Method for preparation of Cu2O and Au/Cu2O core-shell heterostructure nano cube through thermal oxidation

A nano-cube and heterojunction technology, applied in the field of nano-materials, can solve the problems of difficult removal and impurities with nanoparticles, and achieve the effects of low production cost, controllable shape and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

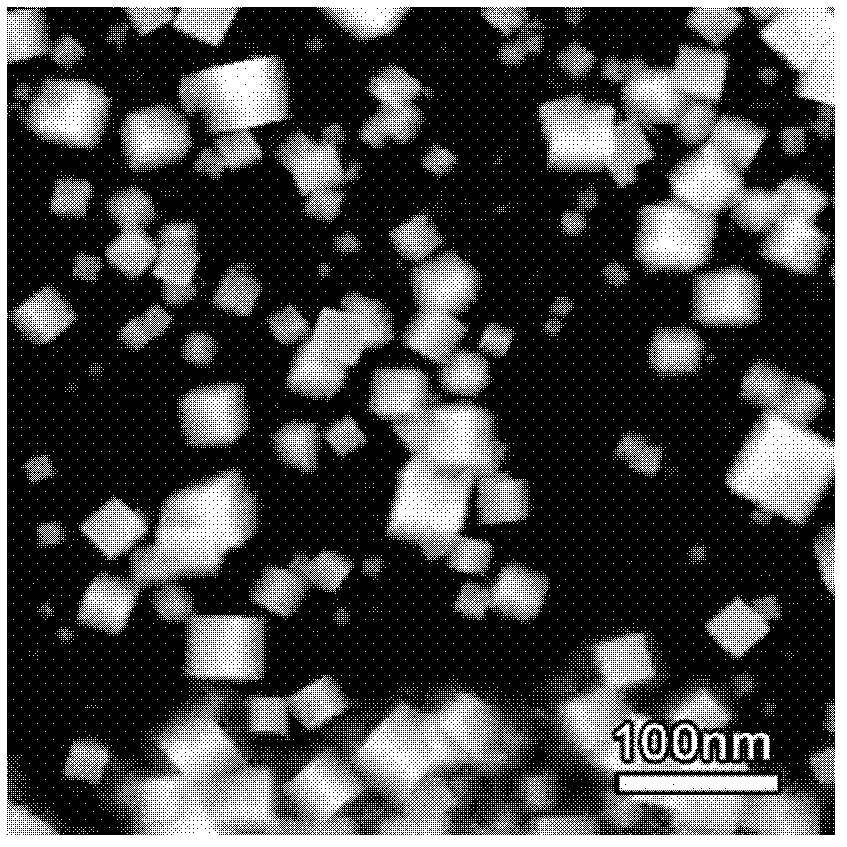

[0021] Example 1, Cu 2 Preparation of O nanocubes

[0022] 1) HAuCl 4 ·3H 2 O and n-tetraoctylammonium bromide (TOAB) were dissolved in deionized water and toluene respectively, stirred evenly, and prepared into 0.03M HAuCl 4 aqueous solution and 0.15M TOAB in toluene.

[0023] 2) Take 6 mL each of the above solutions, and add HAuCl 4 The aqueous solution was added to the toluene solution of TOAB, and stirred at room temperature for 10 minutes, the aqueous solution changed from yellow to colorless, and the toluene solution turned orange.

[0024] 3) Take newly prepared 0.26M NaBH 4 6 mL of aqueous solution was added dropwise to the reaction mixture obtained in step 2) within 30 min, and stirred rapidly for 30 min.

[0025] 4) the organic phase in the mixed solution obtained in step 3) is separated, and the 2 SO 4 The solution was washed once, then washed five times with distilled water, and finally with MgSO 4 The organic phase is dried and filtered through filter pap...

