Mixed microwave sintering method of alpha-Al203 powder

A hybrid microwave and sintering technology, applied in the preparation of alumina/hydroxide, can solve the problems of environmental pollution, long powder sintering time, and high energy consumption, improve purity, and achieve grain refinement and uniformity. energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

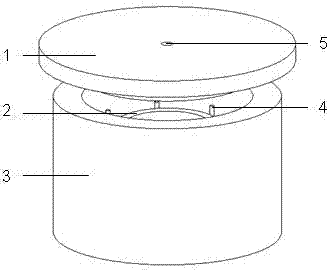

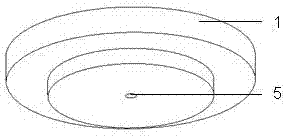

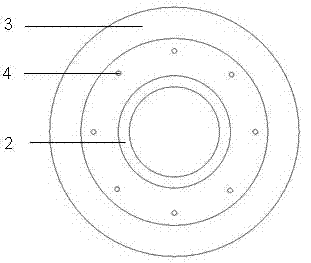

[0035] Such as Figure 1~4 The auxiliary heating and heat preservation device shown: includes inner and outer double-layer insulation layers 2, 3, the inner and outer double-layer insulation layers 2, 3 are nested and formed by inner and outer cylinders, and the inner layer insulation layer 2 is lower than the outer layer insulation layer 3, Auxiliary heating bodies 4 are evenly distributed along the circumferential direction between the inner and outer double-layer insulation layers 2 and 3, and the top of the inner and outer double-layer insulation layers 2 and 3 is provided with a cover plate 1 matching its shape, and an infrared temperature detector is provided on the cover plate 1 Hole 5, wherein the auxiliary heating body 4 is a SiC heating rod, the distance between the SiC heating rod and the inner and outer double-layer insulation layers 2 and 3 is 1~3cm, and the distance between the inner layer insulation layer 2 and the center of the device (where the sample is placed...

Embodiment 2

[0040] Basically the same as Example 1, the difference is that the raw material is ammonium aluminum sulfate dodecahydrate powder, the sample mass is 50g, when the reflected power is basically stable, the heating rate is maintained at 15±3°C / min, and the temperature is raised to a sintering temperature of 1200°C at a uniform speed. ℃, the holding time is 15min, and the microwave input power is controlled to cool down to room temperature at a constant speed of 20±3℃ / min. The whole sintering process lasted about 130min.

[0041] The resulting α-Al 2 o 3 The particle size distribution of the powder is uniform, about 0.2 μm, high purity, loose particle surface, soft agglomeration, and easy grinding. Its X-ray diffraction pattern is shown in Figure 7 . α-Al 2 o 3 The scanning electron microscope photograph of the cross-section of the powder is as follows: Figure 10 As can be seen from the figure, α-Al 2 o 3 The particle size of the powder is uniform and spherical, and th...

Embodiment 3

[0043] Basically the same as Example 1, the difference is that the raw material is aluminum oxide monohydrate powder, and the sample mass is 100g. When the reflected power is basically stable, the heating rate is maintained at 30±3°C / min, and the temperature is raised to a sintering temperature of 1000°C at a uniform speed. The holding time is 20 minutes, and the microwave input power is controlled to cool to room temperature at a constant speed of 6±3°C / min. The whole sintering process lasted about 250min.

[0044] The resulting α-Al 2 o 3 The particle size distribution of the powder is uniform, about 0.2μm, high purity, fine and uniform crystal grains, and easy to disperse. Its X-ray diffraction pattern is shown in Figure 8 . α-Al 2 o 3 The scanning electron microscope photograph of the cross-section of the powder is as follows: Figure 11 As can be seen from the figure, α-Al 2 o 3 The grain size of the powder is uniform and spherical, and the grain boundaries are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com