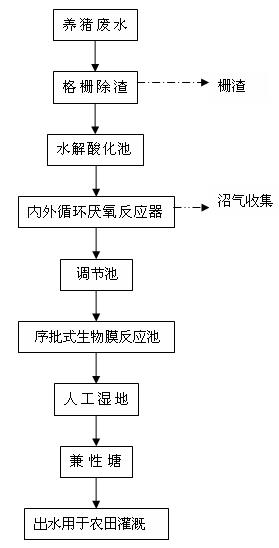

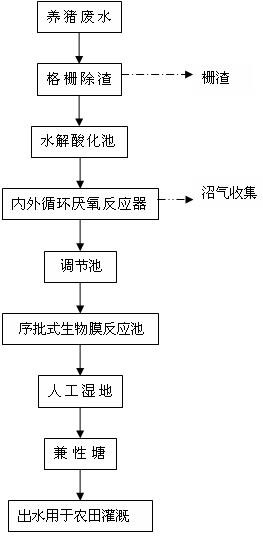

Technique for treating pig raising liquid waste by circular anaerobic reactor, sequencing batch biofilm, constructed wetland and facultative lagoon

A sequencing batch biofilm and constructed wetland technology, applied in the field of combined processes, can solve the problems of high cost and difficult treatment of pig-raising wastewater, and achieve the effect of solving high pollutant concentration, good denitrification and phosphorus removal ability, and reducing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

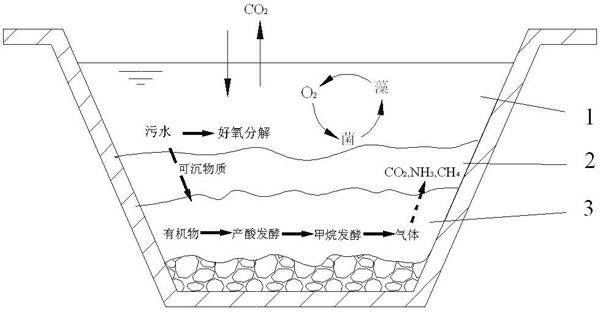

[0021] The structure of the invention includes: internal and external circulation anaerobic reactors, grids, hydrolytic acidification ponds, sequencing batch biofilm reactors, regulating ponds, artificial wetlands and facultative ponds.

[0022] This process is applied to a large-scale pig farm with a water volume of 100m 3 / d, raw water quality is COD6000~10000mg / L, NH 4 + -N500~1500mg / L, TP40~100mg / L.

[0023] ① Raw water first enters the hydrolysis acidification tank to convert complex organic pollutants into simple organic pollutants. The effluent enters the internal and external circulation anaerobic reactor, and most of the easily degradable organic matter can be removed. However, due to the release of phosphorus by phosphorus accumulating bacteria in an anaerobic environment, TP increased. The water quality of the effluent after the anaerobic process is as follows: COD400~1000mg / L, NH 4 + -N500~1500mg / L, TP55~150mg / L.

[0024] ②The anaerobic effluent enters the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com