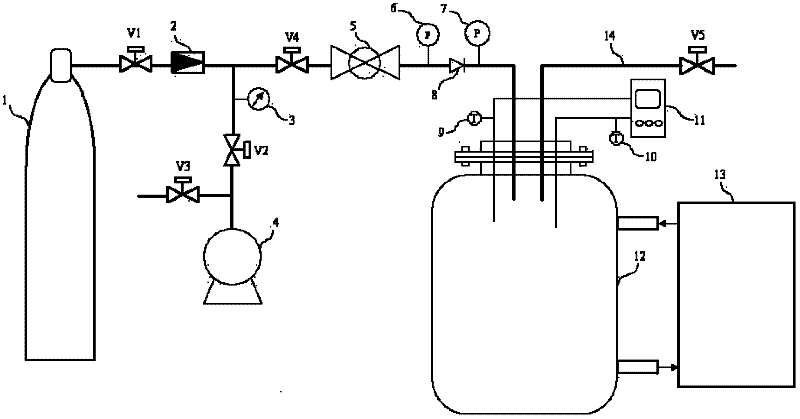

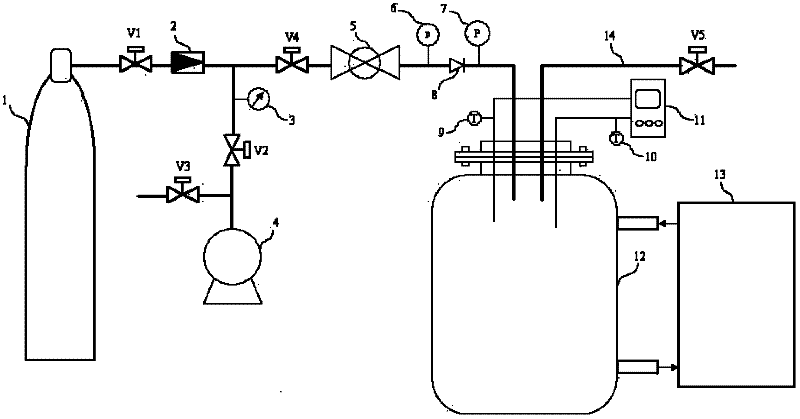

Adsorption-hydration reaction dual hydrogen-storing method and device

A hydration reaction, dual technology, applied in the container filling method, container discharge method, hydrogen technology and other directions, can solve the problems of slow gas storage rate, high hydrogen storage gas pressure, difficult to popularize, etc., to achieve convenient operation and improve storage. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

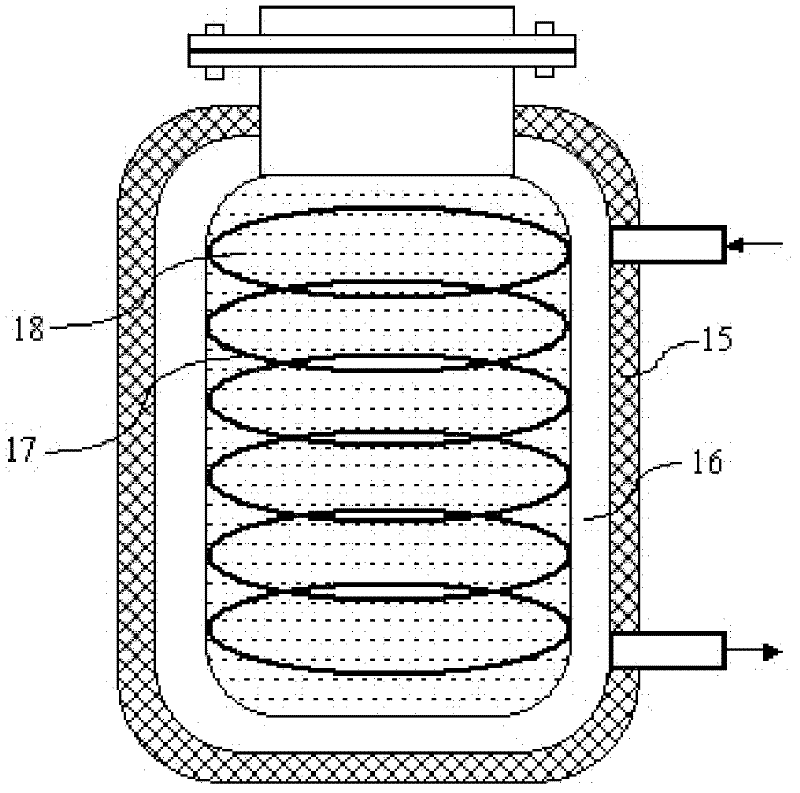

Image

Examples

Embodiment 1

[0024] First, the carbon nanotubes are soaked in a concentrated acid solution prepared with a mass ratio of concentrated sulfuric acid and concentrated nitric acid for 48 hours, and then taken out and dried under vacuum conditions. A tetrahydrofuran aqueous solution with a mass fraction of 21% was prepared (there was a slight excess of tetrahydrofuran in the reagent preparation due to the strong volatility of tetrahydrofuran). Fill the carbon nanotubes in the hydrogen storage tank, and evenly spray the tetrahydrofuran aqueous solution 3 times the mass of the carbon nanotubes on the carbon nanotubes. In order to avoid the volatilization of the tetrahydrofuran, this process should be carried out in a low temperature environment as much as possible. After sealing the hydrogen storage tank, place it for 24 hours, so that the carbon nanotubes can fully contact with the tetrahydrofuran aqueous solution. Then vacuumize the system, inject hydrogen into the hydrogen storage tank, and k...

Embodiment 2

[0027] Fill the carbon nanotubes after the concentrated acid immersion and drying treatment in the hydrogen storage tank, prepare a tetrabutylammonium bromide (TBAB) aqueous solution with a mass fraction of 32 wt%, and prepare the solution with an amount twice the mass of the carbon nanotubes The proportion is sprayed in the carbon nanotube system, the mixture is put into the hydrogen storage tank, and the hydrogen storage tank is sealed and left for 12 hours. Then vacuumize the system, and pass pressurized hydrogen into the storage tank to keep the pressure of the hydrogen storage tank at 30MPa. After the inflation is completed, set the ambient temperature in the hydrogen storage tank to -5°C, and the hydrogen storage process begins. When the pressure in the hydrogen storage tank does not change greatly, the hydrogen storage process basically ends.

[0028] The hydrogen release process is as in Example 1.

Embodiment 3

[0030] The concentrated acid soaked and cleaned carbon nanotube powder was vacuum-dried and put into a hydrogen storage tank, then a cycloacetone-water solution with a mass fraction of 14.77% was prepared, and an equivalent solution with the same mass as the carbon nanotube was evenly sprayed on the In the carbon nanotube powder in the hydrogen storage tank, then the hydrogen storage tank was sealed for 12 hours and vacuumized. Pass the pressurized hydrogen into the hydrogen storage tank, keep the pressure inside the hydrogen storage tank at 15MPa, turn on the external refrigeration cycle of the hydrogen storage tank, set the temperature at 0°C, and start storing hydrogen. When the pressure in the hydrogen storage tank does not change, the hydrogen storage process ends.

[0031] The hydrogen release process is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com