Method for preparing leaf-shaped nanometer silver-copper alloy

A nano-silver and copper alloy technology, which is applied in the field of preparing leaf-shaped nano-silver-copper alloys, can solve the problems that nano-silver-copper alloys have not been reported, and achieve good mechanical properties, easy to repeat operations, and increase the reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

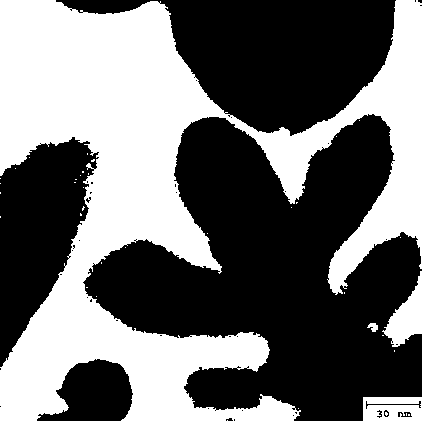

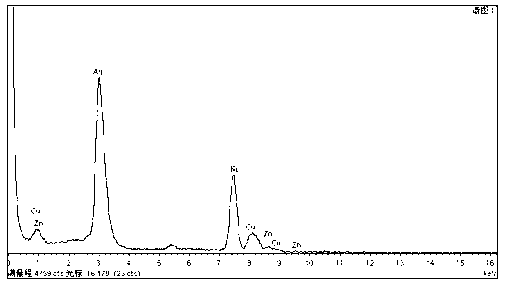

[0022] Cut the copper-zinc alloy sheet with a thickness of 0.3mm and 38% zinc (mass fraction) into a size of about 10mm×10mm, and then use 1000# water sandpaper to grind the surface of the copper-zinc alloy to remove the oxide film on the surface, and put the polished copper-zinc Put the alloy into acetone and distilled water successively, each ultrasonic cleaning for 10 minutes, then rinse the copper-zinc alloy surface with absolute ethanol to remove impurities, dry it, and immerse the dried copper-zinc alloy in pre-prepared 10mmol / L Silver nitrate solution, after 5 seconds the surface of the copper-zinc alloy turns dark gray, take it out, wash it with distilled water to remove excess salt on the surface, dry it naturally, put the S-Y-S tubular resistance furnace in industrial pure nitrogen (oxygen partial pressure is about 0.0001atm) after heating up to 200°C and stabilizing for 30 minutes, put the copper-zinc alloy into a flat-bottomed crucible and place it in the middle of ...

Embodiment 2

[0029] Cut a copper-zinc alloy sheet with a thickness of 0.3mm and a zinc content of 36% (mass fraction) into a size of about 10mm×10mm, then use 1000# water-grinding sandpaper to grind the surface of the copper-zinc alloy to remove the oxide film on the surface, and put the polished copper-zinc Put the alloy into acetone and distilled water successively, each ultrasonic cleaning for 10 minutes, then rinse the surface of the copper-zinc alloy with absolute ethanol to remove impurities, dry it, and immerse the dried copper-zinc alloy in pre-prepared 5mmol / L Silver nitrate solution, after 60s the surface of the copper-zinc alloy becomes dark gray, take it out, wash it with distilled water to remove excess salt on the surface, dry it naturally, put the S-Y-S tubular resistance furnace in an argon-oxygen mixture with an oxygen partial pressure of 0.001atm After heating up to 100°C in air and stabilizing for 30 minutes, put the copper-zinc alloy into a flat-bottomed crucible and pla...

Embodiment 3

[0032] Cut the copper-zinc alloy sheet with a thickness of 0.3mm and 38% zinc (mass fraction) into a size of about 10mm×10mm, and then use 1000# water sandpaper to grind the surface of the copper-zinc alloy to remove the oxide film on the surface, and put the polished copper-zinc Put the alloy into acetone and distilled water successively, each ultrasonic cleaning for 10 minutes, then rinse the copper-zinc alloy surface with absolute ethanol to remove impurities, dry it, and immerse the dried copper-zinc alloy in pre-prepared 10mmol / L Silver nitrate solution, after 5 seconds, the surface of the copper-zinc alloy becomes dark gray, take it out, wash it with distilled water to remove excess salt on the surface, dry it naturally, put the S-Y-S tubular resistance furnace in the nitrogen oxygen with an oxygen partial pressure of 0.01atm After heating up to 300°C in the mixed gas and stabilizing for 30 minutes, put the copper-zinc alloy into a flat-bottomed crucible and place it in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com