Method for the preparation of a heat stable oxygen carrier-containing pharmaceutical composition

A thermally stable, oxygen carrier technology, applied in the direction of drug combinations, pharmaceutical formulations, medical raw materials derived from mammals, etc., can solve the unacceptable high percentage of dimer units, and the hemoglobin composition cannot be satisfactorily administered to mammals And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Method overview

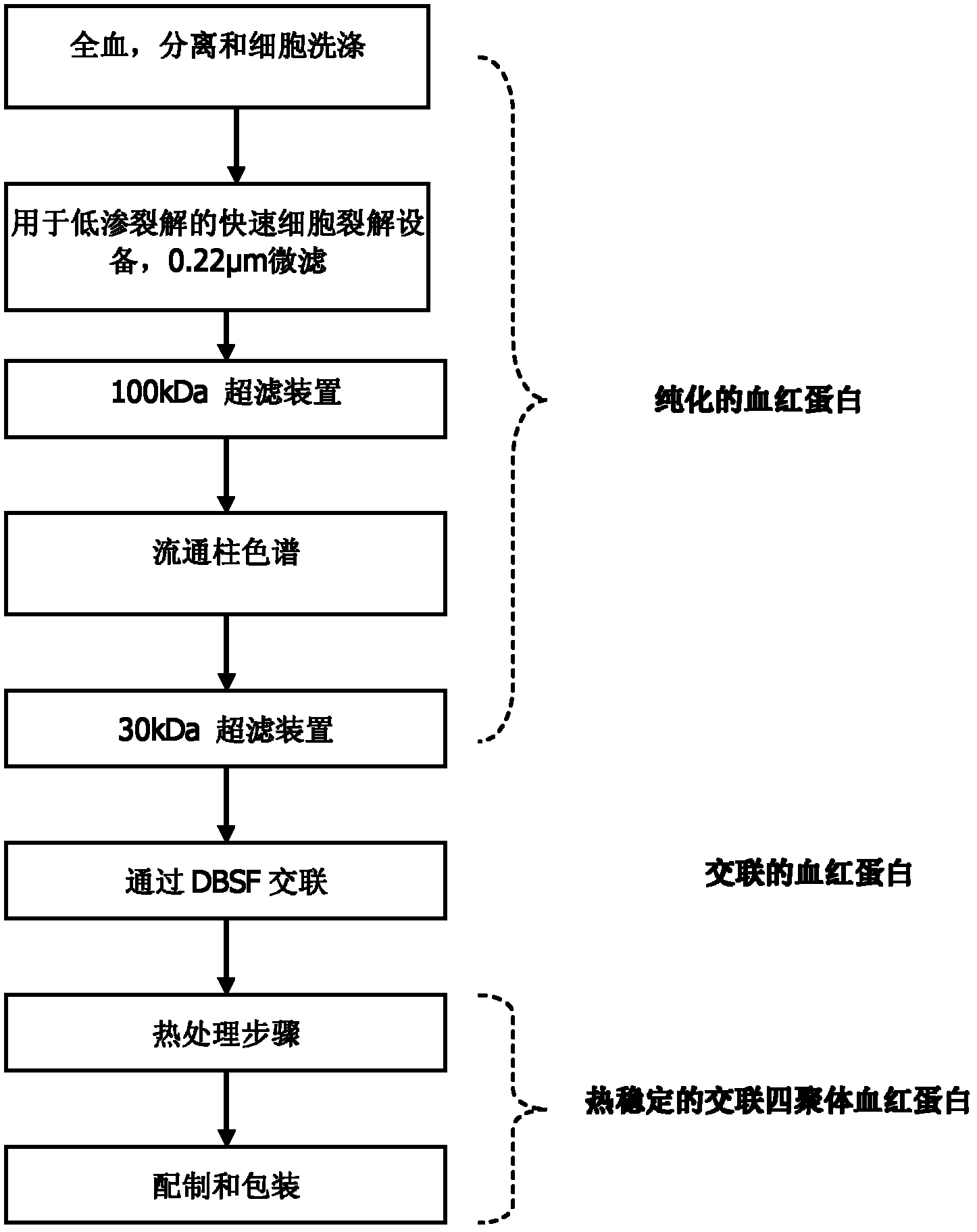

[0078] A schematic flow diagram of the method of the present invention is illustrated in figure 2 middle. Bovine whole blood was collected in closed sterile containers / bags containing 3.8% (w / v) sodium citrate solution as anticoagulant. The blood is then mixed immediately and thoroughly with sodium citrate solution to inhibit blood clotting. Red blood cells (RBCs) are separated from plasma and other smaller blood cells and collected by an apheresis mechanism. A "cell washer" was used with a gamma sterilized disposable centrifuge bowl for this step. RBCs were washed with an equal volume of 0.9% (w / v sodium chloride) saline.

