Method for extracting and separating laminarin with low molecular weight and application thereof in cigarette products

A technology of kelp polysaccharide and low molecular weight, which is applied in the fields of application, tobacco, and tobacco preparation. It can solve the problems of improving sensory characteristics, and achieve the effects of improving smoking quality, controlling viscosity, and improving smoke quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Wash the kelp with sand removal, dry it, pulverize it, and pass it through a 40-mesh sieve to obtain the extracted raw materials;

[0026] (2) Add acetic acid solution with a pH value of 2 to the extraction raw materials, add 35 times the weight of the dry kelp powder, extract at 115 ° C for 4 hours, filter, and separate the kelp residue to obtain an extract, and adjust the pH of the extract with potassium hydroxide value to 7.0;

[0027] (3) vacuum-concentrating the extract to 1 / 5 of the original volume to obtain a concentrated solution;

[0028] (4) Add ethanol to the concentrated solution, after mixing evenly, the final concentration of ethanol is 80% (v / v), stand at 2 °C for 8 hours, filter, remove the supernatant part, and precipitate the polysaccharide;

[0029] (5) Collect the precipitate, freeze-dry it, and obtain laminarin 1# with a molecular weight of 20711 Da, which is light brown.

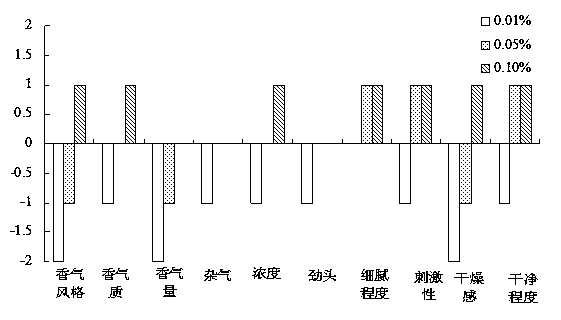

[0030] The sample was added to the cigarette in an amount of 0.1% of t...

Embodiment 2

[0032] (1) Wash the kelp to remove sand, dry it, pulverize it, and pass it through a 20-mesh sieve to obtain the extracted raw materials;

[0033] (2) Add acetic acid solution with a pH value of 3 to the extraction raw materials, add 40 times the weight of the dry kelp powder, extract at 125 ° C for 2 hours, filter, and separate the kelp residue to obtain an extract, and adjust the pH of the extract with potassium hydroxide value to 7.0;

[0034] (3) ultrafiltration of the extract obtained in step (2) with a membrane with a molecular weight cut-off of 10,000 Daltons to collect the permeate part;

[0035] (4) vacuum-concentrating the ultrafiltration permeate to 1 / 6 of the original volume to obtain a concentrated solution;

[0036] (5) Add ethanol to the concentrated solution, after mixing evenly, the final concentration of ethanol is 85% (v / v), stand at 0 °C for 6 hours, filter, remove the supernatant part, and precipitate the polysaccharide;

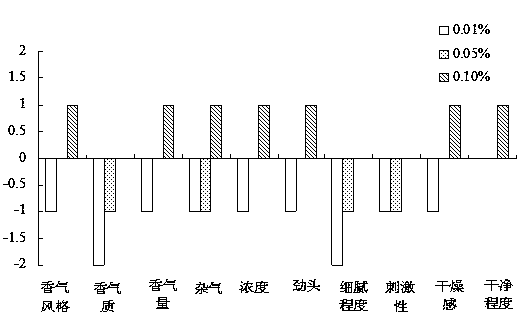

[0037] (6) Collect the precipit...

Embodiment 3

[0040] (1) Wash the kelp with sand removal, dry it, pulverize it, and pass it through a 40-mesh sieve to obtain the extracted raw materials;

[0041] (2) Add a citric acid solution with a pH value of 2 to the kelp raw material, add 30 times the weight of the dried kelp powder, extract at 120 ° C for 3 hours, filter, and separate the kelp residue to obtain an extract, and adjust the extract with potassium hydroxide pH to 6.5;

[0042] (3) ultrafiltration of the extract obtained in step (2) with a membrane with a molecular weight cut-off of 10,000 Daltons to collect the permeate part;

[0043] (4) vacuum-concentrating the ultrafiltration permeate to 1 / 5 of the original volume to obtain a concentrated solution;

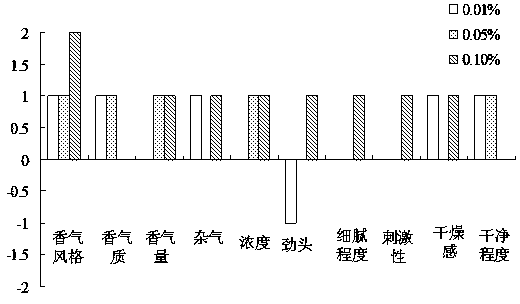

[0044] (5) Add ethanol to the concentrated solution, after mixing evenly, the final concentration of ethanol is 80% (v / v), stand at 4 °C for 12 hours, filter, remove the supernatant part, and precipitate the polysaccharide, and use ethanol and acetone. Dip 2-3 times; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com