Formula of novel docosahexaenoic acid (DHA) fat emulsion preparation and preparation method thereof

An emulsion and fat technology, which is applied in the direction of oil/fat/wax non-active ingredients, emulsion delivery, nervous system diseases, etc., can solve the problems of low content of active ingredients, low bioavailability, short shelf life, etc., to extend the shelf life , enhanced therapeutic effect, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: the ratio of DHA and diluent oil (the weight ratio of DHA: soybean oil is 1: 1)

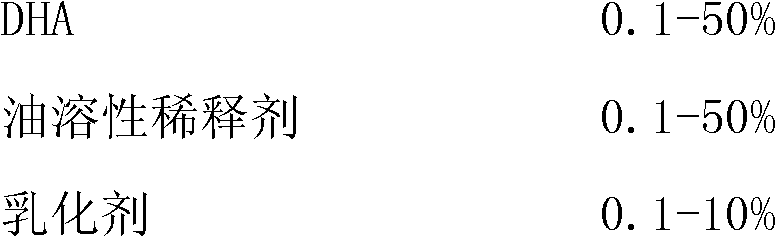

[0046] Prescription:

[0047]

[0048] Take 70.0g of DHA, 3.0g of vitamin E, 70.0g of refined soybean oil, add 12.5g of lecithin, heat and stir for about 10-20min to mix well. Another 700ml of water for injection was taken, and 22.0g of glycerin was added. Under the condition of nitrogen protection and stirring, the DHA phospholipid oil solution was added to the aqueous glycerin solution, and the total amount was adjusted to 1000ml. Homogenize 7-8 times with a high-pressure homogenizer, the homogenization pressure is 100MPa, until the particle size ranges from 180nm-300nm, adjust the pH to 7.0-8.0, filter, subpackage, inject nitrogen, and seal. Sterilize at 115°C for 30 minutes, and pack after passing the light inspection. Store below 25°C.

Embodiment 2

[0049] Embodiment 2: the ratio of DHA and diluent oil (DHA: the weight ratio of soybean oil is 0.03)

[0050] Prescription:

[0051]

[0052] Take 10.0g of DHA, 3.0g of vitamin E, 330.0g of refined soybean oil, add 12.5g of lecithin, heat and stir for about 10-20min to mix well. Another 700ml of water for injection was taken, and 22.0g of glycerin was added. Under the condition of nitrogen protection and stirring, the DHA phospholipid oil solution was added to the aqueous glycerin solution, and the total amount was adjusted to 1000ml. Homogenize 7-8 times with a high-pressure homogenizer, the homogenization pressure is 100MPa, until the particle size ranges from 180nm-300nm, adjust the pH to 7.0-8.0, filter, subpackage, inject nitrogen, and seal. Sterilize at 115°C for 30 minutes, and pack after passing the light inspection. Store below 25°C.

[0053](2) Inspection of the dosage range of diluent oil

[0054] Under the premise of ensuring that the ratio of DHA to the di...

Embodiment 3

[0055] Embodiment 3: the DHA fat emulsion preparation (diluted oil content 5%, weight content) of minimum soybean oil content

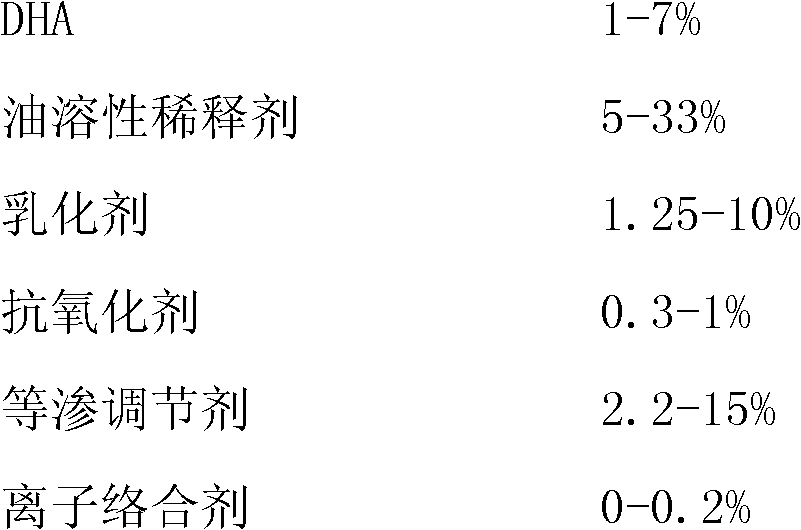

[0056] Prescription:

[0057]

[0058] Take 10.0g of DHA, 3.0g of vitamin E, 300.0g of refined soybean oil, add 12.5g of lecithin, heat and stir for about 10-20min to mix well. Another 600ml of water for injection was taken, and 22.0g of glycerol was added. Under the condition of nitrogen protection and stirring, the DHA phospholipid oil solution was added to the aqueous glycerin solution, and the total amount was adjusted to 1000ml. Homogenize 7-8 times with a high-pressure homogenizer, the homogenization pressure is 100MPa, until the particle size ranges from 180nm to 300nm, adjust the pH to 7.0-8.0, filter, sub-package, inject nitrogen, and seal. Sterilize at 115°C for 30 minutes, and pack after passing the light inspection. Store below 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com