Soldering flux and preparation method thereof

A flux and rosin technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of voids between the external electrode sheet and the piezoresistor electrode, pure tin solder and the external electrode sheet are not tinned, and silver-containing solder is melted Incomplete and other problems, to achieve the effect of high reliability of long-term electrical performance, easy to obtain, and good welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of flux among the present invention comprises the following steps:

[0031] a, rosin is ground into powder;

[0032] B, the rosin powder of step a is dissolved in the alkyl alcohol below 8 carbons;

[0033] c. Add deionized water and stir evenly.

[0034] Wherein, in the step b, the rosin powder is dissolved until no granular matter can be seen.

[0035] The preparation method of the flux that does not contain deionized water in the present invention may further comprise the steps:

[0036] a, rosin is ground into powder;

[0037] b. Dissolving the rosin powder in step a in an alkyl alcohol with 8 carbons or less.

[0038] Wherein, in the step b, the rosin powder is dissolved until no granular matter can be seen.

[0039] The flux of the present invention belongs to the resin flux, and its main component is rosin. Rosin mainly plays the role of isolating air and preventing metal surface oxidation, and can react with solder and the oxide film...

Embodiment 1

[0046] The preparation of embodiment 1 flux

[0047] Materials: hydrogenated rosin, methanol, deionized water.

[0048] Method: a, weigh 20g of hydrogenated rosin, grind it into powder;

[0049]B. Dissolve the rosin powder in step a in 10g of methanol, and stir evenly to dissolve the rosin until no granular matter can be seen;

[0050] c. Add 70 g of deionized water into the mixture obtained in step b, and stir evenly.

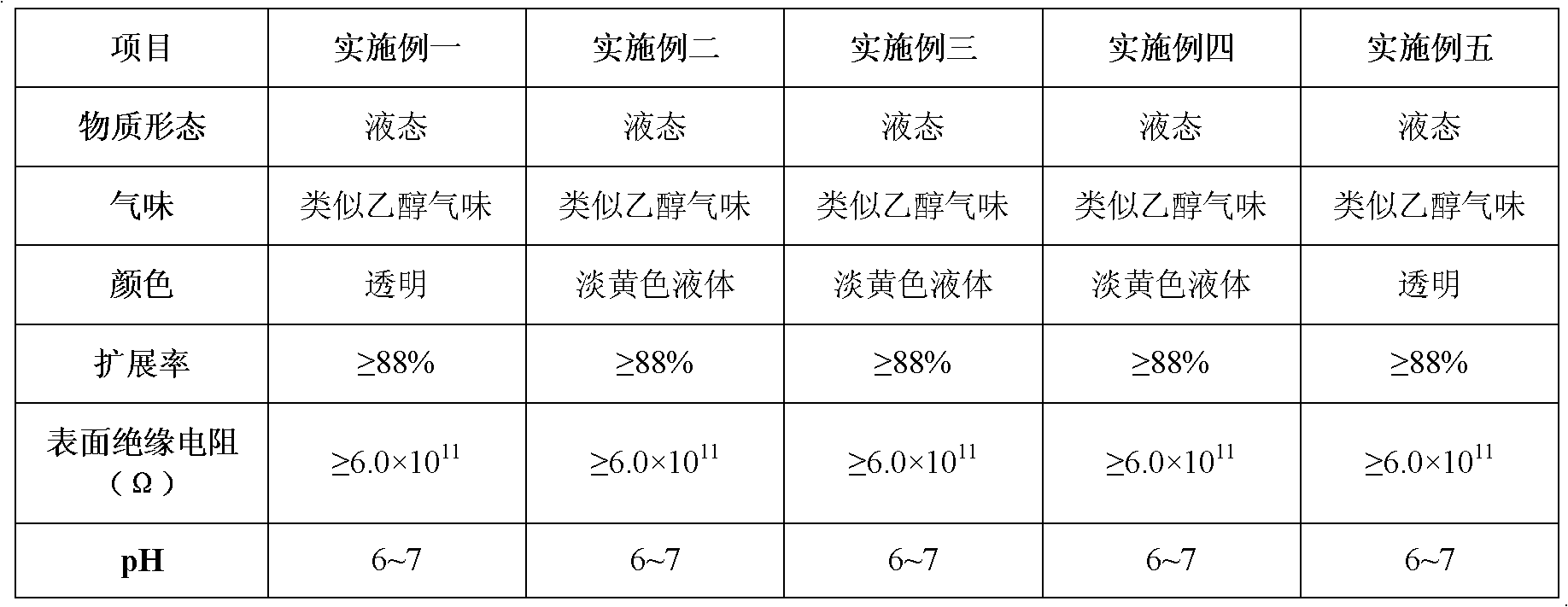

[0051] The physical and chemical parameters of the prepared flux are shown in Table 1.

Embodiment 2

[0052] The preparation of embodiment 2 welding flux

[0053] Materials: Masson rosin, ethanol.

[0054] Method: a. Weigh 10g of rosin massoniana and grind it into powder;

[0055] b. Dissolve the rosin powder in step a in 90 g of ethanol, stir evenly to dissolve the rosin until no granular matter can be seen.

[0056] The physical and chemical parameters of the prepared flux are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com