Preparation method of nitrogen (N)-doped titanium dioxide (TiO2) microspheres

A technology of titanium dioxide and microspheres, which is applied in the field of preparation of TiO2 microspheres, can solve the problems of expensive raw materials and reduce raw material costs, and achieve the effects of low cost, good stability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

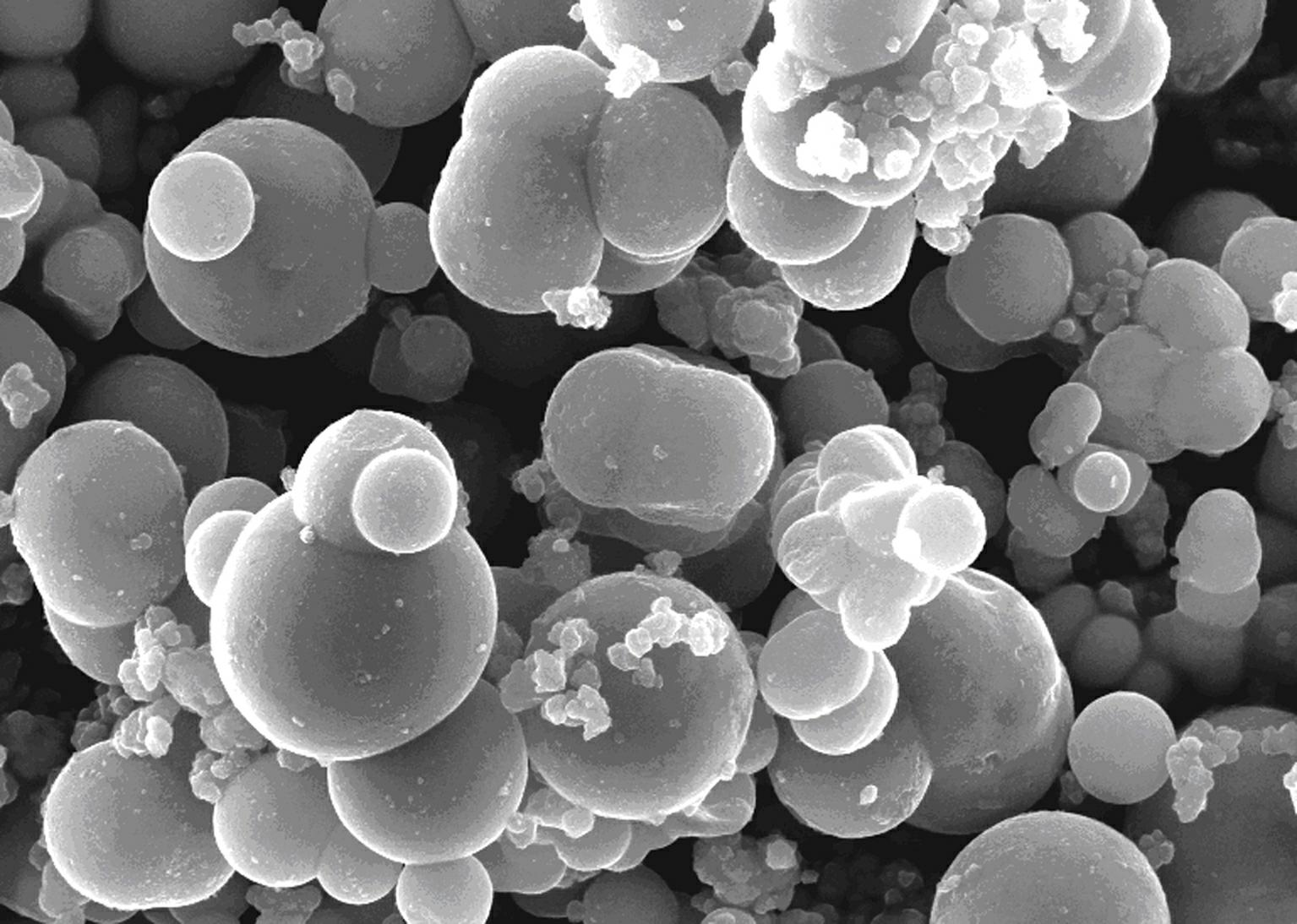

[0014] Embodiment 1 The mol ratio of hydrochloric acid and tetrabutyl titanate is respectively the TiO when 2:1 2 Microspheres

[0015] Pour the mixture of hydrochloric acid and tetrabutyl titanate with a molar ratio of 2:1 into the mixture of urea, ethanol and water and stir for 2-5 hours. The ratio of ethanol, water and urea is 130:0:1.7. The mixed solution is transferred to a pressure melting bomb and kept at 80-160° C. for 2-10 hours. The bottom precipitate was collected and calcined at 400° C. for 2 hours to obtain N-doped titanium dioxide microspheres. like figure 1 As shown, when M (HCl) :M (TBT) When it is 2:1, most of them are spherical, but there is still a considerable part of TiO 2 powder, and the dispersibility of microspheres is relatively poor.

