Preparation method and application of integral combustion catalyst for platinum-based honeycomb iron-chrome-aluminium wire mesh

A monolithic catalyst, iron-chromium-aluminum wire mesh technology, applied in combustion methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as inability to deposit platinum, achieve simple equipment, simple preparation methods, and excellent low temperature. The effect of the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

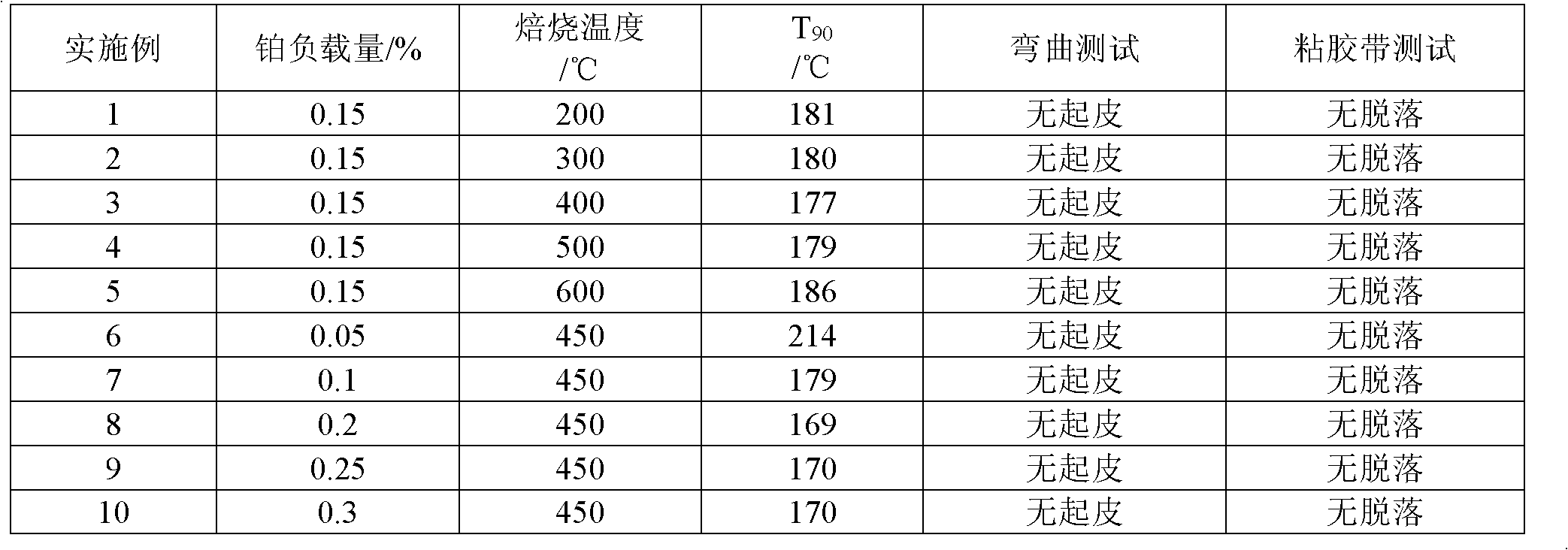

Examples

Embodiment 1

[0015] (1) Surface pretreatment of iron-chromium-aluminum wire mesh: first roll the iron-chromium-aluminum wire mesh into a loose honeycomb shape, ultrasonically degrease it in acetone for 10 minutes, rinse it with distilled water, and then place the iron-chromium-aluminum wire mesh in HNO 3 -HF mixed acid solution (HNO 3 :HF:H 2 The mass ratio of O is 26:5:69) soak in 40℃ for 2min, and finally take it out in distilled water and ultrasonic for 5min;

[0016] (2) Activation treatment of the iron-chromium-aluminum wire mesh: the iron-chromium-aluminum wire mesh after the surface pretreatment is made of 0.02g / L PdCl 2 Soak it in the activation solution prepared by mixing with 10ml / L of 36wt% concentrated hydrochloric acid at 60°C for 2min, take it out and rinse with distilled water;

[0017] (3) Electroless platinum plating: place the activated iron-chromium-aluminum wire mesh in a 0.124g / L H 2 PtCl 6 , 1.5g / L sodium hydroxide, 12g / L disodium ethylenediaminetetraacetate, 6g / L anhydrous ...

Embodiment 2

[0021] (1) Surface pretreatment of the iron-chromium-aluminum wire mesh: first roll the iron-chromium-aluminum wire mesh into a loose honeycomb shape, ultrasonically degrease it in acetone for 10 minutes, rinse it with distilled water, and then place the iron-chromium-aluminum wire mesh in HNO 3 -HF mixed acid solution (HNO 3 :HF:H 2 The mass ratio of O is 26:5:69) soak in 40℃ for 2min, and finally take it out in distilled water and ultrasonic for 5min;

[0022] (2) Activation treatment of the iron-chromium-aluminum wire mesh: the iron-chromium-aluminum wire mesh after the surface pretreatment is made of 0.02g / L PdCl 2 Soak in the activation solution prepared by mixing with 10ml / L of 36wt% concentrated hydrochloric acid at 60°C for 2min, take it out and rinse with distilled water;

[0023] (3) Electroless platinum plating: place the activated iron-chromium-aluminum wire mesh in a 0.131g / L H 2 PtCl 6 , 2g / L sodium hydroxide, 8g / L disodium ethylenediaminetetraacetate, 5g / L anhydrous et...

Embodiment 3

[0027] (1) Surface pretreatment of the iron-chromium-aluminum wire mesh: first roll the iron-chromium-aluminum wire mesh into a loose honeycomb shape, ultrasonically degrease it in acetone for 10 minutes, rinse it with distilled water, and then place the iron-chromium-aluminum wire mesh in HNO 3 -HF mixed acid solution (HNO 3 :HF:H 2 The mass ratio of O is 26:5:69) soaked in 40℃ for 2min, and finally taken out and ultrasonicated in distilled water for 5min;

[0028] (2) Activation treatment of the iron-chromium-aluminum wire mesh: the iron-chromium-aluminum wire mesh after the surface pretreatment is made of 0.02g / L PdCl 2 Soak in the activation solution prepared by mixing with 10ml / L of 36wt% concentrated hydrochloric acid at 60°C for 2min, take it out and rinse with distilled water;

[0029] (3) Electroless platinum plating: Place the activated iron-chromium-aluminum wire mesh in a 0.128g / L H 2 PtCl 6 , 1.2g / L sodium hydroxide, 15g / L disodium ethylenediaminetetraacetic acid, 6g / L a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com