Device and method for preparing superfine nickel powder

A nickel powder, one-way technology, applied in the field of ultra-fine metal nickel powder preparation equipment, can solve the problems of cohesive loss, poor fluidity of ultra-fine nickel powder, etc., achieve sufficient gas-solid contact, fast reaction rate, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

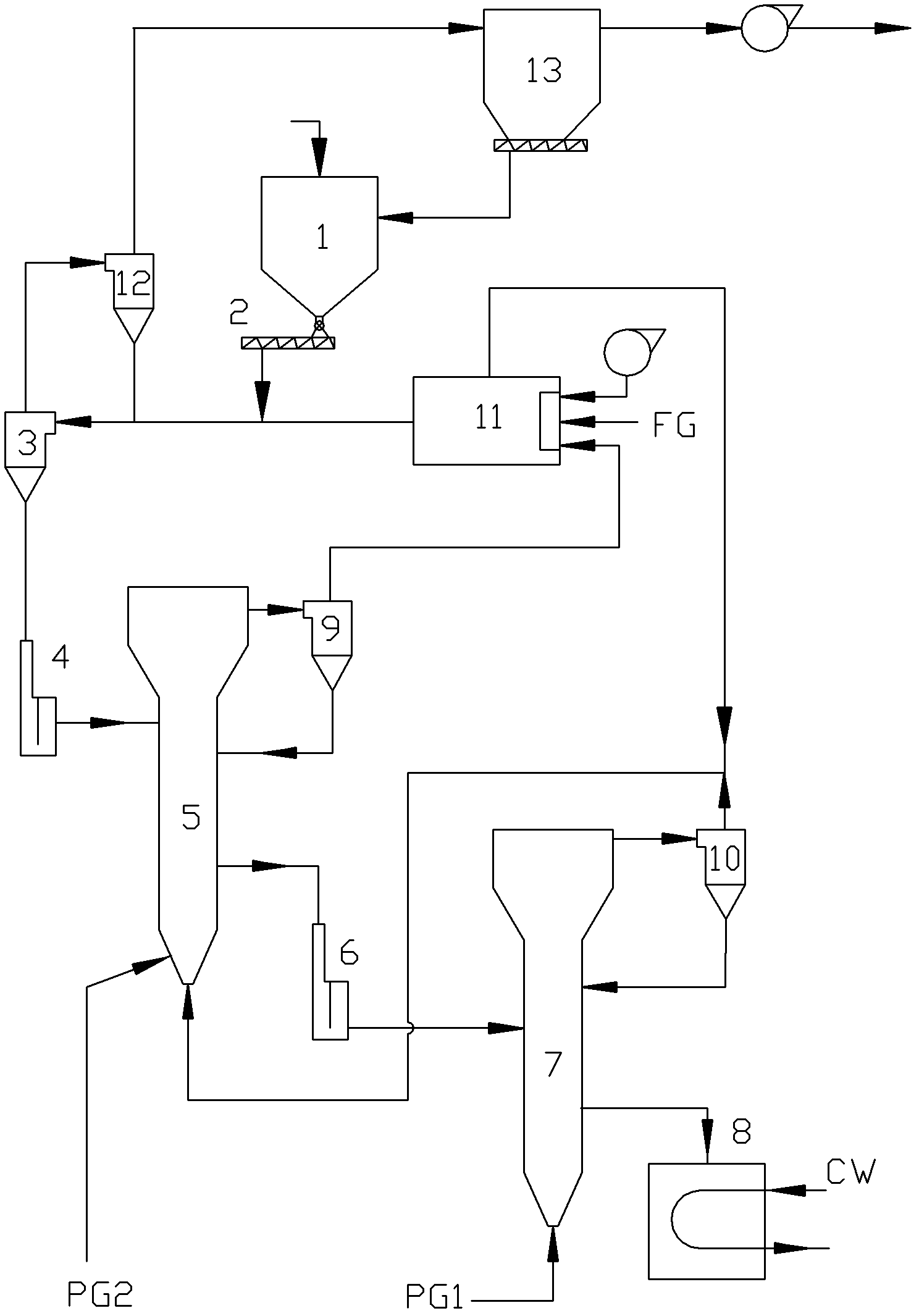

[0032] Such as figure 1 Shown, a kind of device for preparing superfine nickel powder comprises the screw feeder 2, cyclone preheater 3, fluidized bed reactor 5 and fluidized bed cooler 7 of the hopper 1 connected successively and hopper 1 below; The outlet of the fluidized bed reactor 5 is connected with a combustion chamber 11, and the outlet of the combustion chamber 11 is connected with the cyclone preheater 3.

