Method for extracting oil and procyanidin from grape seeds

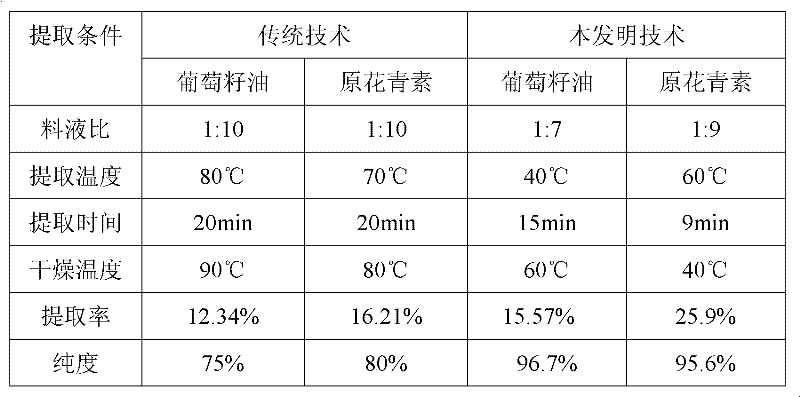

A proanthocyanidin and oil extraction technology, which is applied in the direction of oil/fat production, fat production, anti-toxic agents, etc., can solve the problems of relatively high operating conditions, solvent residues, and complex production equipment, so as to improve extraction efficiency, reduce extraction temperature, The effect of reducing the extraction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

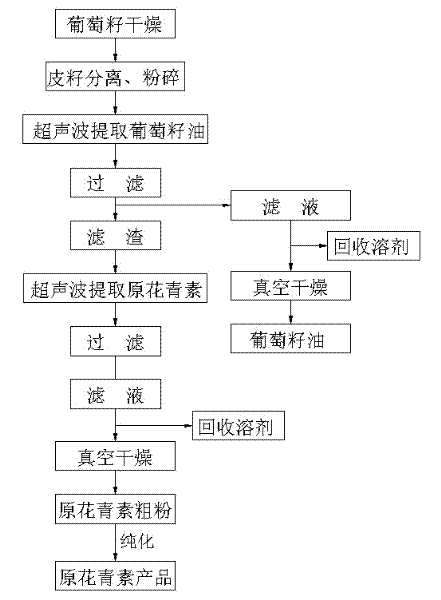

Method used

Image

Examples

Embodiment 1

[0021] 1) Preparation of grape seeds: the grape skin pomace after recovering the wine liquid is dried to remove the remaining moisture until the water content is less than 2%, and then the grape skins are separated from the grape seeds to obtain the grape seeds;

[0022] 2) Pulverization: pulverize the air-dried grape seeds to 80 meshes and set aside.

[0023] 3) Ultrasonic extraction of grape seed oil: according to the solubility of grape seed oil and proanthocyanidins, first extract grape seed oil from grape seeds, weigh 2 g of 80-mesh grape seed powder after crushing, add 14 ml of petroleum ether with a volume fraction ≥ 99.5%, Place it in an ultrasonic extractor for extraction, the extraction temperature is 60°C, and the extraction time is 15 minutes. After the extraction is completed, filter the extract to obtain the filtrate and filter residue, concentrate the filtrate and recover the solvent, and use the recovered solvent to extract the filter residue again. The extract...

Embodiment 2-3

[0027] Extraction of grape seed oil: on the basis of implementation case 1, change the volume fraction of extraction solvent, extraction temperature (°C), extraction time (min), extraction times, solid-liquid ratio (g / ml), particle size of grape seed raw material Size and other process parameters, the specific implementation parameters are shown in the following table:

[0028]

[0029] In the above-mentioned Examples 2-3, the parameters for extracting proanthocyanidins from the filter residue after extracting grape seed oil are: volume fraction of extraction solvent, extraction temperature (°C), extraction time (min), extraction times, solid-liquid ratio (g / ml), the specific implementation parameters are shown in the following table:

[0030]

[0031] The purification of proanthocyanidins was the same as in Case 1.

Embodiment 4-5

[0033] Extraction of grape seed oil: On the basis of the implementation of Case 2-3, other extraction conditions remain unchanged, only the volume fraction of the extraction solvent and the particle size of the grape seed raw material are changed, and the specific implementation parameters are as follows:

[0034]

[0035] Extraction of proanthocyanidins: On the basis of the implementation of Case 2-3, other extraction conditions are fixed, only the volume fraction of the extraction solvent and the particle size of the grape seed raw material are changed. The specific implementation parameters are as follows:

[0036]

[0037] The purification of proanthocyanidins is the same as in Example 1.

[0038] In the above examples, the purification of proanthocyanidins can be carried out using existing techniques.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com