Embodiment 2

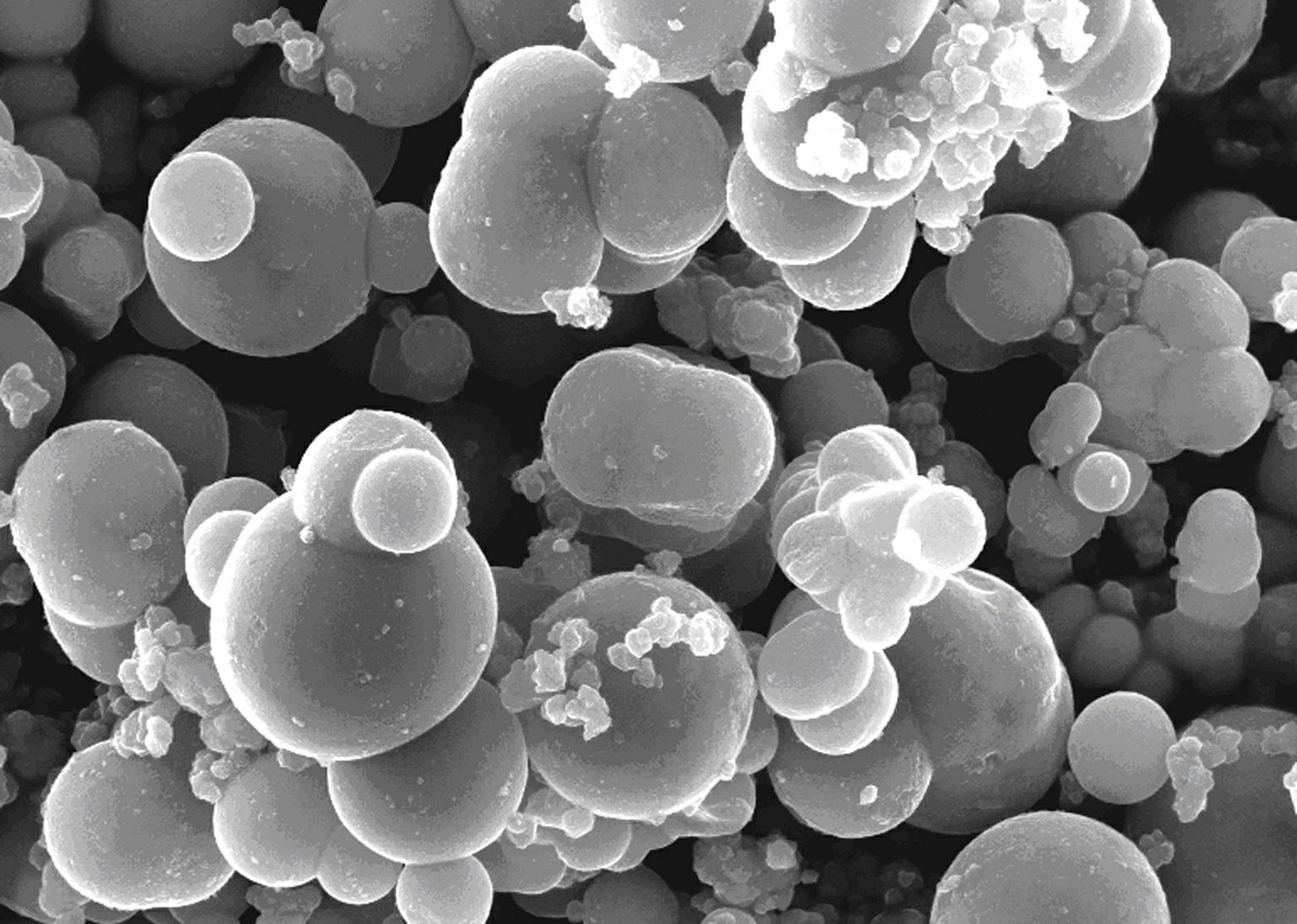

[0016] Embodiment 2 The mol ratio of hydrochloric acid and tetrabutyl titanate is respectively the TiO when 2.6:1 2 Microspheres

[0017] Pour the mixture of hydrochloric acid and tetrabutyl titanate with a molar ratio of 2.6:1 into the mixture of urea, ethanol and water and stir for 2-5 hours. The ratio of ethanol, water and urea is 130:0:1.7. The mixed solution is transferred to a pressure melting bomb and kept at 80-160° C. for 2-10 hours. The bottom precipitate was collected and calcined at 400° C. for 2 hours to obtain N-doped titanium dioxide microspheres. When M (HCl) :M (TBT) is 2.6:1 when ( figure 2 ) to get microspheres with good dispersion, but there is still a part of TiO 2 powder. Comparative Observation of Nitrogen-doped TiO by UV-Vis Absorption Spectroscopy 2 Changes in the spectral response of microspheres and P25 titanium dioxide powder (eg Image 6 Shown), it was found that the absorption intensity of nitrogen-doped microspheres exceeded P25 b...

