Method for preparing flammable gas by using peach tree branches of different particle diameters

A peach tree and gas technology, applied in the field of biomass energy utilization, can solve the problems of poor gas quality, difficult ignition, unstable gas production, etc., and achieve the effect of realizing resource utilization and overcoming ignition difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

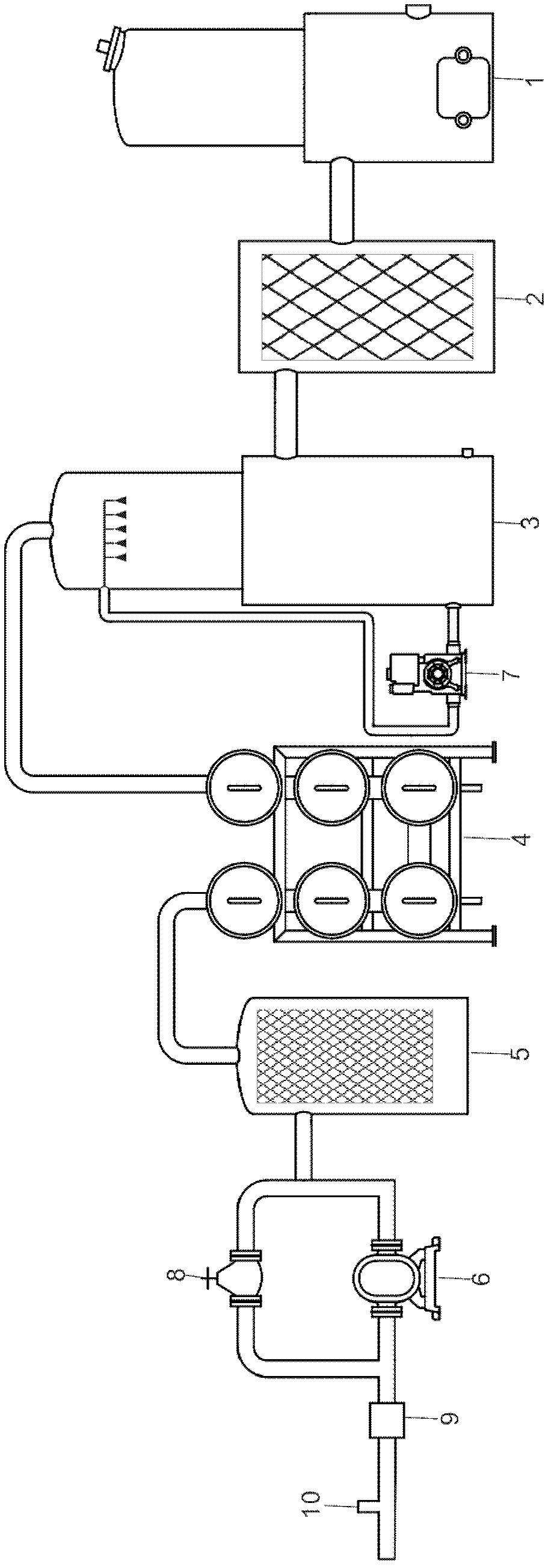

Method used

Image

Examples

Embodiment 1

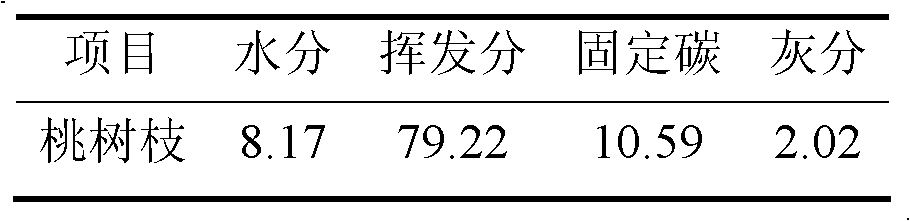

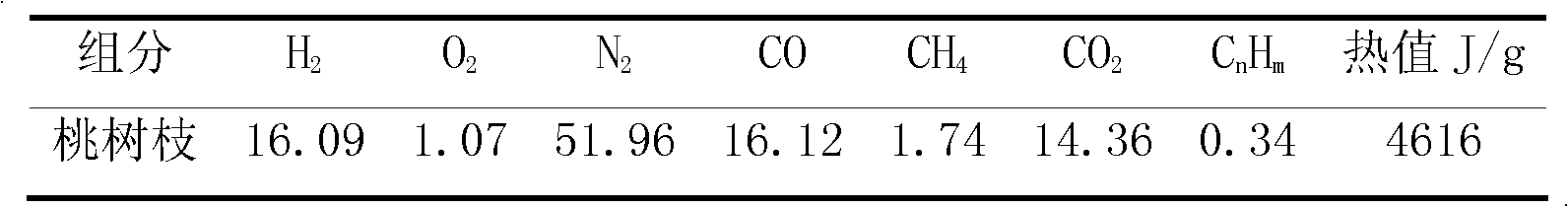

[0023] ① Raw material preparation: collect the discarded peach branches (diameter less than 1cm) after pruning, and spread them on the open space to dry naturally, so that the moisture content is less than 15%.

[0024] ② Cutting: Cut it into strips with a length of 2 to 3 cm with a hay cutter.

[0025] ③Gasifier pre-feeding: open the soot removal door of the gasifier, fill the lower part of the gasifier with an appropriate amount of lump charcoal; then add a little lump charcoal from the gasifier feed port, and add it to the limit below the throat nozzle; After adding charcoal, add granular fuel to the gasifier. The granular fuel should be added to the lower edge of the slope in the furnace; after adding granular fuel, add a small amount of easy-to-burn materials for ignition when lighting the furnace.

[0026] ④ Ignition preparation: Check whether the drive shaft of the Roots blower can be turned by hand. If not, inject an appropriate amount of industrial alcohol from the cl...

Embodiment 2

[0032] ① Raw material preparation: collect discarded peach branches (1-2 cm in diameter) after pruning, and spread them on the open space to dry naturally, so that the moisture content is less than 15%.

[0033] ② Cutting: Cut it into strips with a length of 2 to 3 cm with a hay cutter.

[0034] ③Gasifier pre-feeding: open the soot removal door of the gasifier, fill the lower part of the gasifier with an appropriate amount of lump charcoal; then add a little lump charcoal from the gasifier feed port, and add it to the limit below the throat nozzle; After adding charcoal, add granular fuel to the gasifier. The granular fuel should be added to the lower edge of the slope in the furnace; after adding granular fuel, add a small amount of easy-to-burn materials for ignition when lighting the furnace.

[0035] ④ Ignition preparation: Check whether the drive shaft of the Roots blower can be turned by hand. If not, inject an appropriate amount of industrial alcohol from the cleaning p...

Embodiment 3

[0041] ① Raw material preparation: collect the discarded peach branches (2-4cm in diameter) after pruning, and spread them on the open space to dry naturally, so that the water content is less than 15%.

[0042] ② Cutting: Cut it into strips with a length of 2 to 3 cm with a hay cutter.

[0043] ③Gasifier pre-feeding: open the soot removal door of the gasifier, fill the lower part of the gasifier with an appropriate amount of lump charcoal; then add a little lump charcoal from the gasifier feed port, and add it to the limit below the throat nozzle; After adding charcoal, add granular fuel to the gasifier. The granular fuel should be added to the lower edge of the slope in the furnace; after adding granular fuel, add a small amount of easy-to-burn materials for ignition when lighting the furnace.

[0044] ④ Ignition preparation: Check whether the drive shaft of the Roots blower can be turned by hand. If not, inject an appropriate amount of industrial alcohol from the cleaning p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com