C3N4 preparation method

A C3N4, calcination technology, applied in the direction of nitrogen and non-metallic compounds, can solve the problems of unfavorable environmental protection and large-scale preparation, and achieve the effect of high yield, simple steps and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention provides a C 3 N 4 preparation methods, including:

[0024] Thiourea is calcined at 300-650 to obtain the product; the product includes C 3 N 4 .

[0025] Thiourea is a compound formed after the oxygen in urea is replaced by sulfur, which belongs to thioamide (RC(S)NR 2 , R is a hydrocarbon group). Due to the difference in electronegativity, despite similar structures, thiourea and urea have very different properties. Thiourea is widely used in organic synthesis. Molecular formula is shown in formula I. Because its tautomerism will intensify when heated, and with the occurrence of polycondensation, a multimer with an uncertain structure is obtained, which is not stable and will be further decomposed into C 3 N 4 .

[0026]

[0027] Formula I

[0028] According to the present invention, the calcination can be carried out under aerobic or anaerobic conditions, wherein, the calcination temperature is the C 3 N 4 The key, the temperatur...

Embodiment 1

[0035]Weigh 10.0g of urea and place it in a crucible, cover it, and calcinate it under aerobic conditions. The calcining temperature is 550°C, and the calcining time is 2h. Cool to obtain C 3 N 4 catalyst.