Embodiment 3

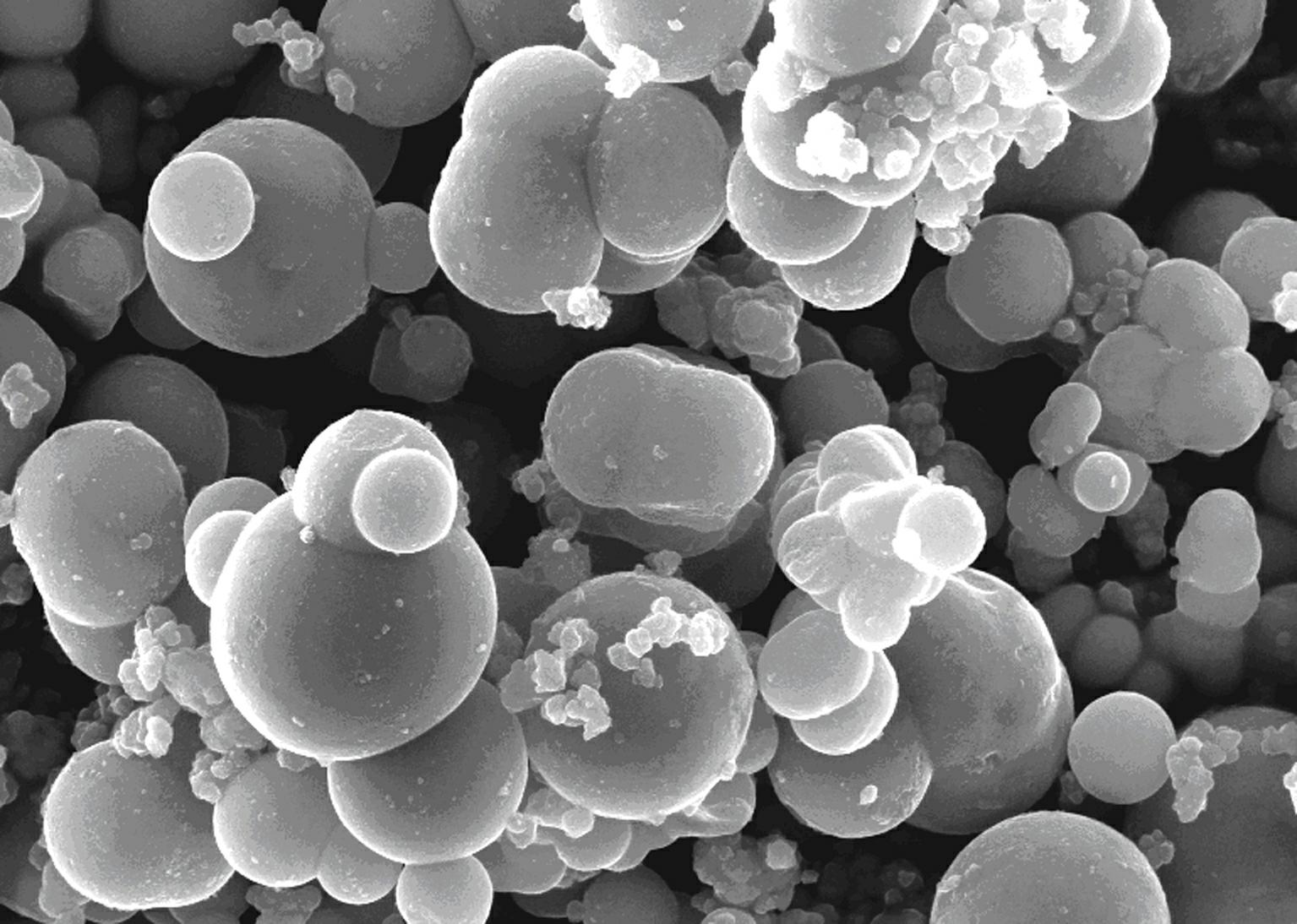

[0018] Embodiment 3 The mol ratio of hydrochloric acid and tetrabutyl titanate is respectively the TiO when 3.3:1 2 Microspheres

[0019] Pour the mixture of hydrochloric acid and tetrabutyl titanate with a molar ratio of 3.3:1 into the mixture of urea, ethanol and water and stir for 2-5 hours. The ratio of ethanol, water and urea is 130:0:1.7. The mixed solution is transferred to a pressure melting bomb and kept at 80-160° C. for 2-10 hours. The bottom precipitate was collected and calcined at 400° C. for 2 hours to obtain N-doped titanium dioxide microspheres. like image 3 Shown when M (HCl) :M (TBT) When it is 3.3:1, it basically forms a ball, and the particle size is relatively reduced, and the dispersion and uniformity are also improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com