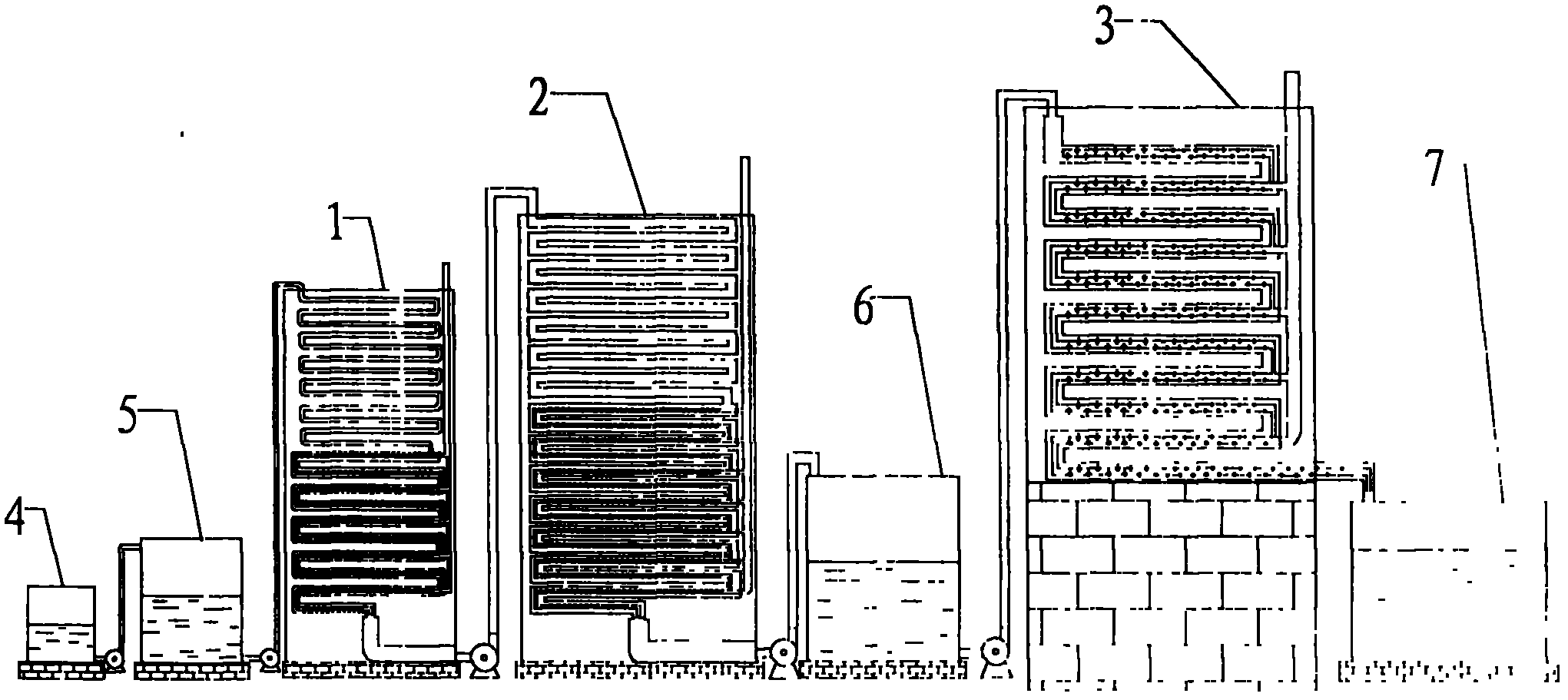

Carbonizer and method for producing nano calcium carbonate

A nano-calcium carbonate and carbonizer technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve problems such as long reaction time, product fluctuation, and irregular crystal structure of products, and achieve regular crystal structure and particle size distribution Uniform and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

