Micro-capsules of anti-influenza-virus effective part of phyllanthus urinaria, and preparation method and application thereof

A technology for anti-influenza virus and effective parts, which is applied in the direction of antiviral agents, medical preparations containing active ingredients, microcapsules, etc., and can solve the problems that the preparation of anti-influenza virus active components and its preparations of Phyllostachys phylloxera have not been reported yet. , to achieve the effect of simple preparation method, good effect and overcoming instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

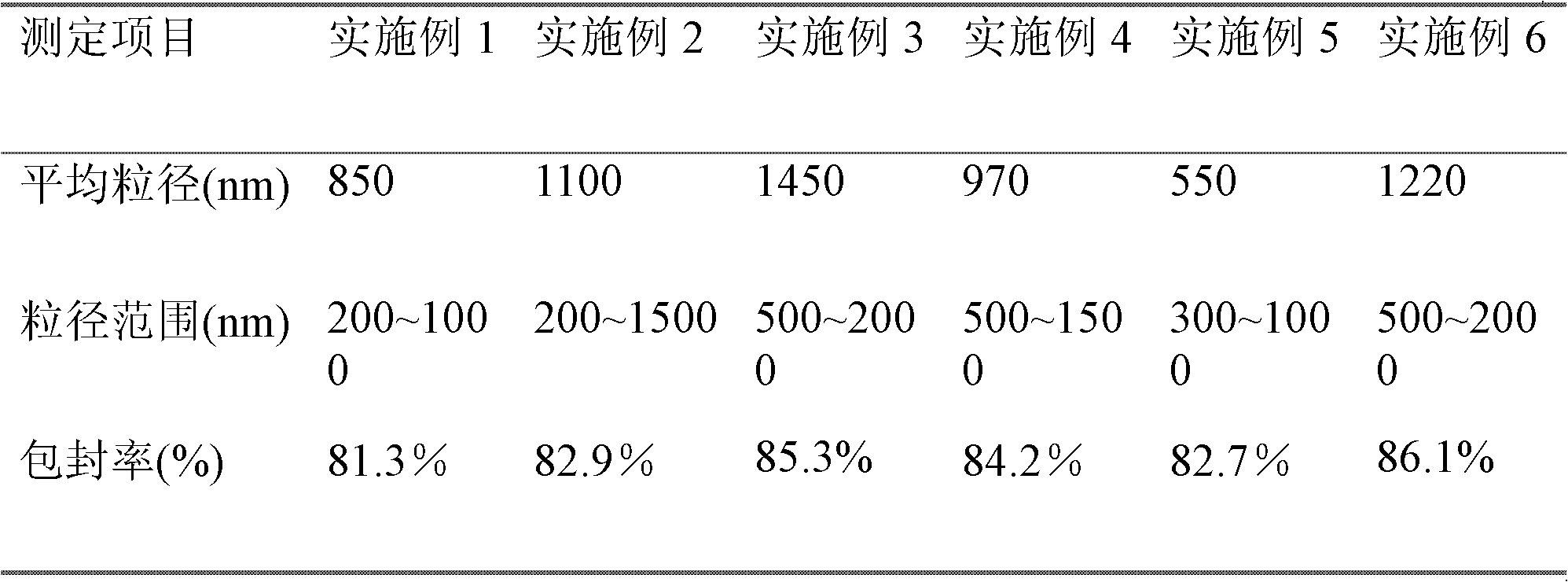

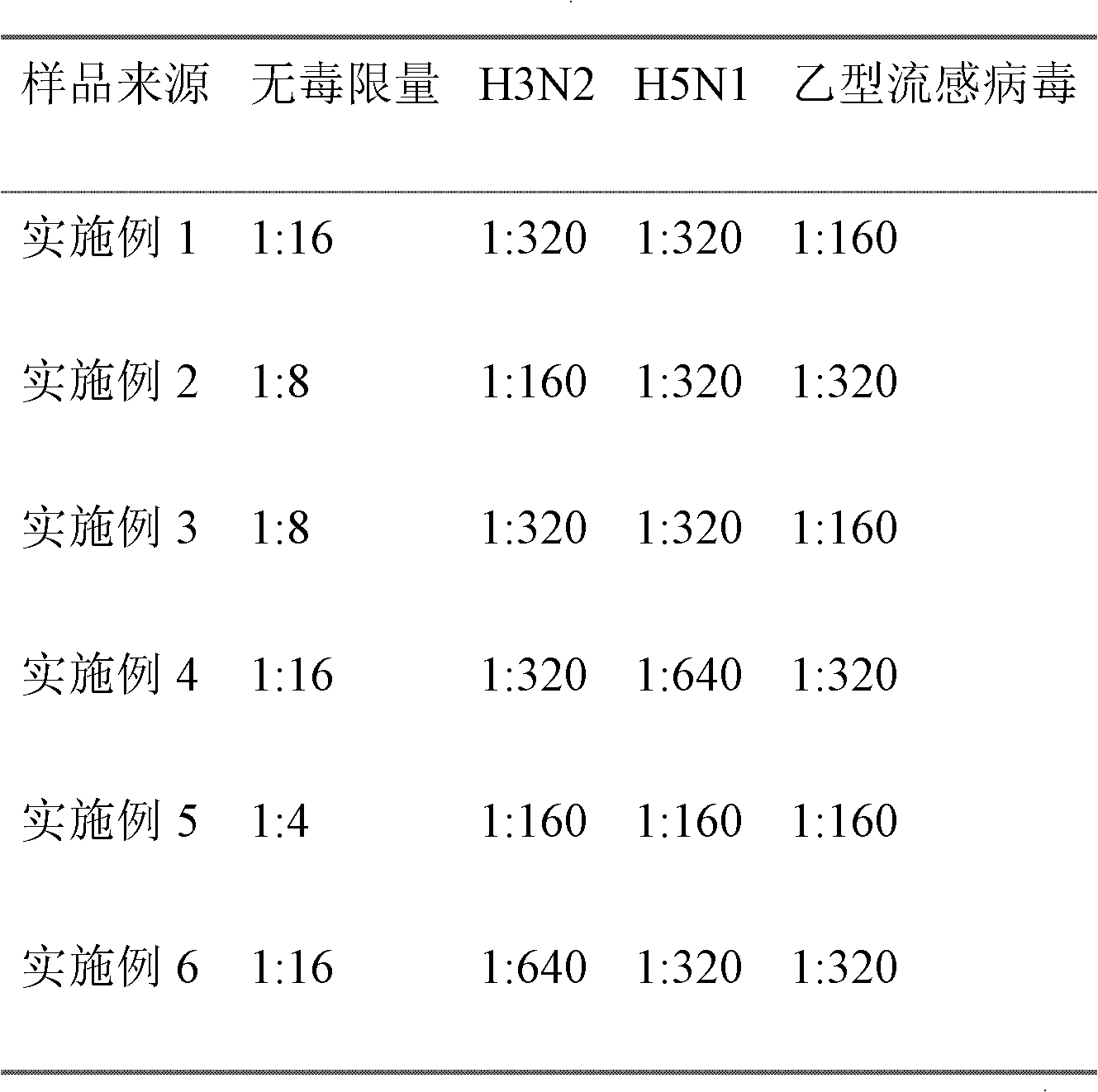

Examples

Embodiment 1

[0023] (1) 1 kg of Phyllanthus phylloxera, add 5 kg, 30% ethanol, heat and extract at 80° C. for 3 hours, filter, and then use the above-mentioned solvent to repeatedly extract the filter residue twice, filter, and combine the filtrates to 2 / 3 of the original volume in vacuum at 60° C. Add D101 macroporous resin to adsorb for 24 hours; take out the macroporous resin and elute with 90% ethanol, concentrate the eluate in vacuum at 50°C to 1 / 3 of the original volume, extract once with an equal volume of dichloromethane, combine the extracts, Concentrate in vacuo at 30°C and dry for 3 hours to obtain 55 g of anti-influenza virus effective fraction of Phyllostachys phylloxera.

[0024] (2) Acrylic resin IV100g is mixed with the capsule material solution of 5% mass fraction with dichloromethane, adds capsule material solution mass fraction 0.5% monoglyceride, 0.1% polyethylene glycol, 20% Phyllostachys anti-influenza virus The effective part is ultrasonically emulsified for 0.5 hour...

Embodiment 2

