Glycyrrhiza polysaccharide granules and preparation method thereof

A technology of licorice polysaccharides and granules, which is applied in the field of traditional Chinese medicine formula granule health food, can solve the problems of licorice polysaccharides in the field of research and development of health care products, etc., and achieve obvious health care functions, convenient use, and obvious effects of immunomodulatory activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Preparation of licorice polysaccharide

[0022] (1) Obtaining of licorice aseptic seedlings: select licorice seeds full of particles and dark green, stir and sterilize the seeds on a magnetic stirrer with 10% sodium hypochlorite, the rotating speed is 300r / min, and the temperature is 25°C. Bacteria time 30min, MS culture containing 3% sucrose, pH 5.9 before sterilization, inoculated in a 50ml Erlenmeyer flask containing MS solid medium, placed in a light incubator at 25°C, and cultivated for 30 days to obtain licorice sterile seedlings .

[0023] (2) Acquisition of licorice callus: the licorice callus was induced from the hypocotyls of the aseptic seedlings of licorice, and after several times of selection and subculture, the growth state was stable. The subculture medium of callus was MS medium, supplemented with 2,4-D (1 mg·L -1 ), NAA (1mg·L -1 ), 6-BA (0.2mg·L -1 ), 3% sucrose, pH 5.9 before sterilization, subculture cycle 28 days.

[0024] (3) Obtaining licori...

Embodiment 1

[0027] Take licorice suspension cells as raw material, take 2kg of cell powder, add 20 times the mass of licorice cell powder in water, soak for 12 hours, heat water bath for extraction, temperature 100°C, extract for 1 hour, repeat extraction twice, concentrate to a certain volume, add 4 times the volume Measure absolute ethanol, let it stand at 4°C for 12h, remove the supernatant, remove protein by sevage method, blow dry at 45°C for 24h, and grind to obtain licorice polysaccharide powder.

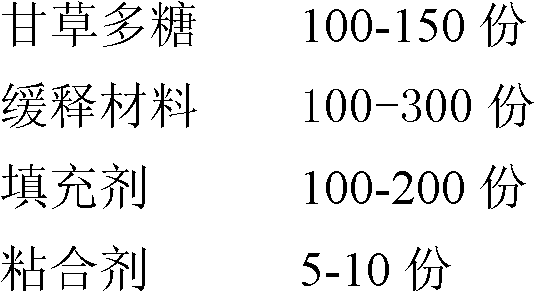

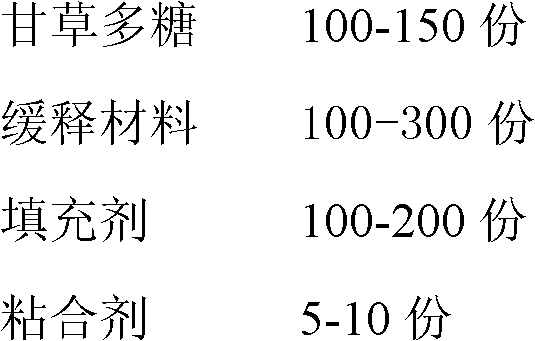

[0028] Take 100g of the above-mentioned licorice polysaccharide, 200g of hydroxypropyl methylcellulose, and 150g of lactose, mix well, pass through a 100-mesh sieve, add 20g of 1-5% ethyl cellulose ethanol solution, dry at 60°C for 5 hours, and then pass through a 20-mesh sieve Whole the grains to obtain the licorice polysaccharide granule preparation.

Embodiment 2

[0030] Take licorice suspended cells as raw material, take 2kg of cell powder, add 15 times the mass of licorice cell powder in water, soak for 5 hours, heat water bath for extraction, temperature 100°C, extract for 3 hours, repeat extraction once, concentrate to a certain volume, add 4 times the volume Measure absolute ethanol, let stand at 4°C for 12h, remove the supernatant, remove protein by sevage method, air-dry at 45°C for 24h, grind to obtain white licorice polysaccharide powder.

[0031] Take 100g of the above-mentioned licorice polysaccharide, 200g of ethyl cellulose, and 150g of mannitol, mix well, pass through a 100-mesh sieve, add 20g of 1-5% ethanol solution of ethyl cellulose, dry at 60°C for 5 hours, and then pass through a 20-mesh sieve Granules to obtain licorice polysaccharide granule preparations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com