Embodiment 2

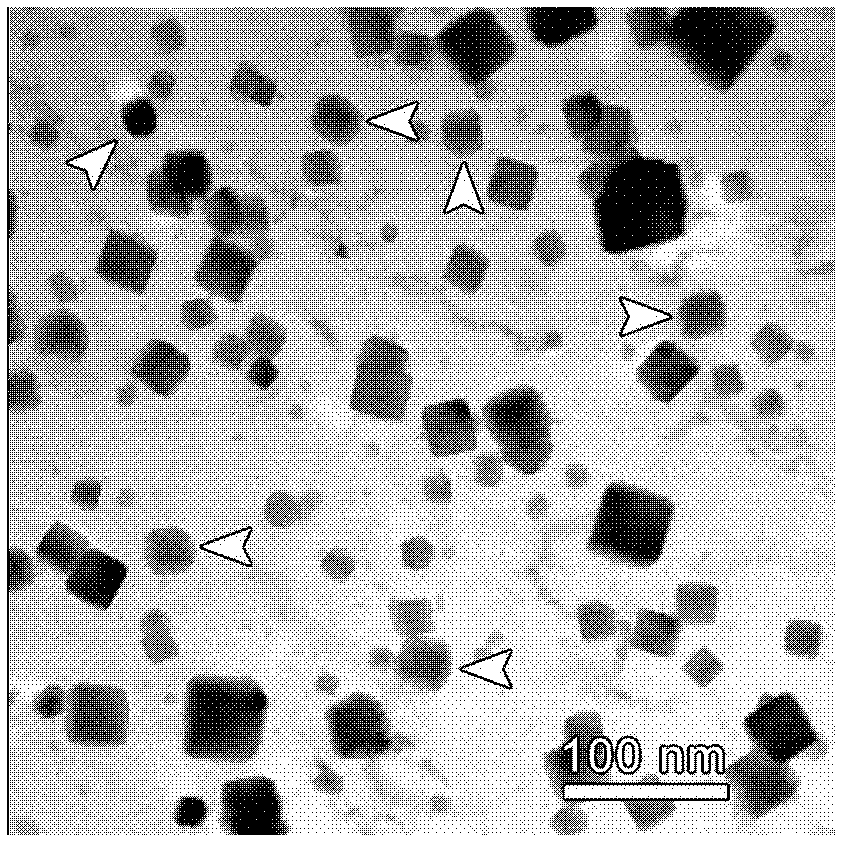

[0029] Embodiment 2, Au / Cu 2 Preparation of O core-shell heterojunction nanocubes:

[0030] 1) The preparation of Au nanoparticles is the same as steps 1)-4) in Example 1.

[0031] 2) Disperse the Au nanoparticles coated with TOAB stabilizer obtained in step 1) onto the copper mesh microgrid coated with carbon film, wherein the density of Au nanoparticles on the copper mesh is ≥2500 / μm 2, and then place the microgrid in a holding furnace, heat it up to 100°C at a heating rate of 1°C / s, and hold it for 30min. It was found that the particle size of Au nanoparticles increased from 5.2nm to 6nm, and no other substances were found to be formed.

[0032] 3) The heating temperature in step 2) was raised to 200° C. and kept for 30 minutes. It was found that the particle size of Au nanoparticles increased to 15 nm, and no other substances were found to be formed.

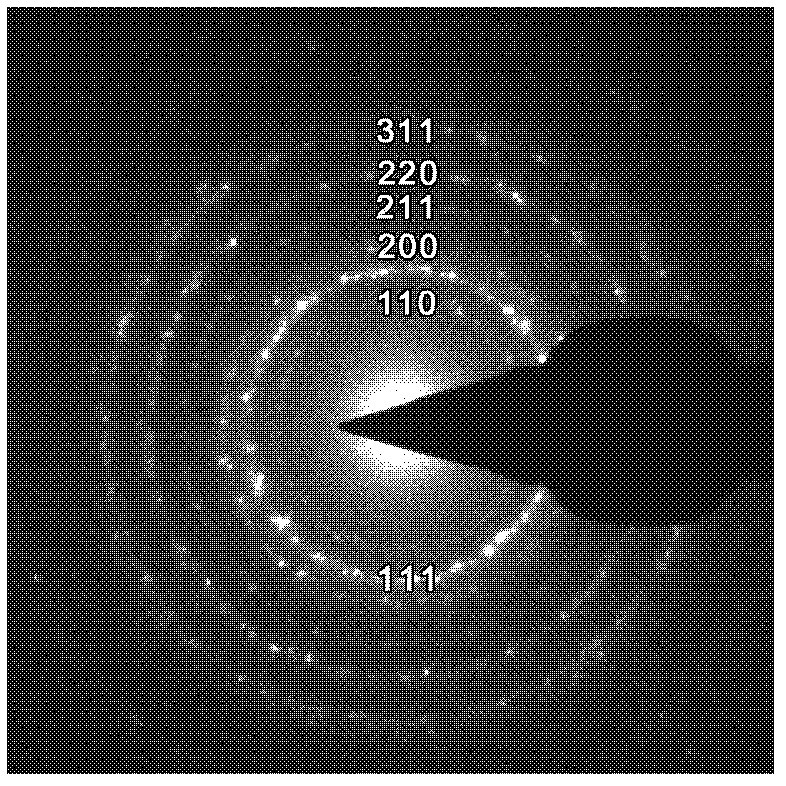

[0033] 4) Raise the heating temperature in step 3) to 300°C and keep it warm for 30 minutes to obtain Au / Cu 2 O core-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com