[0033] A first cyclone separator 9 is provided between the fluidized bed reactor 5 and the combustion chamber 11 .

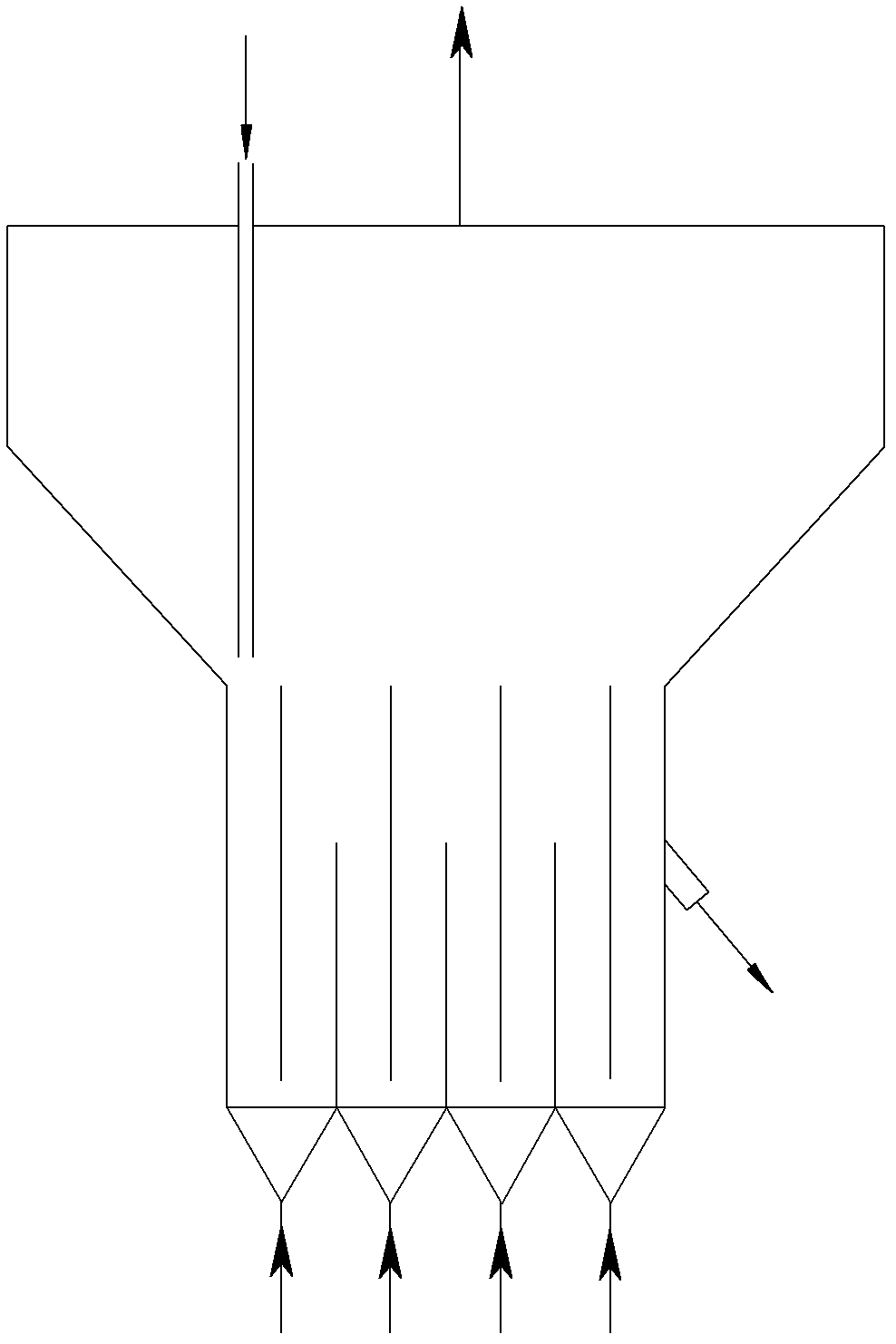

[0034] The fluidized bed cooler 7 is provided with a circulating water cooler 8, and a high-pressure carrier gas inlet is provided below, and the outlet is connected to the second cyclone separator 10; the outlet of the second cyclone separator 10 communicates with the combustion chamber 11 and is connected to the fluidized bed Reactor 5 is connected.

[0035] The top of the cyclone preheater 3 is connected with the cyclone dust collector 12 and t...

