Micro-capsules of anti-influenza-virus effective part of phyllanthus urinaria, and preparation method and application thereof

A technology of anti-influenza virus and effective parts, which is applied in the directions of anti-viral agents, medical preparations containing active ingredients, microcapsules, etc., and can solve the problems of preparation of anti-influenza virus active components and preparations of P. , to achieve the effect of simple and easy preparation method, overcoming instability and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

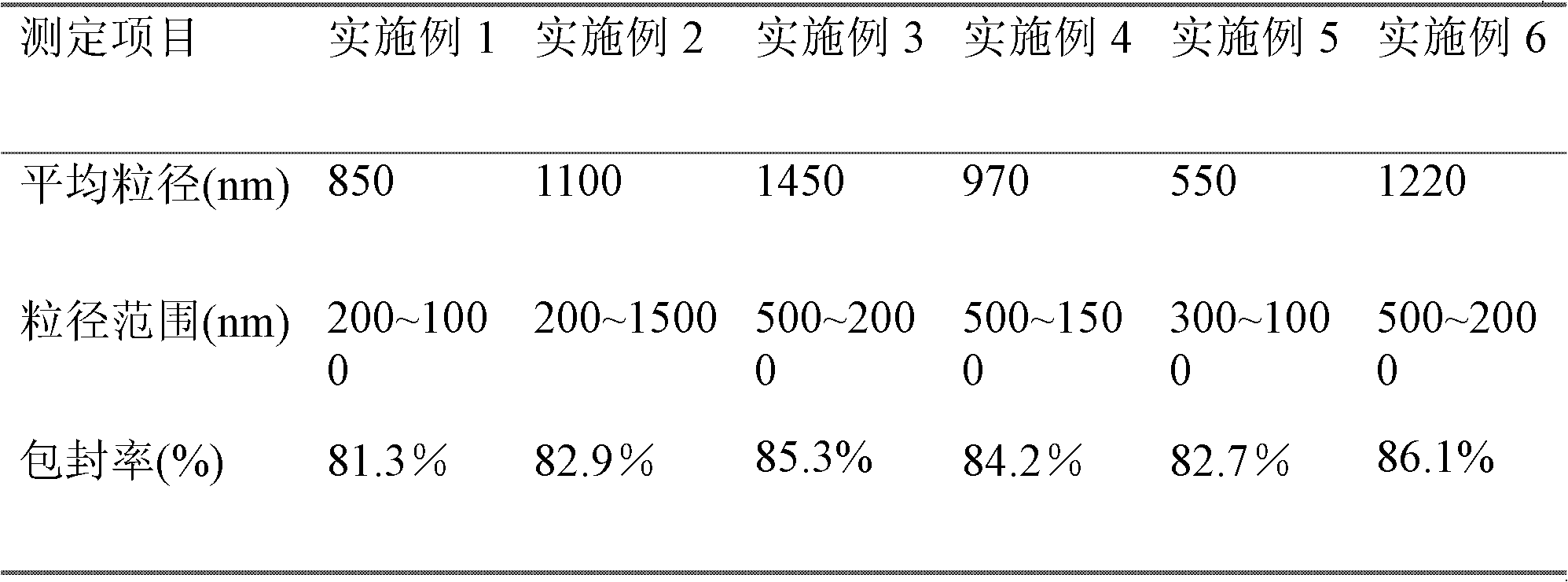

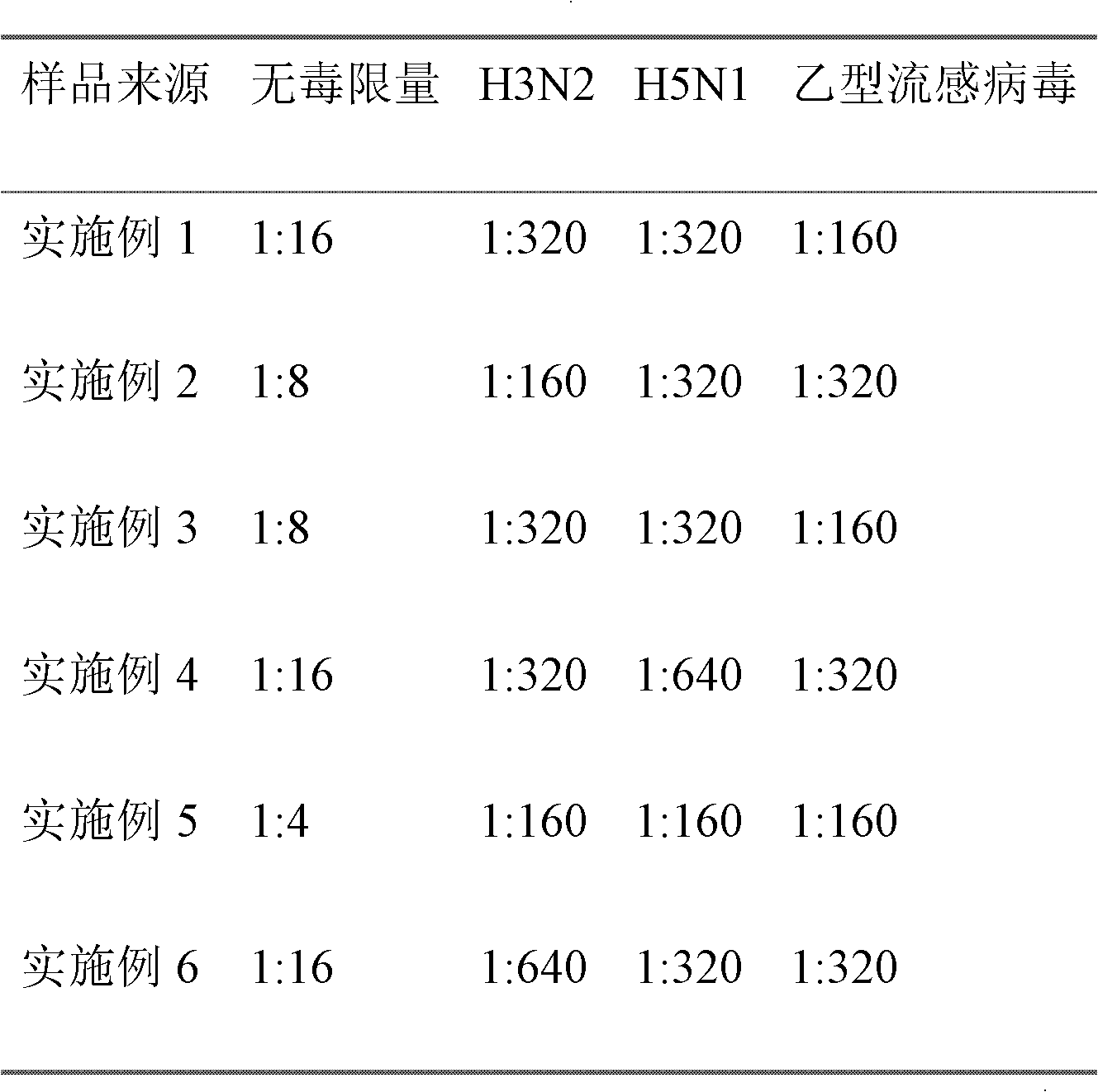

Examples

Embodiment 1

[0023] (1) 1 kg of Phyllanthus phylloxera, add 5 kg, 30% ethanol, heat and extract at 80° C. for 3 hours, filter, and then use the above-mentioned solvent to repeatedly extract the filter residue twice, filter, and combine the filtrates to 2 / 3 of the original volume in vacuum at 60° C. Add D101 macroporous resin to adsorb for 24 hours; take out the macroporous resin and elute with 90% ethanol, concentrate the eluate in vacuum at 50°C to 1 / 3 of the original volume, extract once with an equal volume of dichloromethane, combine the extracts, Concentrate in vacuo at 30°C and dry for 3 hours to obtain 55 g of anti-influenza virus effective fraction of Phyllostachys phylloxera.

[0024] (2) Acrylic resin IV100g is mixed with the capsule material solution of 5% mass fraction with dichloromethane, adds capsule material solution mass fraction 0.5% monoglyceride, 0.1% polyethylene glycol, 20% Phyllostachys anti-influenza virus The effective part is ultrasonically emulsified for 0.5 hour...

Embodiment 2