[0026] (1) 1 kg of Phyllanthus phylloxera, add 10 kg of 80% ethanol and extract by heating at 30°C for 1 hour, filter, and then repeat the extraction once with the above solvent, filter, combine the filtrate and concentrate it in vacuum at 30°C to 1 / 3 of the original volume, add DM130 The macroporous resin was adsorbed for 8 hours; the macroporous resin was taken out and eluted with 50% ethanol. When the eluate was concentrated in vacuum at 60°C to 2 / 3 of the original volume, it was extracted 3 times with an equal volume of ethyl acetate, and the extracts were combined at 50°C. Concentrate in vacuo and dry for 3 hours to obtain 102 g of anti-influenza virus effective fraction of Phyllostachys phylloxera.

[0027] (2) ethyl cellulose 100g is mixed with acetone to form a 10% mass fraction of the capsule material solution, add the capsule material solution mass fraction 5% Tween 80, 0.5% talc, and 10% Phyllophyllum anti-influenza virus effective fraction, Ultrasonic emulsificatio...

Embodiment 3

[0029] (1) 1 kg of Phyllostachys phylloxera, add 8 kg of 50% ethanol and extract by heating at 60°C for 2 hours, filter, and then use the above-mentioned solvent to repeatedly extract the filter residue once, filter, combine the filtrate and concentrate it in vacuum at 50°C to 2 / 3 of the original volume, add HPD600 The macroporous resin was adsorbed for 12 hours; the macroporous resin was taken out and eluted with 70% ethanol, and the eluate was concentrated in vacuum at 50°C to 1 / 3 of the original volume, then extracted twice with an equal volume of n-butanol, and the extracts were combined and stored at 60°C Concentrate in vacuo and dry for 5 hours to obtain 83 g of the anti-influenza virus effective fraction of Phyllanthus phylloxera.

[0030] (2) Hydroxypropyl cellulose 100g is mixed with ethanol into the capsule material solution of 8% mass fraction, adds capsule material solution mass fraction 3% Span 60, 1% silica gel, 5% Phyllostachys anti-influenza virus effective frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com