Pyrethrin hot fogging agent and preparation method and application thereof

A technology for pyrethrins and thermal mist, which is applied in the field of thermal mist of natural pyrethrin biopesticides and its preparation, which can solve the problems of low use efficiency, environmental pollution, and few types, and achieve low cost, economical use of medicines, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

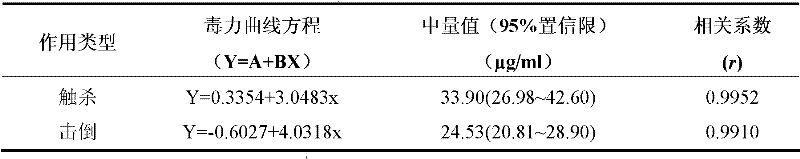

Image

Examples

Embodiment 1

[0048] The preparation method of pyrethrin thermal mist agent comprises the following steps:

[0049] Take 5 kg of active ingredients (being pyrethrin I and pyrethrin II; the same below) with a mass content of 25% pyrethrins (prepared according to the method disclosed in Chinese patent CN 1185204C; the same below), 10 kg of castor oil polyoxyethylene ether, Mix 1kg of butanoic ether, 1kg of bis(2,2,6,6-tetramethyl-4-piperidine) sebacate, 5kg of ethylene glycol, 3kg of p-dichlorobenzene and 75kg of solvent naphtha 150# (S150) Add it into the preparation kettle, stir and prepare for 1 hour until uniform, filter through a carbon steel pipeline filter press or a ceramic press filter, and send it to a storage tank for finished product packaging to obtain pyrethrin hot spray.

[0050] The pyrethrin hot mist obtained in this embodiment is a homogeneous oily liquid without visible sediment and suspended matter; the moisture content is 0.10-0.15%, and the acidity (in terms of H 2 SO ...

Embodiment 2

[0052] The preparation method of pyrethrin thermal mist agent comprises the following steps:

[0053]Get active ingredient mass content and be 70% natural pyrethrin former drug 2kg, alkyl alcohol polyoxyethylene ether 5kg, butanobuterol 0.5kg, bis(2,2,6,6-tetramethyl-4-piperidine) 0.5kg of sebacate, 2kg of ethylene glycol, 3kg of p-dichlorobenzene and 200# (S200) 87kg of solvent oil are mixed and added to the preparation kettle, stirred for 1 hour until uniform, and passed through a carbon steel pipeline filter or ceramic Press the filter to filter, send it to the storage tank for finished product packaging, and obtain pyrethrin thermal spray.

[0054] The pyrethrin hot mist obtained in this embodiment is a homogeneous oily liquid without visible sediment and suspended matter; the moisture content is 0.15-0.18%, and the acidity (in terms of H 2 SO 4 Gauge) 0.09-0.15%, viscosity 7.50-8.00×10 -3 Pa·s, flash point 95.00-100.00°C, thermal storage (14 days at 54±2°C) and cold st...

Embodiment 3

[0056] The preparation method of pyrethrin thermal mist agent comprises the following steps:

[0057] Get active ingredient mass content and be 50% natural pyrethrin former medicine 0.5kg, alkyl alcohol polyoxyethylene ether 5kg, sorbate 5kg, synergistic ether 0.1kg, 95% abamectin 0.1kg, double (2, 0.5kg of 2,6,6-tetramethyl-4-piperidine) sebacate, 1kg of ethylene glycol, 3kg of p-dichlorobenzene and 84.8kg of first-line oil (Maoming Maolong Chemical Co., Ltd.) are mixed and added to the preparation kettle , stir and modulate for 1 hour until uniform, filter through a carbon steel pipeline filter press or a ceramic filter press, and send it into a storage tank for finished product packaging to obtain pyrethrin hot spray.

[0058] The pyrethrin hot fog agent obtained in this embodiment is a homogeneous oily liquid without visible sediment and suspended matter; the moisture content is 0.09-0.13%, and the acidity (in terms of H 2 SO 4 meter) 0.12-0.15%, viscosity 8.15-8.45×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com