Mineral substance composite type cattle-and-sheep lick block and preparation method thereof

A compound and mineral technology, applied in animal feed, animal feed, application, etc., can solve the problems of easy dehydration, licking bricks and easy deliquescence, etc., and achieve the effect of not easy to lose water and pulverize, not easy to deliquescence, and suitable for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

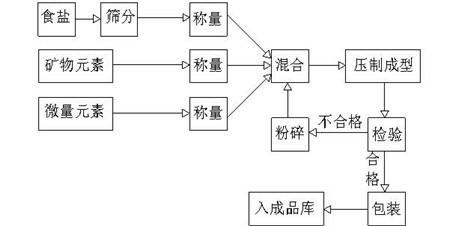

[0025] Such as figure 1 As shown, adopt the formula of following weight to prepare 1kg mineral compound type cattle and sheep licking brick.

[0026] The formula weight of licking bricks is: zinc sulfate 23.5g, copper sulfate 2g, ferrous sulfate 20g, manganese sulfate 1.5g, cobalt chloride 1.5g, potassium iodide 4g, sodium selenite 4.5g, magnesium sulfate 31g, sodium sulfate 32g, Calcium sulfate 16g, calcium hydrogen phosphate 134g, sodium chloride 730g.

[0027] (1) Sieve the table salt to remove large grains of table salt, and select table salt that can pass through a 40-mesh sieve for later use.

[0028] (2) Weigh all the substances of corresponding quality in the above formula as raw materials, stir and mix evenly, and set aside.

[0029] (3) After the mixture in step (2) is uniform, pour it into the forming mold, and press the mixture at a pressure of 400T. As a preference, the radius of the forming mold is 175mm, and the hole diameter is 35mm.

[0030] (4) Separate th...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is that the content of each component in the brick licking formula is different.

[0039] The formula of the licking brick is: zinc sulfate 21g, copper sulfate 2.5g, ferrous sulfate 16g, manganese sulfate 2g, cobalt chloride 2g, potassium iodide 5g, sodium selenite 5g, magnesium sulfate 26g, sodium sulfate 36.5g, calcium sulfate 12g, calcium hydrogen phosphate 122g, sodium chloride 750g.

Embodiment 3

[0041] The difference between this embodiment and embodiment 1 is that the content of each component in the brick licking formula is different.

[0042] The formula of the licking brick is: zinc sulfate 30g, copper sulfate 1.5g, ferrous sulfate 25g, manganese sulfate 1g, cobalt chloride 1g, potassium iodide 3g, sodium selenite 4g, magnesium sulfate 35g, sodium sulfate 27g, calcium sulfate 19.5 g, calcium hydrogen phosphate 140g, sodium chloride 713g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com