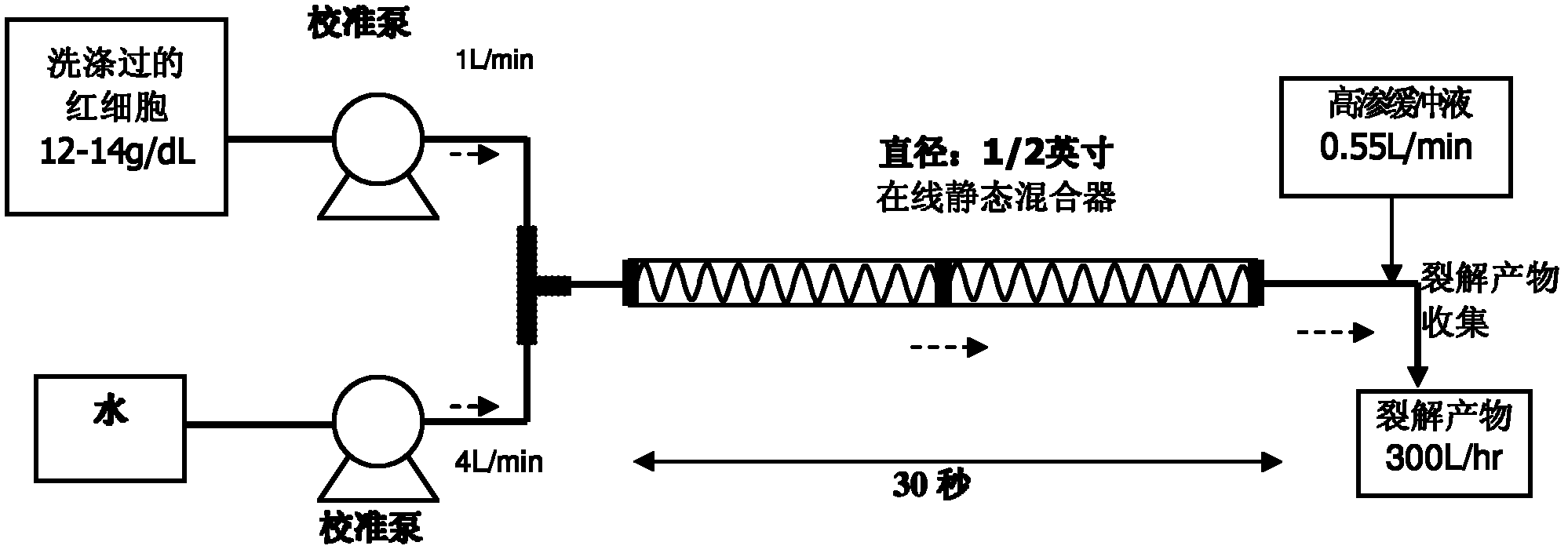

[0079] Washed RBCs are lysed by applying a hypotonic shock to the red blood cell (RBC) cell membrane to release the hemoglobin content. For this purpose, use the image 3 A dedicated rapid cell lysis device for RBC lysers. After RBC lysis, hemoglobin molecules were separated from other proteins by tangential flow ultrafiltr...

Embodiment 2

[0082] Timed & Controlled Hypotonic Lysis and Filtration

[0083]Fresh bovine whole blood was collected and shipped under chilled conditions (2-10°C). Red blood cells were separated from plasma by a cell washer followed by 0.65 μm filtration. After washing the red blood cell (RBC) filtrate with 0.9% saline, the filtrate was disrupted by hypotonic lysis. by using image 3 The rapid cell lysis device drawn in the paper for hypotonic lysis. The rapid cell lysis device includes a static mixer to aid in cell lysis. An RBC suspension with controlled hemoglobin concentration (12-14 g / dL) was mixed with 4 volumes of purified water to create a hypotonic shock to the RBC cell membrane. The timing of the hypotonic shock is controlled to avoid undesired lysis of leukocytes and platelets. The hypotonic solution is passed through the static mixer portion of the rapid cell lysis device for 2-30 seconds or a time otherwise sufficient to lyse red blood cells, and preferably 30 seconds. T...

Embodiment 3

[0086] Virus clearance studies on stroma-free hemoglobin solutions

[0087] In order to prove the safety of the product of the present invention, the virus clearance ability of (1) 0.65 μm diafiltration step and (2) 100 kDa ultrafiltration step was demonstrated by virus verification study. We implemented both methods with scaled-down small-scale reaction systems to which different model viruses were artificially added, such as encephalomyocarditis virus, pseudorabies virus, bovine viral diarrhea virus (bovine viral diarrhea virus) and bovine parvovirus (bovine parvovirus). In this study, four types of viruses were used (see Table 3). These viruses differ in their biophysical and structural characteristics, and they display differences in their resistance to physical and chemical agents or treatments.

[0088] table 3

[0089]

[0090] The verification scheme is briefly shown in Table 4 below.

[0091] Table 4

[0092]

[0093] Table 5 below summarizes the logarithmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com