Preparation and using method of Ag@AgI/AgBr modified TiO2 nanometer tube photochemical catalyst

A photocatalyst and nanotube technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem that catalysts need to be further improved, and achieve excellent stability and visible light response performance, tubular structure. Complete, photocatalytic activity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

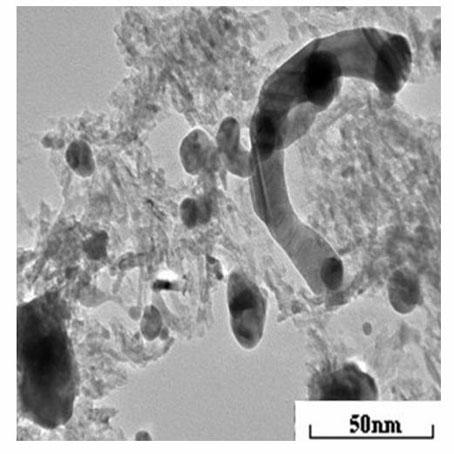

[0024] Step (1): First weigh 1 g of P25 nano-TiO 2 Dispersed in 80 mL, 10 mol / dm 3 Magnetically stirred in NaOH solution for 0.5 h, then placed in a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, and reacted at a constant temperature in an oven at 110 °C for 24 h; took out the hydrothermal kettle, cooled to room temperature, filtered and rinsed with deionized water Wash to pH = 7.0, then precipitate at 0.1 mol / dm 3 HNO 3 The solution was magnetically stirred overnight, then washed with deionized water until neutral, and finally dried at 60 °C for 24 h, and raised to 500 °C in a muffle furnace at a rate of 2 °C / min, kept for 2 h, and cooled to room temperature , to obtain TiO after calcination 2 nanotubes (TNTs).

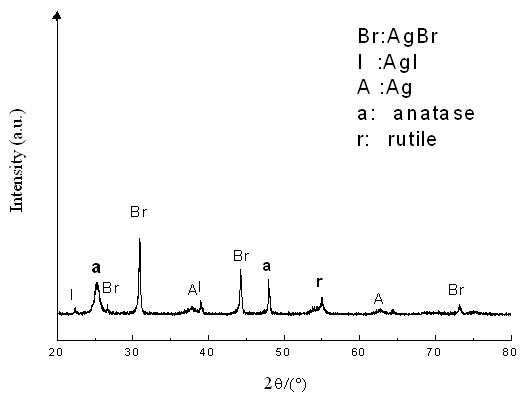

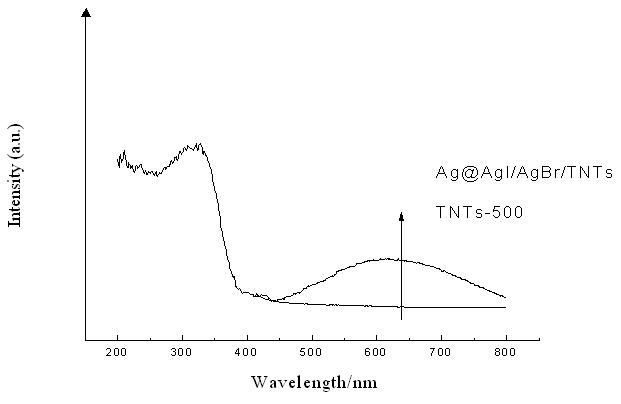

[0025] Step (2): Weigh 0.64 g of TNTs prepared in step (1) and disperse in 100 mL of distilled water, ultrasonically disperse for 30 min, and then add 8 ml, 0.1 mol / dm 3 AgNO 3 The solution was magnetically stirred for 30 min. Add 8 m...

Embodiment 2

[0028] Synthesize TNTs according to step (1) in Example 1, weigh 0.64 g of the prepared TNTs and disperse them in 100 mL of distilled water, ultrasonically disperse for 30 min, and then add dropwise 8 ml of 0.1 mol / dm 3 AgNO 3 The solution was magnetically stirred for 30 min. Add 8ml, 0.1mol / dm 3 The KBr solution was slowly added dropwise to the above system, and stirring was continued for 3 h after the dropwise addition was completed. Then 0.08 ml of 0.1 mol / dm was added dropwise 3 The aqueous solution of KI, makes AgI add-on amount be 1% of AgBr add-on amount, stir overnight after completion of dropwise addition. Suction filtration, washing with water three times, drying at 80 °C for 12 h, and irradiating for 7 min under a 500 W tungsten-halogen lamp gave the AgAgI / AgBr / TNTs composite photocatalyst.

[0029] According to the method of step (3) in Example 1, after the 500 W tungsten halogen light was illuminated for 60 min, the degradation rate of the catalyst to the meth...

Embodiment 3

[0031] Synthesize TNTs according to step (1) in Example 1, weigh 0.64 g of the prepared TNTs and disperse them in 100 mL of distilled water, ultrasonically disperse for 30 min, and then add dropwise 8 ml of 0.1 mol / dm 3 AgNO 3 The solution was magnetically stirred for 30 min. Then add 8ml, 0.1mol / dm 3 The KBr solution was slowly added dropwise to the above system, and stirring was continued for 3 h after the dropwise addition was completed. Then add 0.2 ml dropwise, 0.1 mol / dm 3 The aqueous solution of KI, makes AgI add-on amount be 2.5% of AgBr add-on amount, stir overnight after finishing dropwise. Suction filtration, washing with water three times, drying at 100 °C for 12 h, and irradiating for 7 min under a 500 W tungsten-halogen lamp gave the AgAgI / AgBr / TNTs composite photocatalyst.

[0032] According to the method of step (3) in Example 1, after 60 min of 500 W tungsten light irradiation, the degradation rate of the catalyst to the methyl orange solution was 55.6% (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com