Preparation method and application of ionic liquid bonded silica adsorbent

A technology of ionic liquid and bonded silica gel, which is applied in the field of analytical chemical sample pretreatment, can solve problems such as difficult repeated use, easy loss of ionic liquid, and poor mechanical strength of materials, so as to reduce analysis cost, maximize flexibility, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

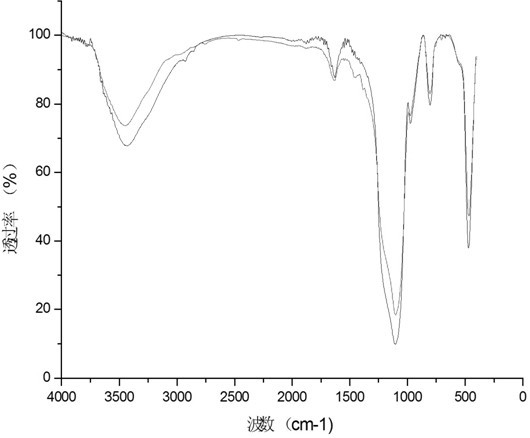

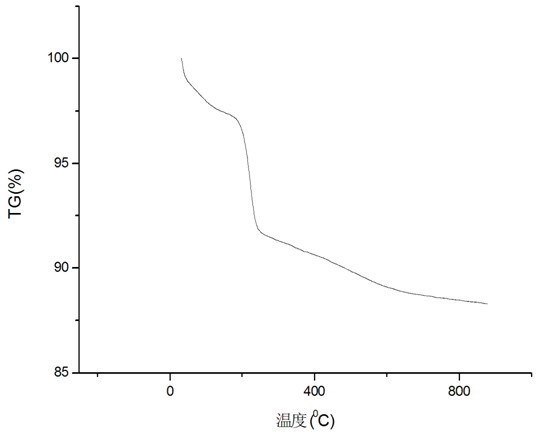

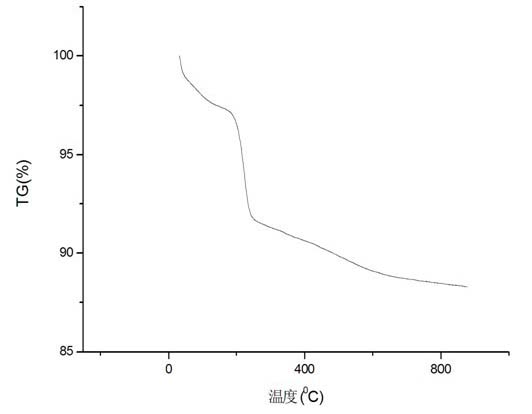

[0021] Take 5.0 g of activated silica gel in a 150 mL round-bottomed flask, add 5 mL of excess 3-aminopropyltriethoxysilane, 0.5 mL of triethylamine as a catalyst, and 60 mL of dry toluene as a reaction solvent, magnetically stir and reflux for 24 Hour. The reaction was stopped, and after the reaction was cooled, suction filtration was performed. Then the product was washed with 150 mL of toluene, and then washed with 300 mL of ethanol and 500 mL of ultrapure water. Dry at 50°C for 8 hours.

[0022] Weigh 2.0 g of the silanized silica gel product synthesized in the previous step, 3.0 g of 1,3-di-n-butylimidazolium hexafluorophosphate ionic liquid, and 30 mL of dried toluene as a solvent, stir mechanically, and reflux for 24 hours. After stopping the reaction, wait to cool to room temperature, and filter with suction. First wash twice with 100mL of methanol, then wash with 1:1 ethanol and 500mL of water, and finally wash with 150mL of methanol, and dry the washed product in ...

Embodiment 2

[0024] Take 4.0 g of activated silica gel in a 150 mL round bottom flask, add 4 mL of 3-aminopropyltriethoxysilane, 0.5 mL of triethylamine as a catalyst, and 50 mL of dry toluene as a reaction solvent, and magnetically stir and reflux for 24 hours . Stop the reaction, and filter with suction after the reaction is cooled. Then the product was washed with 150 mL of toluene, and then washed with 300 mL of ethanol and 500 mL of ultrapure water. Dry at 50°C for 8 hours.

[0025] Weigh 2.0 g of the silanized silica gel product synthesized in the previous step, 3.0 g of 1-hexyl-3-methylimidazolium hexafluorophosphate ionic liquid, and 30 mL of dried toluene as a solvent, stir mechanically, and reflux for 36 hours. After stopping the reaction, wait to cool to room temperature, and filter with suction. Wash twice with 100mL of methanol, then wash with 1:1 ethanol and 500mL of water, and finally wash with 120mL of methanol, and dry the washed product in an oven at 60°C for 8 hours t...

Embodiment 3

[0027] Take 3.0 g of activated silica gel in a 150 mL round bottom flask, add 3 mL of 3-aminopropyltriethoxysilane, 0.5 mL of triethylamine as a catalyst, and 30 mL of dry toluene as a reaction solvent, and magnetically stir and reflux for 24 hours . Stop the reaction, and filter with suction after the reaction is cooled. Then the product was washed with 100 mL of toluene, and then washed with 200 mL of ethanol and 500 mL of ultrapure water. Dry at 50°C for 8 hours.

[0028] Weigh 2.0g of the silanized silica gel product synthesized in the previous step, 3.0g of 1-butyl-3-methylimidazolium bromide ionic liquid, 30mL of dried toluene as solvent, stir mechanically, and reflux for 36 hours. After stopping the reaction, wait to cool to room temperature, and filter with suction. First wash twice with 100mL of methanol, then wash with 1:1 ethanol and 500mL of water, and finally wash with 150mL of methanol, and dry the washed product in an oven at 60°C for 8 hours to obtain an ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com