Prefabricated panels and preparation method thereof

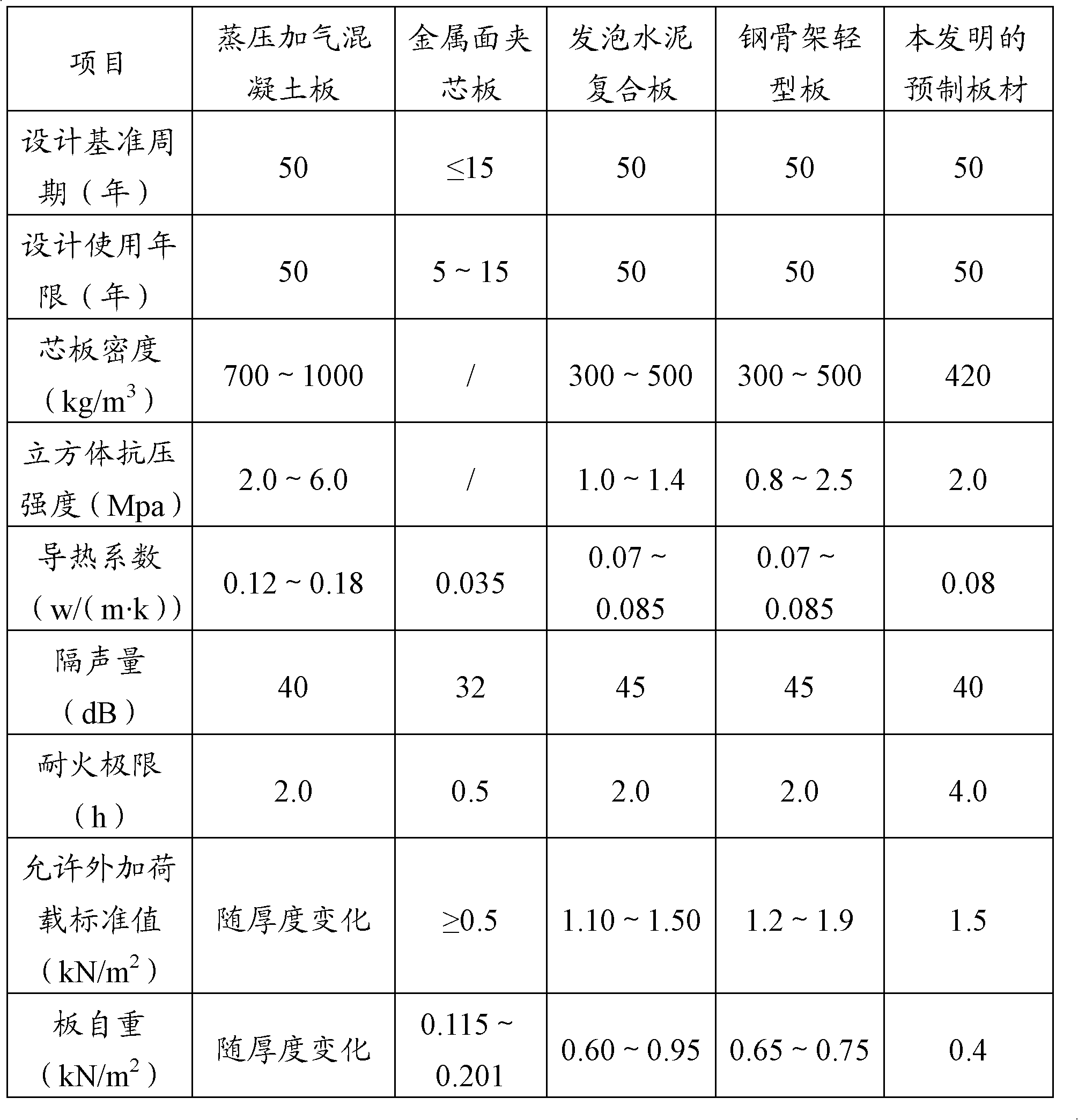

A panel and formwork technology, applied in the field of prefabricated panels and their preparation, can solve problems such as low bearing capacity, high density of autoclaved aerated concrete panels, and threats to component safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of building material provided by the invention comprises the following steps:

[0044] Put the proportioned cement, fly ash, stone-forming agent and water into the mixing tank. When a large amount of uniform slurry with suspended microbubbles appears, then put in the aggregate of the thermal insulation material, stir evenly, and get the slurry, and then use the mold again Pouring molding, the process can be fully automated production;

[0045] The proportion relationship of each component is as follows: the mass ratio of cement to fly ash is 2.0-3.5:1.0; the mass ratio of water to cement plus fly ash is 1.0-1.2:1.0; the mass ratio of cement plus fly ash to insulation material aggregate The mass ratio is 2.0-3.0:1.0; the mass ratio of cement plus fly ash to stone-forming agent is 1.0:0.03-0.05.

[0046] The method adopted in the present invention is a secondary feeding method, which is better than the method of simultaneously putting cement, fly a...

Embodiment

[0050] Put cement, fly ash, stone-forming agent and water into the mixing tank according to the secondary feeding method. After stirring for 2 to 3 minutes, a large number of suspended microbubbles appear in the slurry, put in expanded perlite, and stir evenly; The low-carbon cold-drawn steel wire mesh is fixed, and the prepared slurry is poured at one time to form a prefabricated plate with a specification of 1500×3000×100mm.

[0051] Among them, 75kg of cement, 25kg of grade II fly ash, 45.5kg of superior expanded perlite with a particle size of 1mm to 3mm, 110kg of water, 15kg of No. 42.5 sulfoaluminate cement and 60kg of No. 42.5 ordinary Portland cement mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com