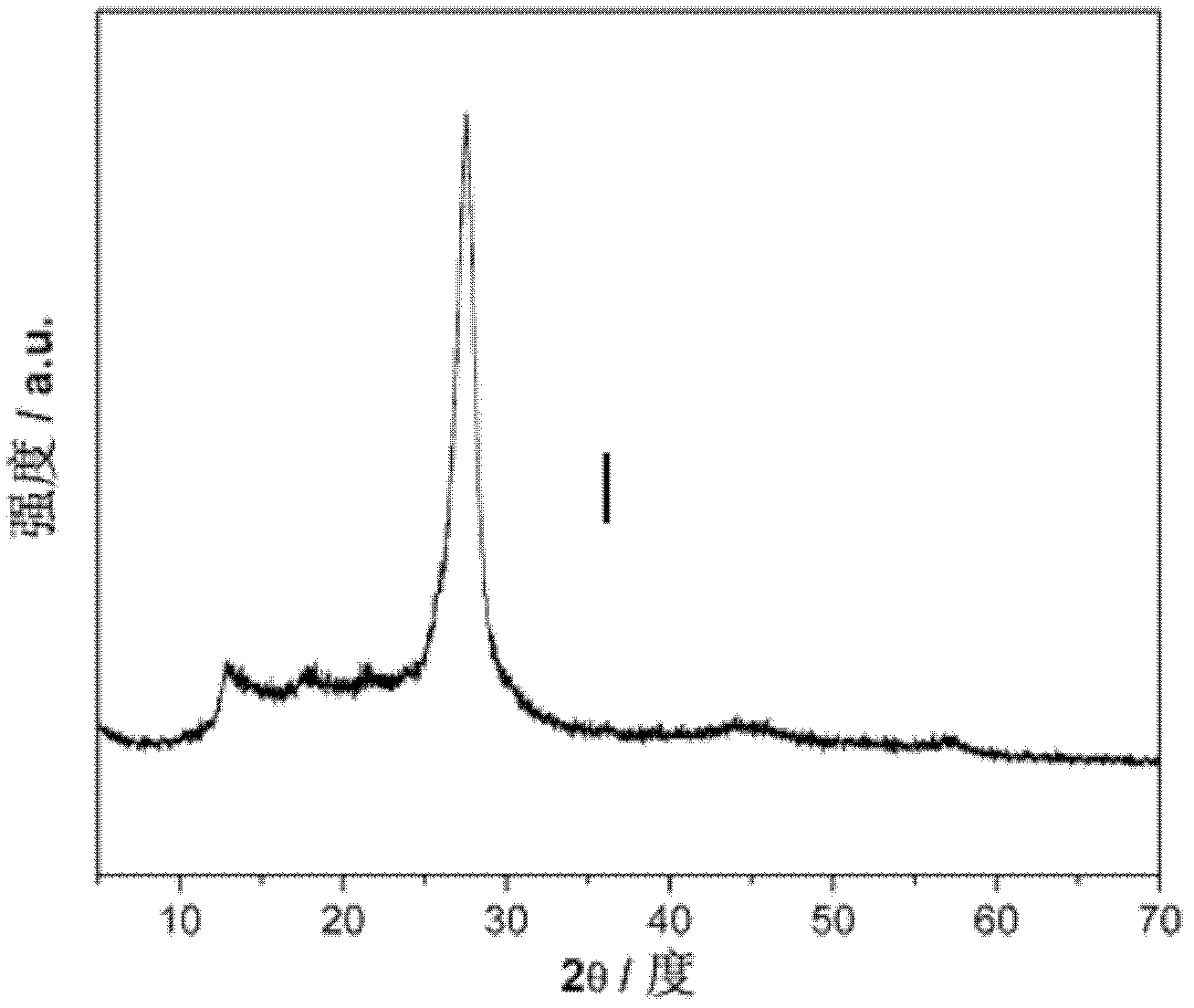

[0036] Such as figure 1 Shown, the C prepared for the implementation of the present invention 3 N 4 The XRD picture, shows that the prepared C 3 N 4 With graphite phase crystal.

