Preparation method for high-purity ionic liquid

An ionic liquid and high-purity technology, applied in the field of high-purity ionic liquid preparation, can solve the problems of lack of method specificity, high product impurity content and high synthesis cost, and achieve the effects of simple process, good product quality and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

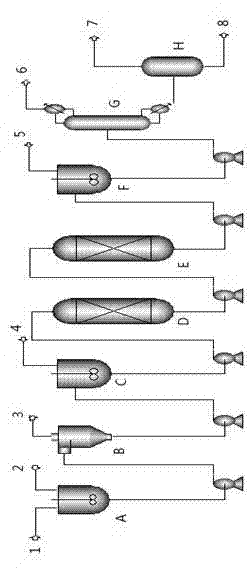

Method used

Image

Examples

Embodiment 1

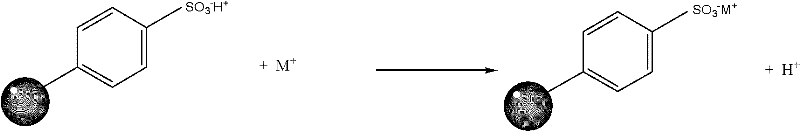

[0041] The preparation of embodiment 1,1-methyl-3-butylimidazole acetic acid ionic liquid

[0042] Step 1, metathesis reaction synthesis 1-methyl-3-butyl imidazole base

[0043] Dissolve 214.2g of 1-methyl-3-butylimidazolium chloride (0.9mol) in 300g of absolute ethanol, place in a 1L reactor, dissolve 50.4g of potassium hydroxide (0.9mol) in 250g of anhydrous Slowly add ethanol to the reactor, and react at room temperature for 12 hours under full stirring, and filter to remove potassium chloride precipitate after the reaction, to obtain a 1-methyl-3-butylimidazole alkali solution with a mass content of about 28% , The yield (based on 1-methyl-3-butylimidazole base) is about 95%.

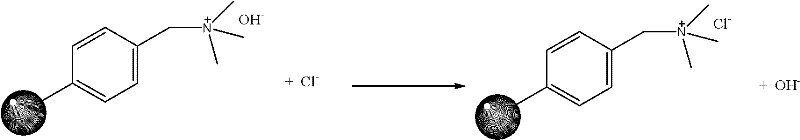

[0044] Step 2, ion exchange to remove chloride ions

[0045] Pack 201×7 strong base anion exchange resin (chlorine type) in a glass column with a size of Φ16×500mm, and the filling height is 450mm. First wash the resin with 100mL deionized water, then rinse with 100mL 4% NaOH, then rinse with 150...

Embodiment 2~3

[0055] Change step 1 potassium hydroxide consumption, other conditions are identical with embodiment 1, and the results are shown in Table 1

Embodiment 4~5

[0057] Change the concentration of hydroxide in step 2, other conditions are identical with embodiment 1, the results are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com