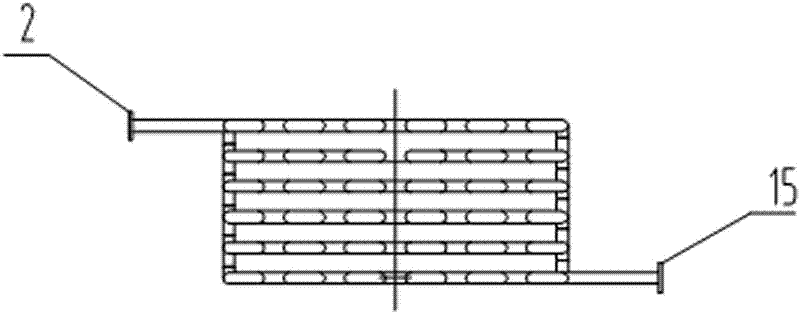

[0036] Such as figure 1 , figure 2 As shown, under the action of the electric induction heating coil, the temperature in the sulfur evaporator is 450°C, and the liquid sulfur at 140°C enters the evaporator through the sulfur feed port 5 and then evaporates and gasifies in the evaporator tube 4, and the raw material hydrogen is The evaporator tube 4 is preheated in the inner and outer tubes of different diameters, and mixed with sulfur vapor in the evaporator tube 4, the temperature rises, and enters the synthesis tower after reaching 450°C. The internal pressure of the evaporator is controlled at 0.25MPa, and the flow rate of liquid sulfur 0.54t / h, hydrogen volume 800Nm 3 / h, the power of the electric induction heating device 3 is 150kW. The hydrogen sulfide synthesis tower is equipped with two catalyst beds, and heat exchange coils 21 are installed in each layer. The reaction is carried out under high temperature and low pressure conditions. The reaction temperature is 450°...

Embodiment 2

[0038] Such as figure 1 , figure 2 As shown, under the action of the electric induction heating coil, the temperature inside the sulfur evaporator is 500°C, and the liquid sulfur at 140°C enters the evaporator through the sulfur feed port 5 and then evaporates and gasifies in the evaporator tube 4, and the raw material hydrogen is The evaporator tube 4 is preheated in the inner and outer tubes of different diameters, and mixed with sulfur vapor in the evaporator tube 4, the temperature is raised, and it enters the synthesis tower after reaching 500 ° C. The internal pressure of the evaporator is 0.5 MPa, and the flow rate of liquid sulfur is 0.9 t / h, hydrogen volume 1500Nm 3 / h, the power of the electric induction heating device 3 is 170kW. The hydrogen sulfide synthesis tower is equipped with three-stage catalyst beds, and heat exchange coils 21 are arranged in each layer. The reaction is carried out under high temperature and low pressure conditions. The reaction temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com