[0026] (1) 1 kg of Phyllanthus phylloxera, add 10 kg of 80% ethanol and extract by heating at 30°C for 1 hour, filter, and then repeat the extraction once with the above solvent, filter, combine the filtrate and concentrate it in vacuum at 30°C to 1 / 3 of the original volume, add DM130 The macroporous resin was adsorbed for 8 hours; the macroporous resin was taken out and eluted with 50% ethanol. When the eluate was concentrated in vacuum at 60°C to 2 / 3 of the original volume, it was extracted 3 times with an equal volume of ethyl acetate, and the extracts were combined at 50°C. Concentrate in vacuo and dry for 3 hours to obtain 102 g of anti-influenza virus effective fraction of Phyllostachys phylloxera.

[0027] (2) ethyl cellulose 100g is mixed with acetone to form a 10% mass fraction of the capsule material solution, add the capsule material solution mass fraction 5% Tween 80, 0.5% talc, and 10% Phyllophyllum anti-influenza virus effective fraction, Ultrasonic emulsificatio...

Embodiment 3

[0029] (1) 1 kg of Phyllostachys phylloxera, add 8 kg of 50% ethanol and extract by heating at 60°C for 2 hours, filter, and then use the above-mentioned solvent to repeatedly extract the filter residue once, filter, combine the filtrate and concentrate it in vacuum at 50°C to 2 / 3 of the original volume, add HPD600 The macroporous resin was adsorbed for 12 hours; the macroporous resin was taken out and eluted with 70% ethanol, and the eluate was concentrated in vacuum at 50°C to 1 / 3 of the original volume, then extracted twice with an equal volume of n-butanol, and the extracts were combined and stored at 60°C Concentrate in vacuo and dry for 5 hours to obtain 83 g of the anti-influenza virus effective fraction of Phyllanthus phylloxera.

[0030] (2) Hydroxypropyl cellulose 100g is mixed with ethanol into the capsule material solution of 8% mass fraction, adds capsule material solution mass fraction 3% Span 60, 1% silica gel, 5% Phyllostachys anti-influenza virus effective frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com