High-nitrogen composite fertilizer and preparation method thereof

A technology of high nitrogen compound fertilizer and monoammonium phosphate, applied in the field of high nitrogen compound fertilizer and its preparation, can solve the problems of poor crop absorption rate, soil pollution, crop yield reduction, etc., achieves soil damage mitigation, simple preparation method, and provides Anti-lodging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: high-nitrogen compound fertilizer, the parts by weight of its raw materials are: potassium chloride 125kg, monoammonium phosphate 250kg, urea 400kg, ammonium bicarbonate 25kg, ammonium sulfate 150kg and calcium powder 50kg.

[0014] The preparation method of high-nitrogen compound fertilizer comprises the following steps:

[0015] (1) Weigh each raw material according to the weight of the constituent raw materials, then add them into the conveyor together and mix them uniformly, then crush and mix them, and finally add them to the granulator for granulation;

[0016] (2) The granulated granules are sequentially dried, cooled, secondary sieved and coated, and finally packaged to obtain the finished product.

Embodiment 2

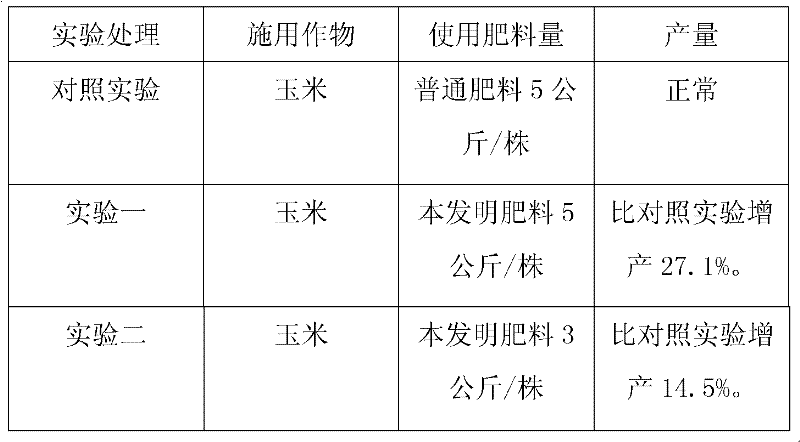

[0017] Embodiment 2: the use effect data comparison of high-nitrogen compound fertilizer:

[0018] Bio-organic fertilizer in 100 mu of orchard comparative test results (average): 134.6 kg per mu of cultivated land, an increase of 12.36%, and 118.2 kg per mu of mountainous land, an increase of 19.7%.

[0019] Use the plant disease resistance of the present invention's high-nitrogen compound fertilizer and the investigation form of fruit character:

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com