Chemical vapor synthesis method for growing carbon nanotubes in mode of being attached to wall of pore channel of template

A technology of carbon nanotubes and chemical vapor phase, applied in the direction of carbon nanotubes, nanocarbon, nanotechnology, etc., can solve the problems of difficult growth of carbon nanotubes, complex process, expensive equipment, etc. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

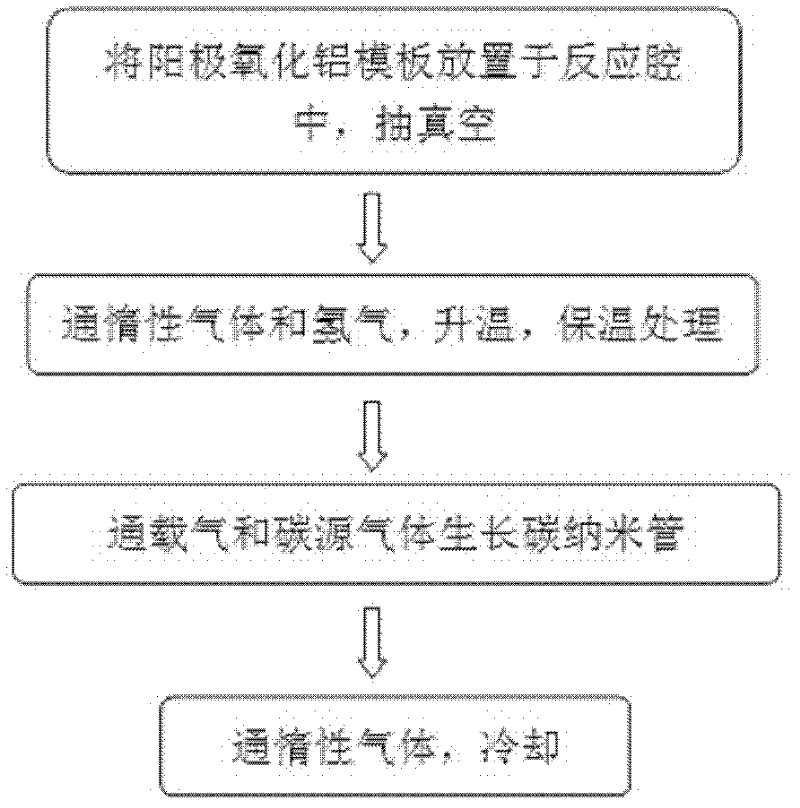

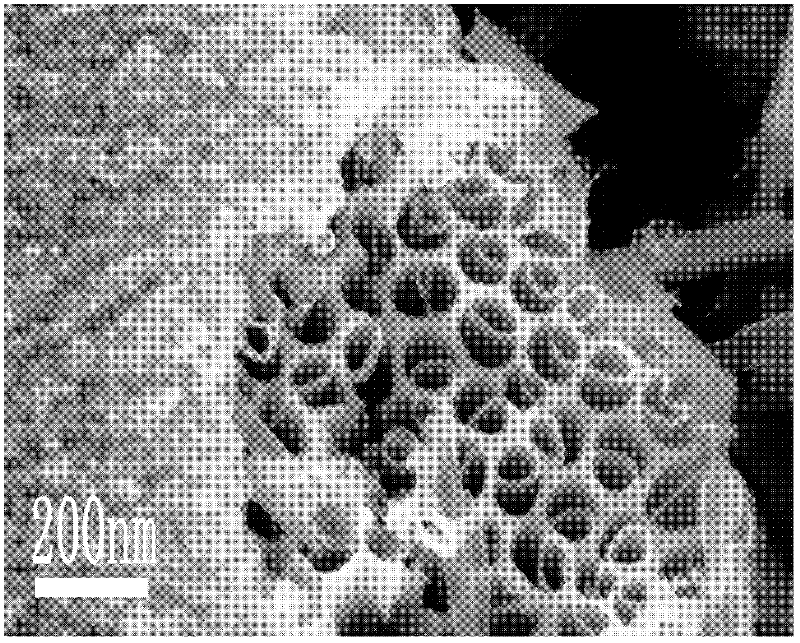

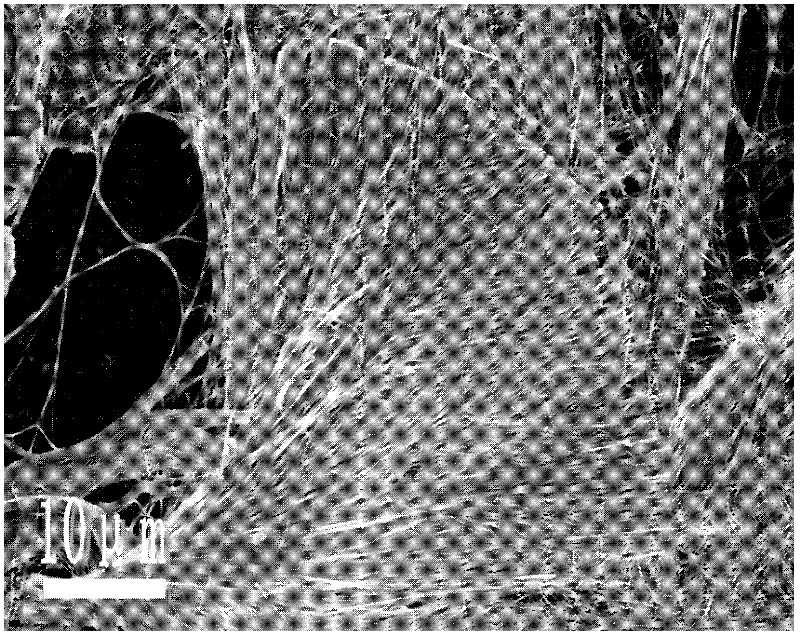

[0032] Such as figure 1 As shown, a method for growing carbon nanotubes by chemical vapor synthesis attached to the channel wall of the template includes the following steps: putting the anodized aluminum channel array template with a pore diameter of 100 nm and a thickness of 60 μm into a chemical vapor deposition vacuum device horizontal vacuum tube type In the high-temperature reaction furnace, evacuate to about 15Pa, pass in 20sccm of hydrogen and 180sccm of argon, maintain the pressure at 1000Pa, raise the temperature to 500°C, and keep the treatment time for 2h; then change the flow rate of argon to 160sccm, and then pass in 20sccm acetylene, the pressure was maintained at 1000Pa, and the reaction was carried out for 2 hours; the heating power was turned off, cooled naturally, and the sample was taken out, and the obtained product was a neat array of large-diameter carbon nanotubes, with a morphology as follows figure 2 , 3 shown.

Embodiment 2

[0034] Put the anodized aluminum channel array template with a pore size of 50nm and a thickness of 30μm into a horizontal vacuum tube high-temperature reaction furnace of a chemical vapor deposition device, and evacuate it to about 15Pa; 100Pa, raise the temperature to 700°C, and keep the treatment time for 1h; stop feeding hydrogen, change the flow rate of argon to 130sccm, feed 20sccm of acetylene, keep the pressure at 5000Pa, and react for 1h; turn off the heating power, cool down, and get the sample.

Embodiment 3

[0036] Put the anodized aluminum channel array template with a pore size of 150nm and a thickness of 60μm into a horizontal vacuum tube high-temperature reaction furnace of a chemical vapor deposition device, and vacuumize it to about 15Pa; 5000Pa, heat up to 400°C, keep the treatment time for 2h; continue to heat up to 750°C, stop feeding hydrogen, change the flow rate of argon to 160sccm, pass in 40sccm of acetylene, keep the pressure at 4000Pa, react for 2h; turn off the heating power, Cool to obtain a sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com