Embodiment 2

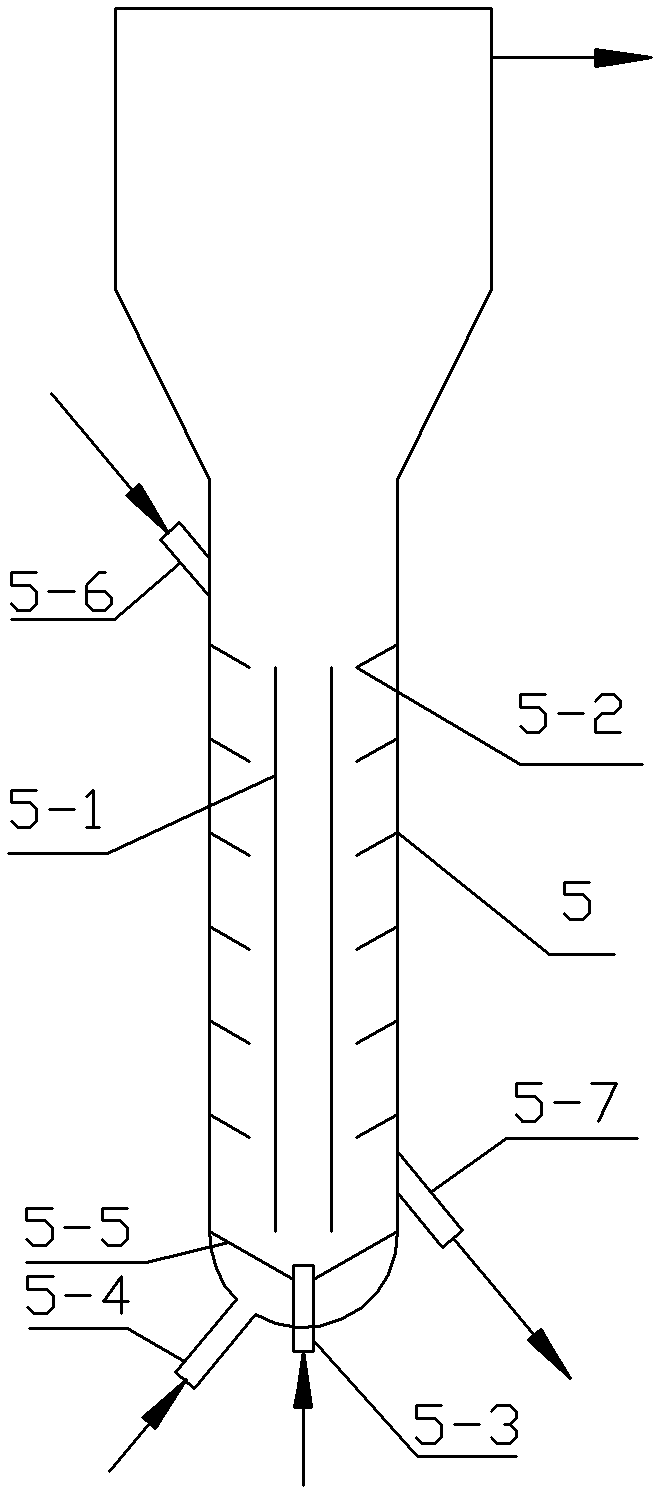

[0038] Such as figure 2 As shown, the feed port 5-6 of the countercurrent fluidized bed reactor is on the top, and the discharge port 5-7 is on the bottom, forming an angle of 40° with the vertical direction. A guide tube 5-1 is arranged inside, and a first carrier gas inlet 5-3 is provided under the guide tube 5-1; a second carrier gas inlet 5-4 is provided under the counterflow fluidized bed reactor, and a gas carrier inlet 5-4 is arranged on it. Distributor 5-5; a transverse baffle 5-2 is set in the annular area between the guide tube 5-1 and the reactor wall; the transverse baffle 5-2 is 5° to the horizontal direction; the transverse baffle 5-2 There is a small hole on the top, and the diameter of the hole is 2.0mm.

Embodiment 3

[0040] The feed port 5-6 of the countercurrent fluidized bed reactor is on the top, and the discharge port 5-7 is on the bottom, forming an angle of 25° with the vertical direction. A guide tube 5-1 is arranged inside, and a first carrier gas inlet 5-3 is provided under the guide tube 5-1; a second carrier gas inlet 5-4 is provided under the counterflow fluidized bed reactor, and a gas carrier inlet 5-4 is arranged on it. Distributor 5-5; a transverse baffle 5-2 is set in the annular area between the guide tube 5-1 and the reactor wall; the transverse baffle 5-2 is 30° to the horizontal direction; the transverse baffle 5-2 There is a small hole on it, and the diameter of the hole is 0.05mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com