Method for preparing soybean curb residue dietary fiber edible paper

A technology of dietary fiber and bean curd residue, applied in non-fiber pulp addition, fiber raw material processing, paper and other directions, can solve the problems of limited application scope and low wet strength of paper, achieve wide application scope, realize reuse and resource utilization, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

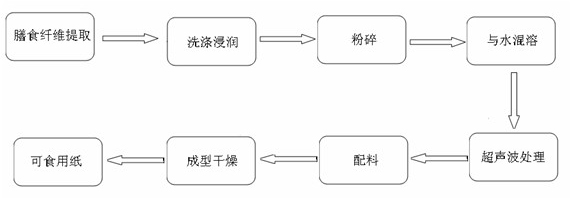

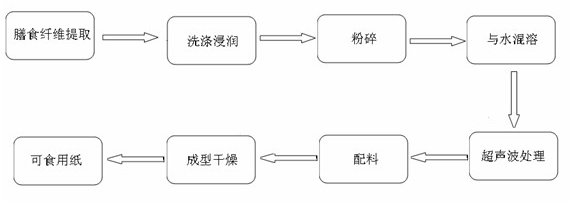

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation method of this bean curd dregs dietary fiber edible paper, concrete operations are as follows:

[0020] (1) Dried bean curd dregs are dried and degreased, then dried, and dietary fiber is extracted from bean curd dregs by enzymatic method

[0021] Dry the bean dregs at 100°C and pass through a 120-mesh sieve for degreasing treatment (the degreasing refers to soaking the bean curd residues with ether 8 times the volume of the bean curd residues for 8 hours), then wash with water to remove the organic solvent, and then dry at 80°C; Add pure water to the dried bean curd residue according to the mass ratio of liquid to material 25:1, adjust the pH of the solution to 6, add papain with a mass percentage of 4%, put it in a water bath at 50°C, and use an ultrasonic power of 150 W for 60 minutes of synergistic enzymolysis; Adjust the pH of the solution to 5, add 1% glucoamylase by mass, bathe in a water bath at 50°C, use an ultrasonic power of 200 ...

Embodiment 2

[0027] Embodiment 2: the preparation method of this bean curd dregs dietary fiber edible paper, concrete operations are as follows:

[0028] (1) Dried bean curd dregs are dried and degreased, then dried, and dietary fiber is extracted from bean curd dregs by enzymatic method

[0029] Dry the bean dregs at 100°C and pass through a 100-mesh sieve for degreasing treatment (the degreasing refers to soaking bean curd residues in ethanol with 7 times the volume of bean curd residues for 5 hours), then washing with water to remove the organic solvent, and then drying at 100°C; The dried bean curd dregs was added with pure water according to the mass ratio of liquid to material 25:1, and the solution was adjusted to pH = 6, and papain with a mass percentage of 4% was added, in a water bath at 50°C, with an ultrasonic power of 150 W, and synergistic enzyme Decompose for 60 minutes; then adjust pH=5, add 1% glucoamylase by mass, bathe in 50°C water, ultrasonic power 200 W, and co-enzyme...

Embodiment 3

[0035] Embodiment 3: the preparation method of this bean curd dregs dietary fiber edible paper, concrete operations are as follows:

[0036] (1) Dried bean curd dregs are dried and degreased, then dried, and dietary fiber is extracted from bean curd dregs by enzymatic method

[0037]Dry the bean dregs at 100°C and pass through a 80-mesh sieve for degreasing treatment (the degreasing refers to soaking the bean curd residues with ether 5 times the volume of the bean curd residues for 10 hours), then washing with water to remove the organic solvent, and then drying at 100°C; Add pure water to the dried bean curd residue according to the mass ratio of liquid to material 25:1, adjust the pH of the solution to 6, add papain with a mass percentage of 4%, put it in a water bath at 50°C, and use ultrasonic power of 150 W for 60 minutes of synergistic enzymolysis; Adjust the pH of the solution to 5, add 1% glucoamylase by mass, bathe in a water bath at 50°C, use an ultrasonic power of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com