Method for reclaiming ammonium hydrogen carbonate from non-condensable gas of stripping tower

A technology of ammonium bicarbonate and stripping tower, applied in the direction of ammonium carbonate/acid carbonate, etc., can solve the problems of destroying the living environment of biological bacteria, environmental pollution, and affecting the effect of sewage treatment, and achieve the solution of the greenhouse effect , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

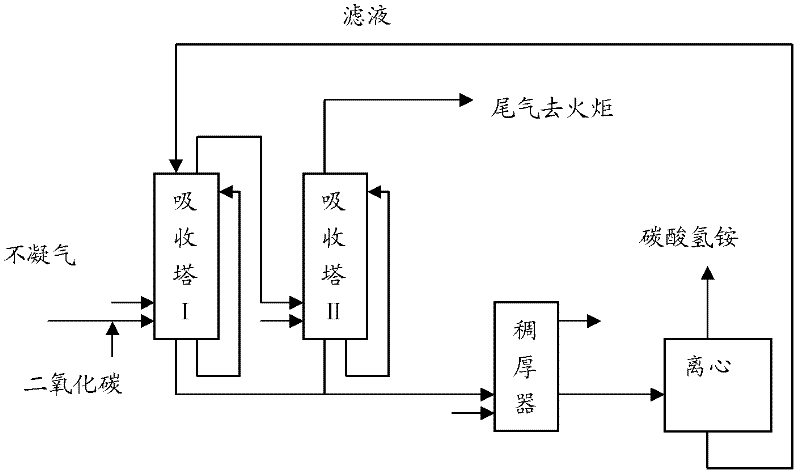

Image

Examples

Embodiment 1

[0018] Composition of non-condensable gas (V%): CO 2 34.43, H 2 14.53, CO 2 21.4, CH 4 0.05,H 2 S0.54, N 2 0.09, Ar0.06, COS0.05, NH 3 15.79, H 2 O13.06, flow rate 1128Nm 3 / h, the theoretical recovery of ammonium bicarbonate is 628.15kg / h, the actual recovery of ammonium bicarbonate is 576.01kg / h, and the recovery rate is 91.7%.

Embodiment 2

[0020] Composition of non-condensable gas (V%): CO 2 36.25, H 2 13.82, CO19.43, CH 4 0.05,H 2 S0.52, N 2 0.08, Ar0.05, COS0.05, NH 3 16.64, H 2 O13.11, flow rate 1176Nm 3 / h, the theoretical recovery of ammonium bicarbonate is 690.14kg / h, the actual recovery of ammonium bicarbonate is 637.69kg / h, and the recovery rate is 92.4%.

Embodiment 3

[0022] Composition of non-condensable gas (V%): CO 2 36.25, H 2 13.82, CO19.43, CH 4 0.05,H 2 S0.52, N 2 0.08, Ar0.05, COS0.05, NH 3 16.64, H 2 O13.11, flow rate 1176Nm 3 / h, while introducing 99% carbon dioxide 100Nm 3 / h, the theoretical recovery of ammonium bicarbonate is 690.14kg / h, the actual recovery of ammonium bicarbonate is 647.35kg / h, and the recovery rate is 93.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com