Method for preparing seepy material by using city sludge and sugar filter mud

A technology of urban sludge and permeable materials, applied in the fields of sewage treatment and resources and environment, can solve the problem of high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

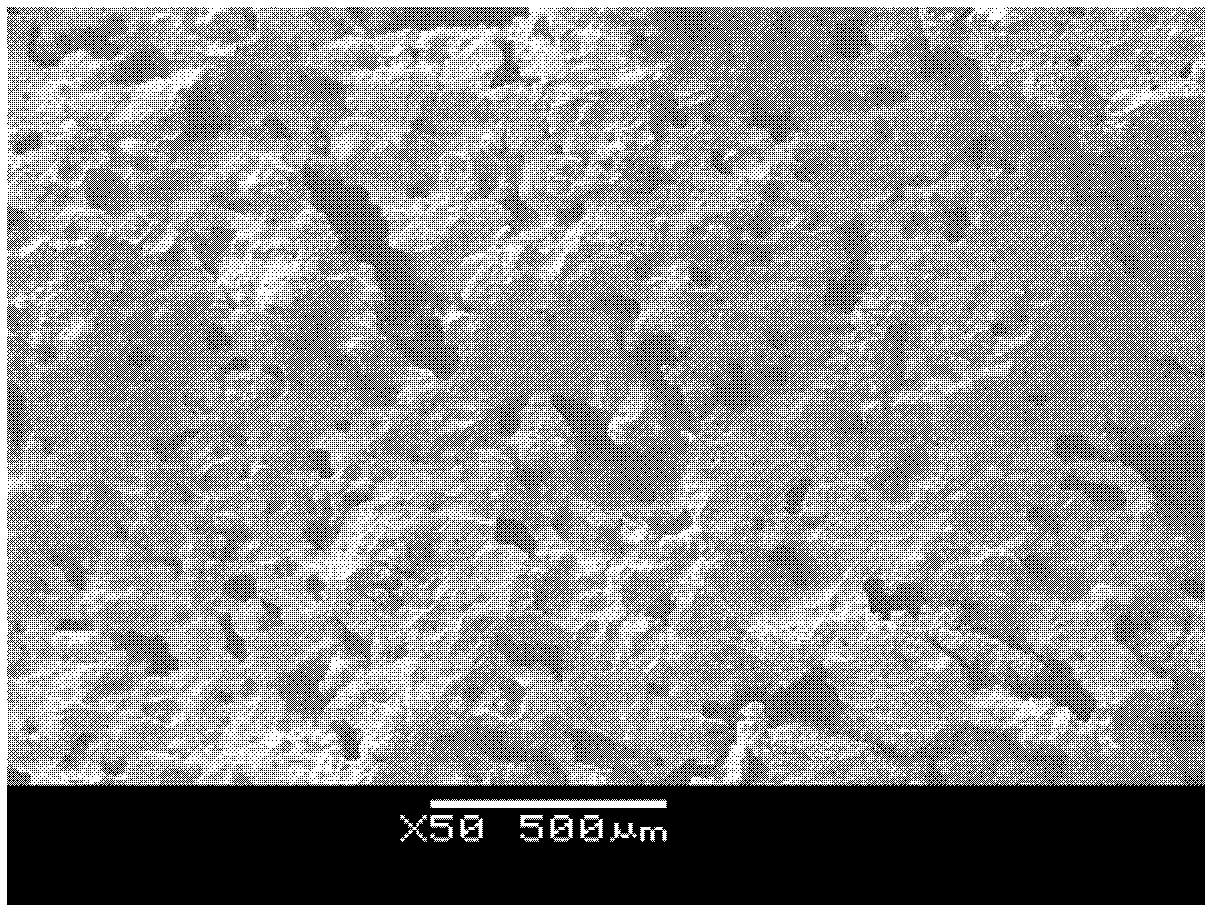

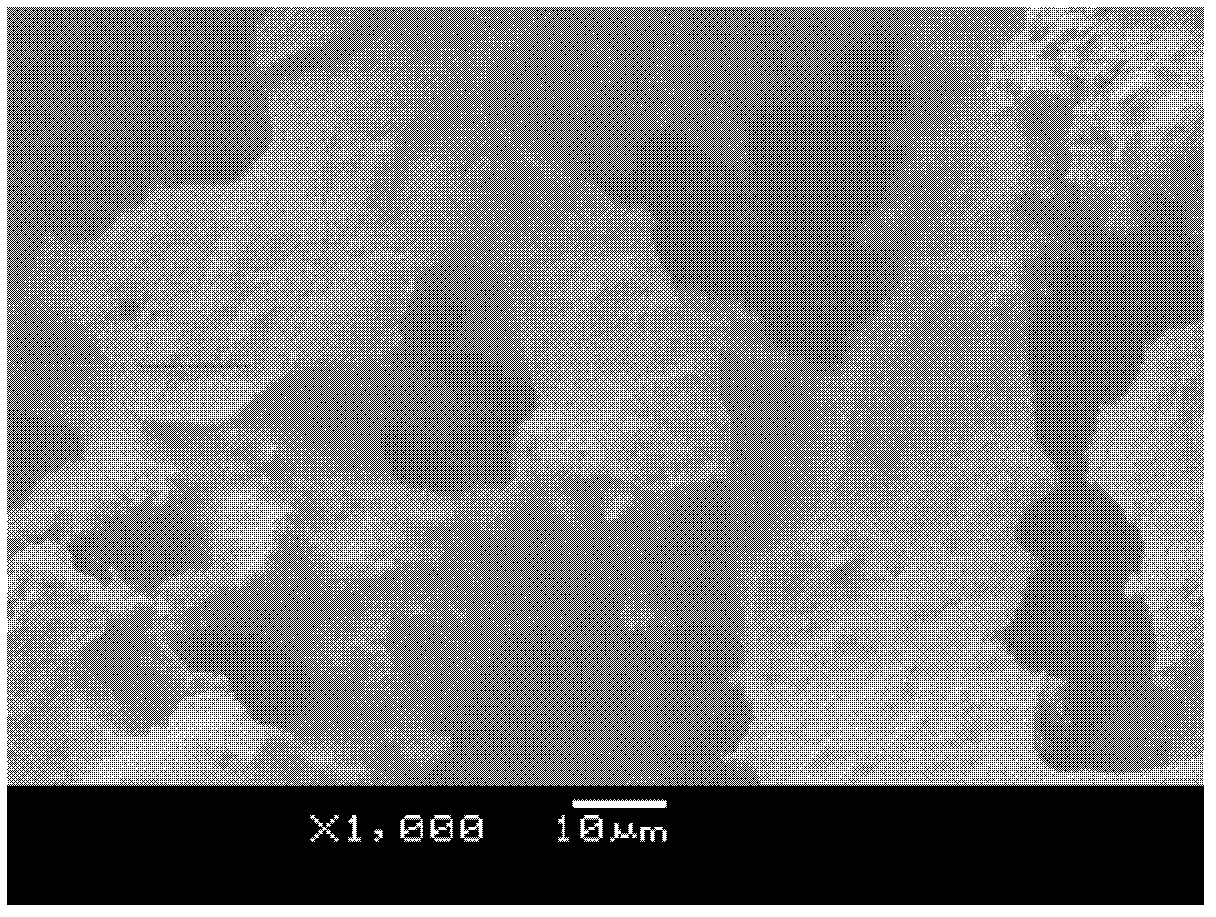

Image

Examples

Embodiment 1

[0021] a. Raw material preparation: After dehydration treatment of urban sludge and sugar filter mud, drying and drying to make the relative moisture content ≤ 13%; after crushing fly ash, take 160-mesh sieve for feeding, and sugar filter mud, water koji Willow clay is ground by a ball mill and passed through a 100-mesh sieve, and the sieve material is taken; the particle size of the municipal sludge is controlled to 20-40 mesh after crushing, and the waste ceramics are crushed and passed through a 20-mesh sieve; waste glass is crushed and ground into glass powder Pass through 160 mesh sieve;

[0022] b. Billet: according to the mass percentage of permeable material formula: 14% for sugar filter mud, 4% for municipal sludge, 20% for fly ash, 35% for clay, 23% for waste ceramics, and 4% for glass powder Weigh the prepared various raw materials and mix them to form a batch and add water, wherein the amount of water added is 10% of the absolute dry mass of the batch. After mixing...

Embodiment 2

[0027] According to the mass percentage of the permeable material formula in the billet making step: sugar filter mud is 15%, municipal sludge is 5%, fly ash is 20%, clay is 38%, waste ceramics is 17%, and glass powder is 5%. Get the prepared various raw materials and mix to form the batch and add water, wherein the amount of water added is 11% of the absolute dry mass of the batch,

[0028] All the other processing steps are identical with embodiment 1.

Embodiment 3

[0030] According to the mass percentage of the permeable material formula in the billet making step: sugar filter mud is 15%, municipal sludge is 6%, fly ash is 23%, clay is 36%, waste ceramics is 15%, and glass powder is 5%. Mix the prepared raw materials to form a batch and add water, wherein the amount of water added is 12% of the absolute dry mass of the batch. After mixing, stir for 3 hours, granulate it, and stale for 24 hours; Molding, the molding pressure is 15 MPa; then, put it into a drying oven for drying, the drying temperature is 105°C, and the drying time is 6 hours to obtain a dry billet.

[0031] All the other processing steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com