Method for preparing fructooligosaccharide by using baffled bioreactor

A bioreactor and fructooligosaccharide technology, which is applied in specific-purpose bioreactors/fermenters, biochemical equipment and methods, bioreactor/fermenter combinations, etc., can solve the difficulty of separation and purification in the subsequent process. , high equipment investment cost, large resistance of sucrose solution, etc., to achieve the effect of eliminating bacterial contamination, less equipment investment, and avoiding mechanical stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment is an example of a baffled bioreactor for the preparation of fructooligosaccharides.

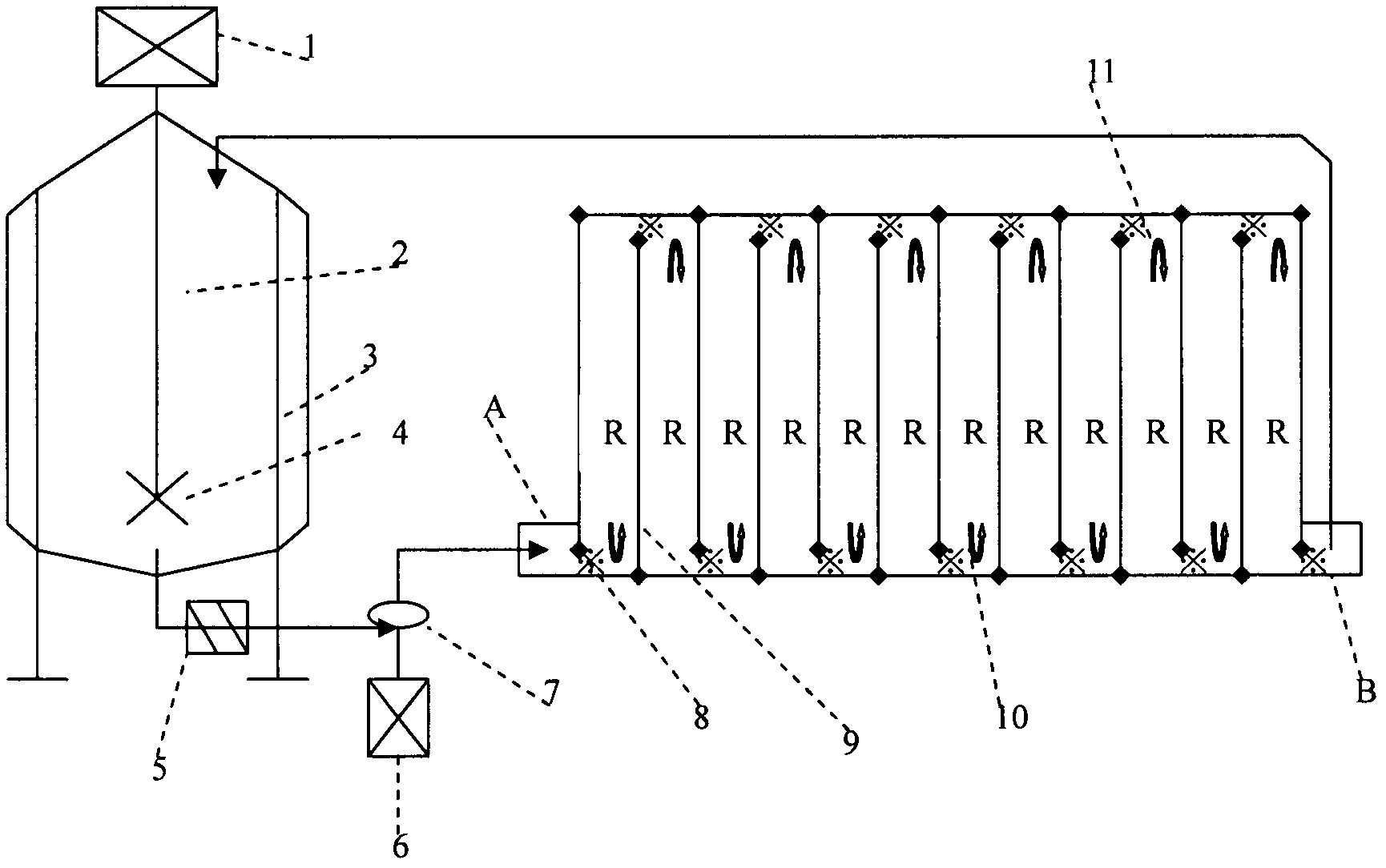

[0020] The baffle bioreactor according to the present invention consists of a first motor 1, a second motor 6, a cold and hot cylinder 2, an external heating interlayer 3, a stirring paddle 4, a cooler 5, a beverage pump 7, a stainless steel filter screen 8, The baffle plate 9, the baffle plate reaction chamber R, the reaction solution inlet A and the reaction outlet B constitute.

[0021] The specific connection method: the bottom of the hot and cold cylinder 2 is connected to the cooler 5 and the beverage pump 7, and the beverage pump 7 is connected to the reaction liquid inlet A through a stainless steel tube. The sucrose solution enters the baffle plate reaction chamber R from the reaction liquid inlet A through the stainless steel filter screen 8, and is baffled in the flow direction under the action of the baffle plate 9. Inside hot cylinder 2. and is the fl...

Embodiment 2

[0023] at 12m 3 Add 6.05T sucrose and 6T purified water to the hot and cold cylinder, the concentration of sucrose solution measured by refractometer is 50% (W / W), raise the temperature to 35°C, adjust the pH value to 7.0, and connect 12 baffle bioreactors in series , the volume of each baffle bioreactor is 0.2m 3 , adding 15% of the volume of each baffle bioreactor with a flow rate of 0.5m 3 / h, continuous cycle 20h, HPLC detection results in fructooligosaccharide content of 58.3%, through filtration, sterilization, concentration and other processes to obtain fructooligosaccharide products in line with GB / T23528-2009.

Embodiment 3

[0025] at 15m 3 Add 5.4T of sucrose and 9.75T of purified water into the hot and cold cylinder, the concentration of the sucrose solution measured by the refractometer is 35% (W / W), raise the temperature to 45°C, adjust the pH value to 4.0, and connect the 3-stage baffles in series for biological reaction device, each baffle bioreactor volume is 2m 3 , the amount of immobilized cell biocatalyst containing fructosyltransferase is 30% of the volume of each baffle bioreactor, and the flow rate is 2.0m 3 / h, continuous cycle 8h, HPLC detection results in fructooligosaccharide content of 64.3%, through filtration, sterilization, concentration and other processes to obtain fructooligosaccharide products in line with GB / T23528-2009.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com