Safety production device and process for dimethyl sulfide oxidation reaction

A technology of dimethyl sulfide and oxidation reaction, which is applied in the chemical method, feeding device, preparation of organic compounds, etc. to make liquid react with gas medium, and can solve the problem of endangering the safety of oxidation tower, unreasonable distribution effect, accident and other problems to achieve the effect of preventing explosion accidents, ensuring safe and stable operation, and preventing excess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

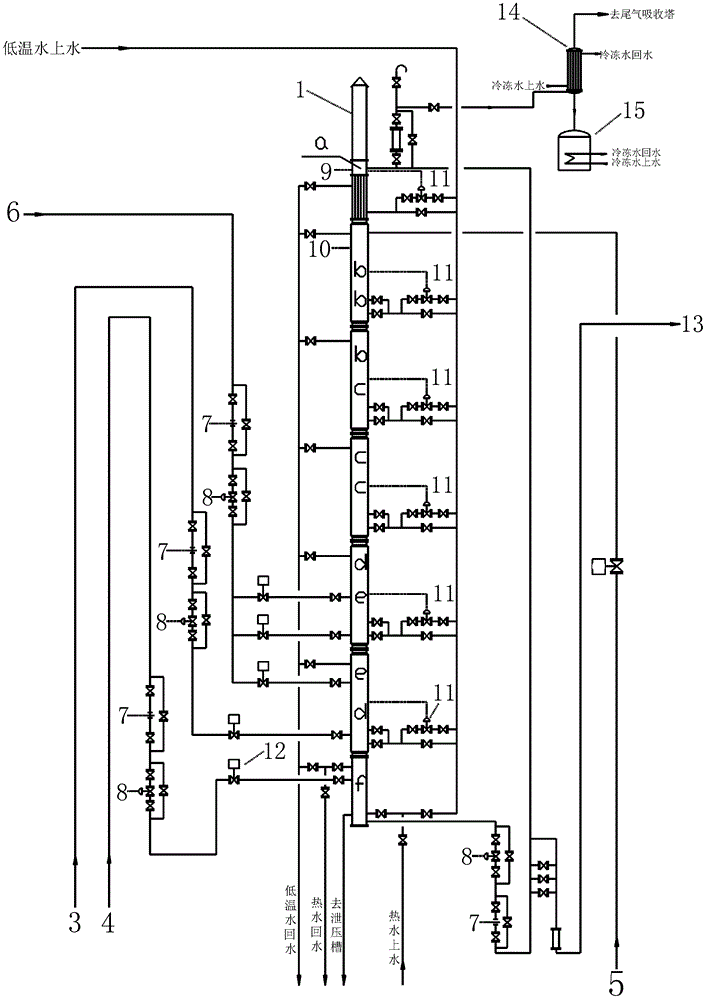

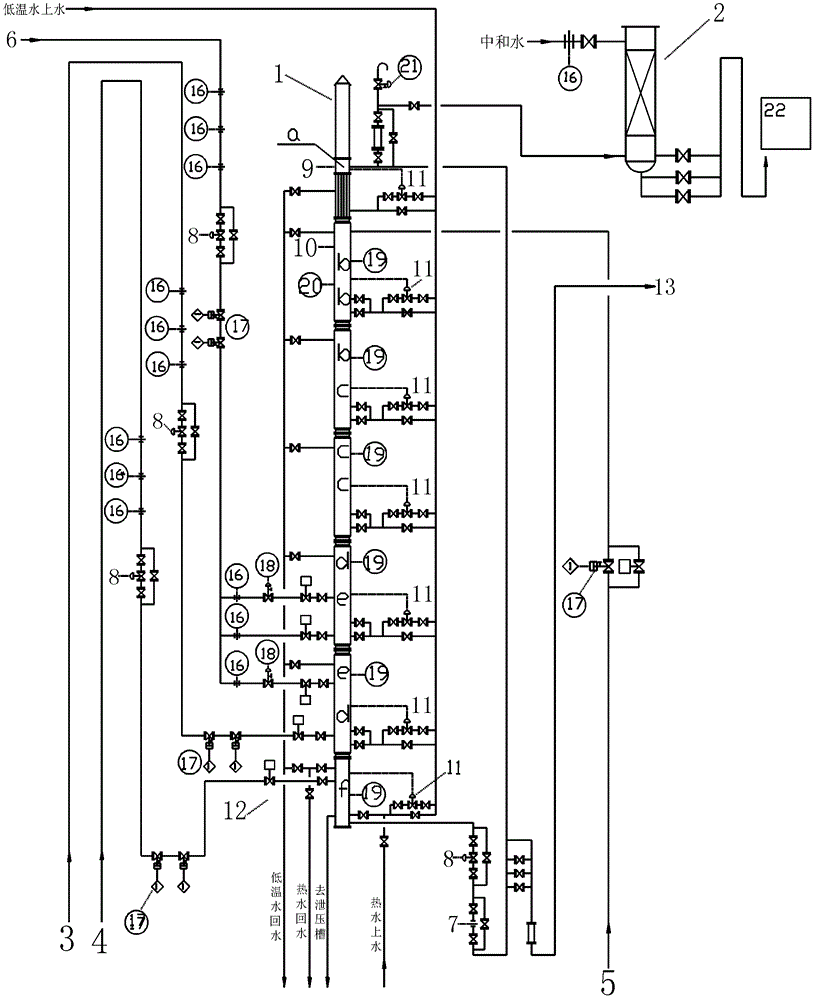

[0062] A safe production process for the oxidation reaction of dimethyl sulfide. The dosage of nitrogen dioxide, oxygen and refined sulfide is strictly controlled, and the feed flow rate of sulfide is 300kg / h, and the feed flow rate of oxygen is 60Nm 3 / h, nitrogen dioxide feed flow rate 15Nm 3 / h feed nitrogen dioxide first, then oxygen, and finally fine sulfide, control the temperature of each tower section of the oxidation tower, the heating zone at the bottom of the tower is 40-50°C, the main reaction zone is 60-75°C, and the side reaction zone 55-65°C, remaining reaction zone 40-60°C, absorption zone 25-35°C, gas-phase zone 20-30°C; the tail gas produced by the oxidation reaction is neutralized in water.

[0063] The inlet pressure of oxygen is 0.3MPa, the inlet pressure of nitrogen dioxide is 0.3MPa, and the pressure in the oxidation tower is ≤3KPa. Oxidation tower liquid level is 50%. The color of the liquid in the oxidation tower is yellow to light green, and the col...

Embodiment 2

[0065] A safe production process for the oxidation reaction of dimethyl sulfide. The dosage of nitrogen dioxide, oxygen and refined sulfide is strictly controlled, and the feed flow rate of sulfide is 400kg / h, and the flow rate of oxygen feed is 80Nm 3 / h, nitrogen dioxide feed flow rate 30Nm 3 / h feed nitrogen dioxide first, then oxygen, and finally fine sulfide, control the temperature of each tower section of the oxidation tower, the heating zone at the bottom of the tower is 40-50°C, the main reaction zone is 60-75°C, and the side reaction zone 55-65°C, remaining reaction zone 40-60°C, absorption zone 25-35°C, gas-phase zone 20-30°C; the tail gas produced by the oxidation reaction is neutralized in water.

[0066] The inlet pressure of oxygen is 0.3MPa, the inlet pressure of nitrogen dioxide is 0.3MPa, and the pressure in the oxidation tower is ≤3KPa. Oxidation tower liquid level is 60%. The color of the liquid in the oxidation tower is yellow to light green, and the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com