Microcellular foamed modified glazed hollow bead insulating mortar and preparation method thereof

A technology of vitrified microbeads and thermal insulation mortar, which is applied in the field of building materials, can solve the problems of low proportion of vitrified microbeads, large difference in bulk density of vitrified microbeads, and reduced energy-saving effect, so as to improve the main mechanical properties and increase High construction yield and improved construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A microfoaming modified vitrified microbead thermal insulation mortar is prepared from the following raw materials.

[0056] Cement 35%;

[0057] Fly ash 10%;

[0058] Ash calcium powder 2.5%;

[0059] Dispersible rubber powder 2.5%;

[0060] Hydroxypropyl methylcellulose ether 0.66%;

[0061] Air-entraining agent 0.11%;

[0062] Water reducer 0.01%;

[0063] Wood fiber 0.1%;

[0064] Polypropylene fiber 0.12%;

[0065] Vitrified microbeads 49%.

[0066] Its preparation method is as follows:

[0067] 1. Preparation of Base

[0068] In the non-gravity mixer, under the opened flying knife, add all the raw materials except the vitrified microbeads according to the formula amount, and stir evenly at room temperature to obtain the base material. The stirring time is 8 minutes, and the stirring speed is 75 rpm. / minute.

[0069] 2. Preparation of modified vitrified microbead insulation mortar

[0070] Pour the base material prepared in step 1 and the vitrified mic...

Embodiment 2

[0077] A micro-foaming modified vitrified micro-bead thermal insulation mortar prepared from the following raw materials:

[0078] Cement 41%;

[0079] Fly ash 8%;

[0080] Ash calcium powder 3.2%;

[0081] Dispersible rubber powder 1.5%;

[0083] Air-entraining agent 0.25%;

[0084] Water reducer 0.05%;

[0085] Wood fiber 0.2%;

[0086] Polypropylene fiber 0.05%;

[0087] Vitrified microbeads 45.45%.

[0088] Its preparation method is as follows:

[0089] 1. Preparation of Base

[0090] In the non-gravity mixer, under the open flying knife, add all the raw materials except the vitrified microbeads according to the formula, and stir evenly at room temperature to obtain the base material. The stirring time is 8 minutes, and the stirring speed is 80 rpm. / minute.

[0091] 2. Preparation of modified vitrified microbead insulation mortar

[0092] Pour the base material prepared in step 1 and the vitrified microbeads in the formula into a...

Embodiment 3

[0099] A micro-foaming modified vitrified micro-bead thermal insulation mortar prepared from the following raw materials:

[0100] Cement 45.5%;

[0101] Fly ash 10%;

[0102] Ash calcium powder 3.15%;

[0103] Dispersible rubber powder 2.25%;

[0104] Cellulose ether 0.75%;

[0105] Air-entraining agent 0.38%;

[0106] Water reducer 0.07%;

[0107] Wood fiber 0.35%;

[0108] Polypropylene fiber 0.10%;

[0109] Vitrified microbeads 37.45%.

[0110] Its preparation method is as follows:

[0111] 1. Preparation of Base

[0112] In the non-gravity mixer, under the open flying knife, add all the raw materials except the vitrified microbeads according to the formula, and stir evenly at room temperature to obtain the base material. The stirring time is 8 minutes, and the stirring speed is 80 rpm. / minute.

[0113] 2. Preparation of modified vitrified microbead insulation mortar

[0114] Pour the base material prepared in step 1 and the vitrified microbeads in the formula...

PUM

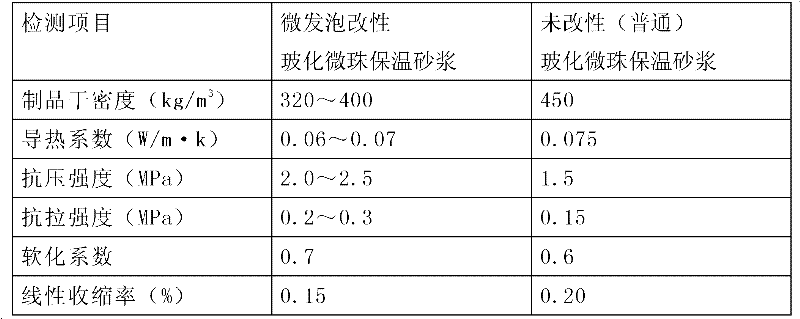

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com