Preparation method for chromatographic grade N,N-dimethyl formamide

A dimethylformamide, chromatographic-grade technology, applied in the separation/purification of carboxylic acid amides, organic chemistry, etc., can solve the problem of high ultraviolet absorbance, and achieve the effects of high product purity, separation of impurities, and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of chromatographic grade N, N-dimethylformamide, the steps are as follows:

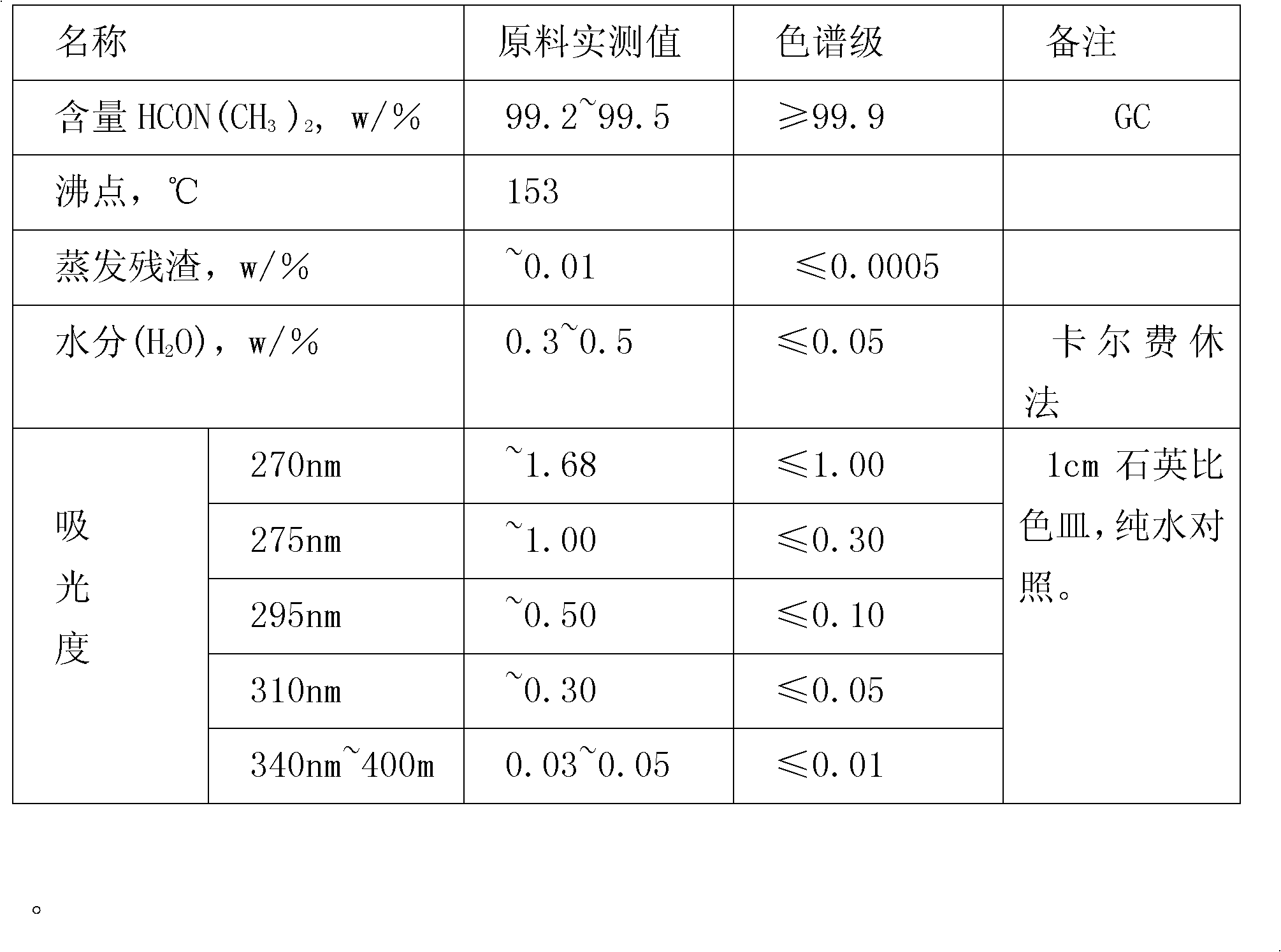

[0021] (1) The raw material N,N-dimethylformamide (content is about 99.5%) is passed through a calcium hydride adsorption column with a particle size of 5mm to 10mm, the column volume is 4 / 5 of the column length, and the flow rate is about 50mL / min, N, N-dimethylformamide raw material is in full contact with calcium hydride, absorbs impurities such as moisture in it, and waits for the adsorption effluent to pass the inspection (that is, the indicators of the effluent are close to the technical index requirements of the chromatographic level, and the specific technical index requirements See table 1.) and enter the next step operation;

[0022] (2) Put the adsorption liquid in step (1) into a still, add 5% aluminum oxide (weight ratio) in the still, and pre-fire at 500-600° C. for about 1 hour. Distill under reduced pressure at a pressure of 5-10mmHg to further dehydrate a...

Embodiment 2

[0025] A preparation method of chromatographic grade N, N-dimethylformamide, the steps are as follows:

[0026] (1) The raw material N,N-dimethylformamide (content is about 99.5%) is passed through a calcium hydride adsorption column with a particle size of 10 mm to 15 mm. The amount of calcium hydride packed into the column is 4 / 5 of the column length, and the flow rate is about 140mL / min, N,N-dimethylformamide raw material is fully contacted with calcium hydride, absorbs impurities such as moisture in it, and waits for the adsorption effluent to pass the inspection (that is, the indicators of the effluent are close to the technical indicators of the chromatographic level, and the specific technology The index requirements are shown in Table 1.) and enter the next step;

[0027] (2) Pour the above-mentioned adsorption effluent into a still, add about 20% alumina (weight ratio) in the still, pre-burn at 500-600°C for about 2 hours, and distill under reduced pressure under a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com