Sweetcane bark fiber and preparation method thereof

A sugarcane peel and fiber technology, applied in the direction of chemical production of bast fibers, can solve the problems of deterioration of fiber mechanical properties, time-consuming and energy-consuming, long acid-base action time, etc., and achieves small dispersion of length and linear density, mechanical The effect of good performance and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

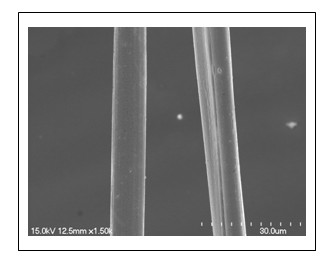

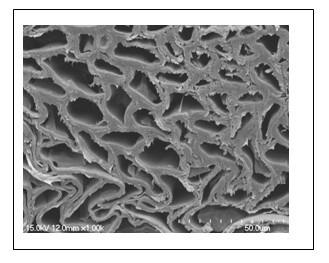

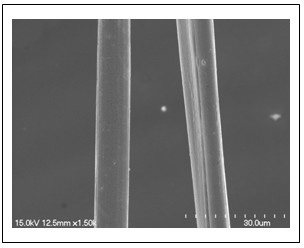

Image

Examples

Embodiment 1

[0022] Cut sugarcane bark into small sections about 70 mm in length and wash them with clean water.

[0023] Take an appropriate amount of sugarcane peel and add it to clean water, the bath ratio is 1:50, put it in a water bath and boil for 1 hour, replace with new clean water and boil for another 2 hours, then change the water and boil for 1 hour. Take out the sugarcane skin and wash it, put it in a 55°C oven and dry it for later use.

[0024] Take the cleaned and dried sugarcane bark for fiber extraction according to the following process:

[0025] Take 30g of sugarcane skin, put it into 600ml of hydrochloric acid and formic acid mixed solution, the solution contains 15ml of hydrochloric acid with a mass concentration of 36-38%, and 60ml of formic acid with a mass concentration of 88%, stir at 80°C for 60min; take out the solid Wash it with water, put it into 600ml of NaOH solution with a mass concentration of 10%, and stir it at 75°C for 120 minutes; take out the fiber for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com