Polishing solution used for precision machining of optical communication ZrO2 ceramic stub and preparation method thereof

A ceramic ferrule and precision machining technology, which is applied in the field of polishing liquid, can solve the problems of uncoordinated polishing efficiency and polishing precision, and can not achieve the polishing effect, and achieve the effects of easy dispersion, easy cleaning, and good application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

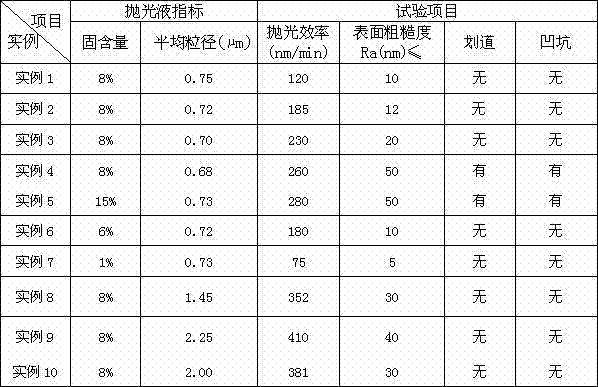

Examples

example 1

[0034] Example 1 Optical communication Zr0 2 Polishing liquid for precision machining of ceramic ferrule and preparation method thereof

[0035] Take 51.2 grams of CeO 2 (average particle size of 0.78μm) and 12.8 grams of Al 2 o 3 (average particle size is 0.5μm) micropowder, add 300 grams of deionized water and 0.32 grams of nitric acid, stir and disperse in the stirring disperser for 0.5h, add 1.6 grams of glycerol, 2.4 grams of polyvinyl alcohol derivatives, 0.16 grams of nonyl Phenol polyoxyethylene ether and 431 grams of deionized water, continue to stir and disperse for 2.0 hours, add triethanolamine to adjust the pH value to 4.5, disperse by ultrasonic waves for 20 minutes, and sieve to obtain the solid content (CeO 2 、Al 2 o 3 Micropowder) is a suspension solution of 8.0%wt, and the viscosity of the dispersion is 0.015Pa.s, which is the polishing solution of the present invention.

example 2

[0036] Example 2 Optical communication Zr0 2 Polishing liquid for precision machining of ceramic ferrule and preparation method thereof

[0037] Take 48 grams of CeO 2 (average particle size of 0.78μm) and 16 grams of Al 2 o 3 (average particle size of 0.5 μm) micropowder, add 300 grams of deionized water and 0.32 grams of nitric acid, stir and disperse in a stirring disperser for 0.5 hours, add 1.6 grams of glycerol, 2.4 grams of polyvinyl alcohol, 0.16 grams of nonylphenol poly Oxyethylene ether and 431 grams of deionized water, continue to stir and disperse for 2.0 hours, adjust the pH value to 4.5 with triethanolamine, disperse by ultrasonic waves for 20 minutes, and sieve to obtain a suspension solution with a solid content of 8.0%wt. The viscosity of the dispersion is 0.016Pa. s is the polishing liquid of the present invention.

example 3

[0038] Example 3 Optical communication Zr0 2 Polishing liquid for precision machining of ceramic ferrule and preparation method thereof

[0039] Take 42.6 grams of CeO 2 (average particle size of 0.78 μm) and 21.4 grams of Al 2 o 3 (average particle size of 0.5 μm) micropowder, add 300 grams of deionized water and 0.32 grams of nitric acid, stir and disperse in a stirring disperser for 0.5 hours, add 1.6 grams of glycerol, 2.4 grams of polyvinyl alcohol, 0.16 grams of nonylphenol poly Oxyethylene ether and 431 grams of deionized water, continue to stir and disperse for 2.0 hours, adjust the pH value to 4.5 with triethanolamine, disperse by ultrasonic wave for 20 minutes, and sieve to obtain a suspension solution with a solid content of 8.0%wt. The viscosity of the dispersion is 0.015Pa. s is the polishing liquid of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com