Alginate/halloysite nanotube composite-porous ball and preparation method therefor

A halloysite nanotube, alginate technology, applied in silicate, chemical instruments and methods, aluminum silicate, etc., can solve the problems of complex modification process of adsorbent, restricting large-scale application, poor mechanical stability, etc. , to achieve the effect of easy separation and regeneration, maintaining mechanical and chemical stability, and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 2g of halloysite nanotube powder and add it into 100ml of water, and stir at high speed to disperse the nanotubes evenly in the water. Add 2 g of sodium alginate particles into the halloysite nanotube suspension, and continue stirring to completely dissolve the sodium alginate to obtain a sodium alginate / halloysite nanotube mixed viscous liquid in which the halloysite nanotubes are uniformly dispersed. The sodium alginate / halloysite nanotube mixed mucus was added dropwise to the calcium chloride solution at a uniform speed, and solidified to form particles. The particles are filtered and washed repeatedly with water to remove residual calcium ions on the surface of the particles. The particles are dried to obtain dry alginate / halloysite nanotube composite porous balls.

[0027] The digital photos of the prepared alginate / halloysite nanotube composite porous spheres are shown in figure 1 ;

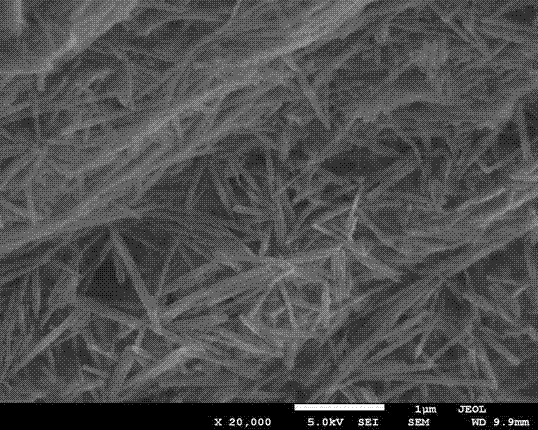

[0028] Scanning electron microscopy (SEM) analysis of the as-prepared al...

Embodiment 2

[0032] Take 2g of halloysite nanotube powder and add it into 200ml of water, and stir at high speed to make the nanotubes evenly dispersed in the water. Add 5 g of sodium alginate particles into the halloysite nanotube suspension, and continue stirring to completely dissolve the sodium alginate to obtain a sodium alginate / halloysite nanotube mixed viscous liquid in which the halloysite nanotubes are uniformly dispersed. The sodium alginate / halloysite nanotube mixed mucus was added dropwise to the calcium chloride solution at a uniform speed, and solidified to form particles. The particles are filtered and washed repeatedly with water to remove residual calcium ions on the surface of the particles. The particles are dried to obtain dry alginate / halloysite nanotube composite porous balls.

[0033] Scanning electron microscopy (SEM) analysis of the as-prepared alginate / halloysite nanotube composite porous spheres is shown in Figure 4

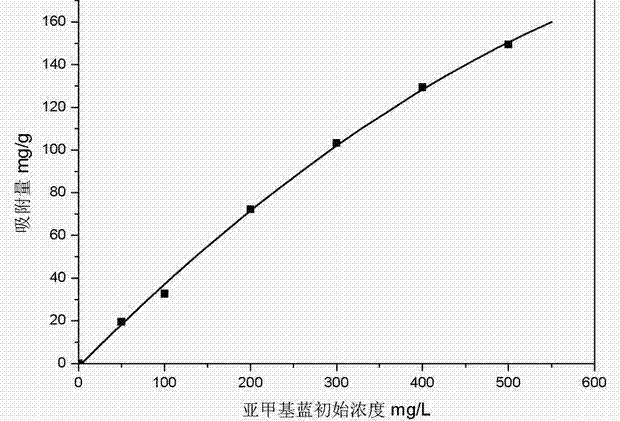

[0034] The adsorption effect of the prep...

Embodiment 3

[0037] Take 9g of halloysite nanotube powder and add it into 1000ml of water, and stir at a high speed, so that the nanotubes are evenly dispersed in the water. Add 5 g of sodium alginate particles into the halloysite nanotube suspension, and continue stirring to obtain a sodium alginate / halloysite nanotube mixed viscous liquid in which the halloysite nanotubes are uniformly dispersed. The sodium alginate / halloysite nanotube mixed mucus was added dropwise into the barium chloride solution at a uniform speed, and solidified to form particles. The particles are filtered and washed repeatedly with water to remove residual barium ions on the surface of the particles. The particles are dried to obtain dry alginate / halloysite nanotube composite porous balls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com