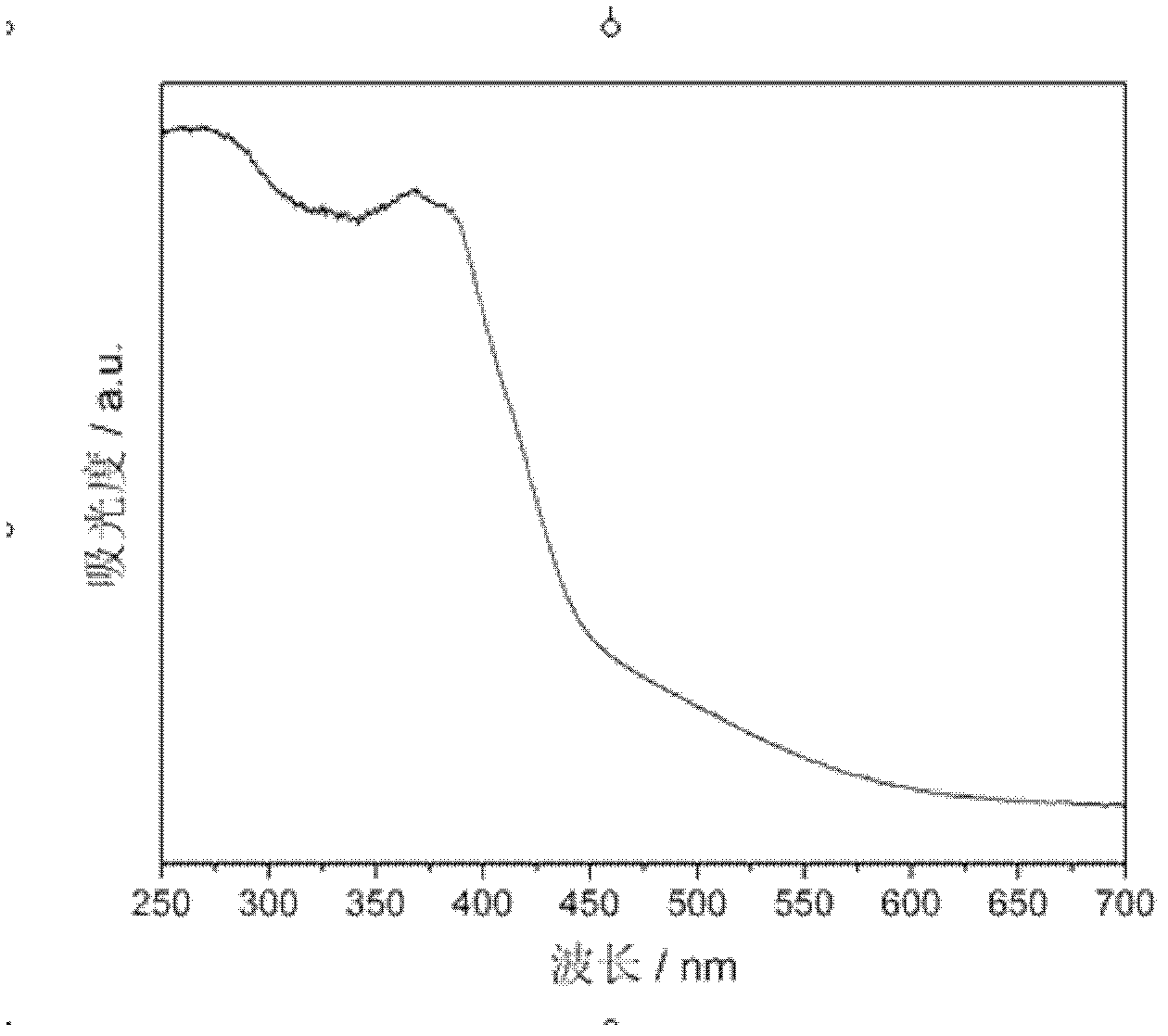

[0037] Such as figure 2 Shown, the C prepared for the implementation of the present invention 3 N 4 The UV-Vis absorption spectrum of the prepared C 3 N 4 Can absorb visible light, the maximum absorption wavelength is 650nm.

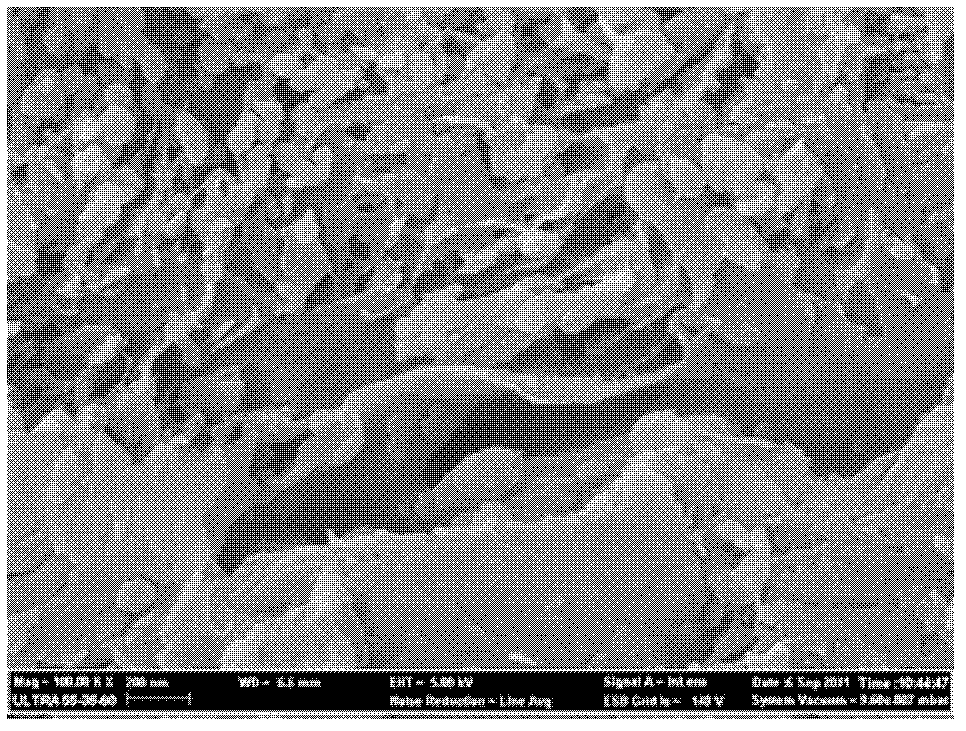

[0038] Such as image 3 Shown, the C prepared for the implementation of the present invention 3 N 4 The SEM pattern of the prepared C 3 N 4 Has a layered structure.

Embodiment 2

[0040] Weigh 10.0g of urea and put it in a crucible, calcining under aerobic conditions, the calcining temperature is 500°C, the calcining time is 4h, and cooling to obtain C 3 N 4 catalyst.

[0041] Such as Figure 4 Shown, for the C prepared in this example 3 N 4 The UV-Vis absorption spectrum of the prepared C 3 N 4 Can absorb visible light, the maximum absorption wavelength is 700nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com