Melted pelleting seaweed stable fertilizer and preparation method thereof

A technology of melt granulation and stability, applied in fertilizer mixture, fertilization device, agricultural gas emission reduction, etc., can solve the problems that restrict the popularization and application of seaweed fertilizer, uneven distribution of product nutrients, cumbersome production process, etc., and achieve the effect of increasing production Significantly, the effect of improving fertilizer utilization rate and reducing fertilizer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

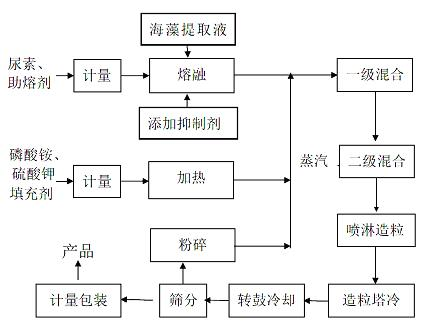

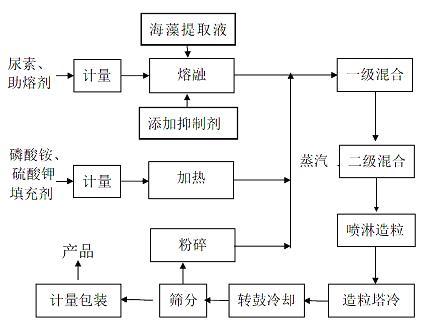

Method used

Image

Examples

example 1

[0052]520 kg of solid urea, together with 1 kg of combined urease inhibitor, 1 kg of combined nitrification inhibitor and 10 kg of concentrated seaweed extract, was heated to 136°C to form a molten liquid, and 114 kg of monoammonium phosphate, 300 kg of potassium sulfate, and 54 kg of talcum powder were added to the In the above molten liquid, stir and mix for 2-3 minutes, the slurry temperature is 110-115°C, and the slurry containing suspended solids passes through the granulator to become droplets and falls from the granulation tower with a height of 106 meters. Heat and mass transfer, cooling and solidification into small pellets of 1-4 mm to obtain granular melt granulated seaweed stabilized fertilizer.

[0053] Wherein, the combined urease inhibitor consists of N-n-butylthiophosphoric triamide (C 4 h 14 N 3 PS, nBPT), hydroquinone (C 6 h 6 o 2 , HQ) and phenyl phosphoric acid diamide (C 6 h 9 N 2 PO, PPD) are combined according to the weight ratio of 1:1:1; the co...

example 2

[0056] Take 520 kg of urea solution or melt at the outlet of the second-stage evaporator of the urea plant, the concentration is greater than 99%, and the temperature is about 140°C, add 1.0 kg of combined nitrification inhibitor, 1 kg of combined urease inhibitor, and 10 kg of concentrated seaweed extract, stir and mix, and then Add 345kg of powdered monoammonium phosphate, 100kg of potassium sulfate, 43kg of calcium powder, and 30kg of attapulgite clay, stir and mix for about 2 minutes, the slurry temperature is 110-120°C, and the slurry containing suspended solids passes through the granulator to become droplets It falls from the prilling tower with a height of 106 meters, conducts heat and mass transfer with the updraft, cools and solidifies into small pellets of 1-4 mm, which is granular melt granulated seaweed stable fertilizer.

[0057] Wherein, the combined urease inhibitor consists of N-n-butylthiophosphoric triamide (C 4 h 14 N 3 PS, nBPT), hydroquinone (C 6 h 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com