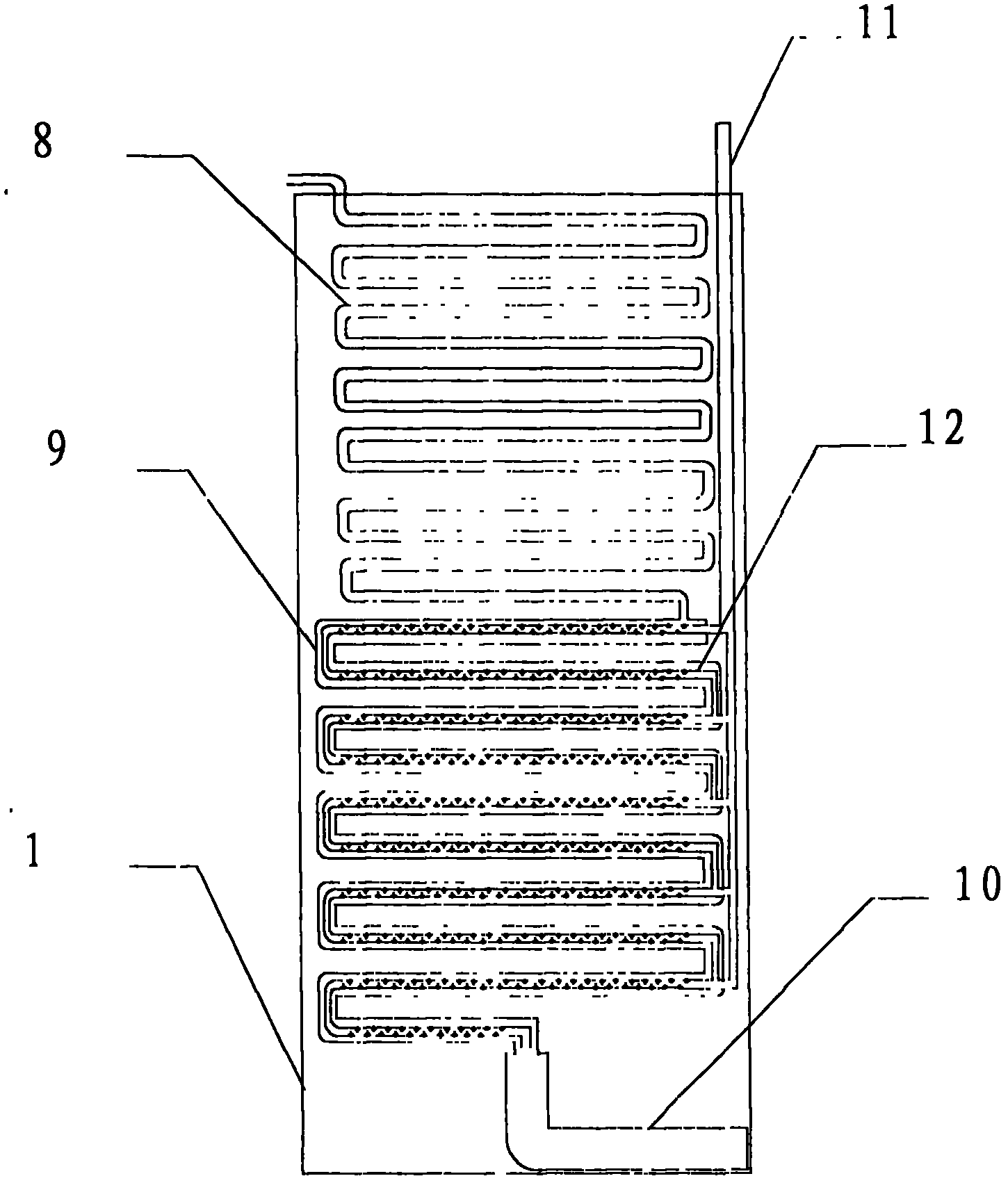

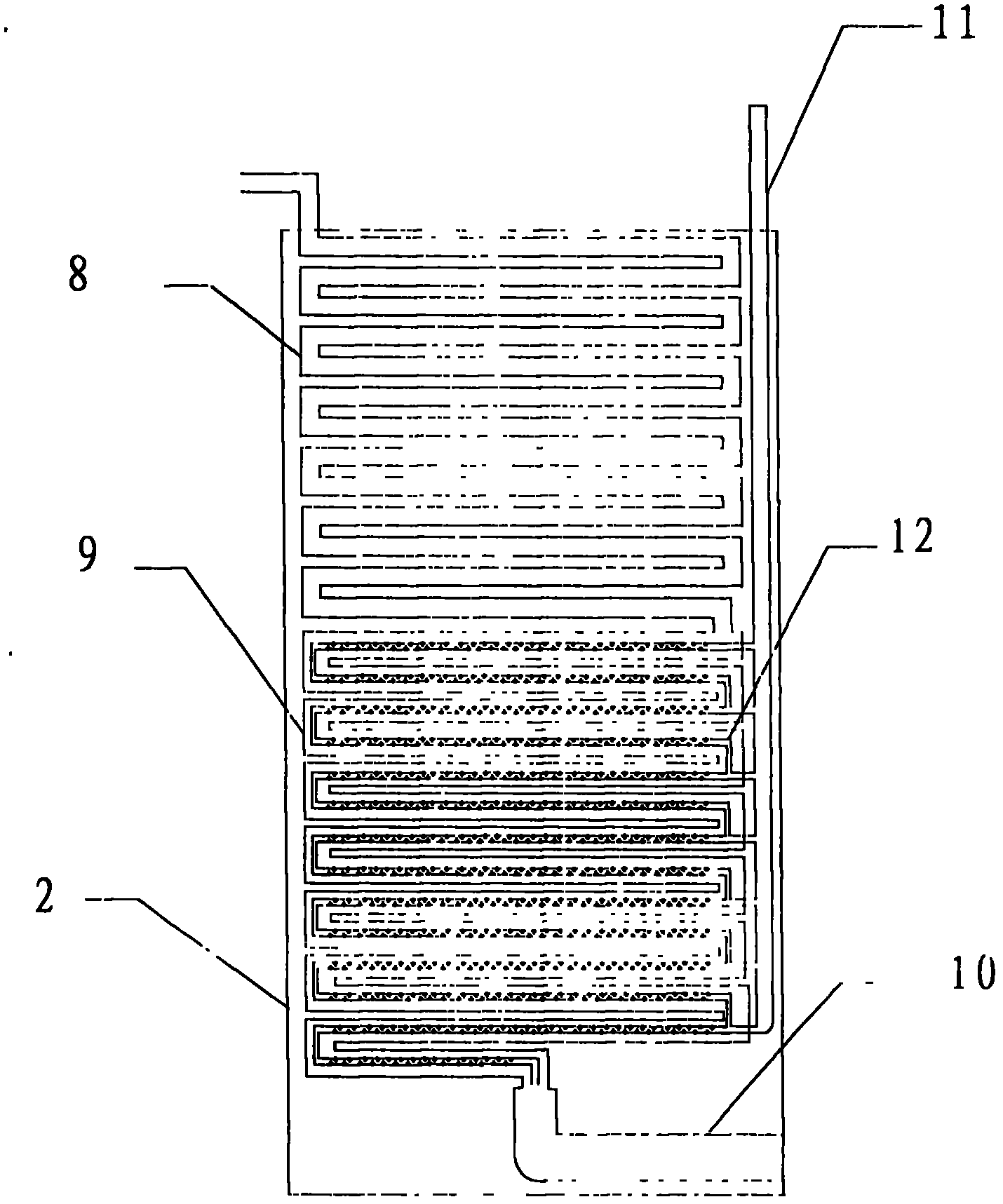

Method used

Image

Examples

Embodiment 1

[0064] Adjust the calcium hydroxide slurry with a calcium hydroxide mass concentration of 6% to 15% in the calcium hydroxide blending pool, store the calcium hydroxide slurry in the calcium hydroxide slurry storage pool after deployment, The temperature of the calcium hydroxide slurry in it is controlled between 10°C and 30°C, and the crystal form directing agent magnesium chloride, magnesium sulfate, and sodium silicate are added at a mass percentage of 0.1% to 2% on the dry basis of calcium hydroxide. For one of them, add 0.1 to 2% sodium hexametaphosphate as a dispersant, mix and stir evenly, and then pump calcium hydroxide slurry into the primary carbonization nucleation reactor, and pass into the primary carbonization nucleation reactor. carbon dioxide gas, the volume concentration of carbon dioxide is ≥ 20%, and the carbon dioxide gas introduced is continuously contacted and reacted with the slurry in the slurry carbonization reaction tube.

[0065] The reaction rate is ...

Embodiment 2

[0070] In the calcium hydroxide blending pool, adjust the calcium hydroxide slurry with a calcium hydroxide mass concentration of 5% to 10%, and store the calcium hydroxide slurry in the calcium hydroxide slurry storage pool after blending. Control the temperature of the calcium hydroxide slurry in the calcium hydroxide slurry storage tank between 10°C and 30°C, and add 0.4% of the crystal form directing agent magnesium chloride and magnesium sulfate based on the dry basis of calcium hydroxide , sodium silicate, add 0.2-2% sodium hexametaphosphate as a dispersant, mix and stir evenly, pump calcium hydroxide slurry into the primary carbonization nucleation reactor, and pump it into the primary carbonization nucleation reactor The carbon dioxide gas that has been purified is passed into the middle, the volume concentration of carbon dioxide is ≥ 20%, and the carbon dioxide gas passed in is continuously contacted and reacted with the slurry in the slurry carbonization reaction tub...

Embodiment 3

[0076] In the calcium hydroxide blending pool, adjust the calcium hydroxide slurry with a calcium hydroxide mass concentration of 5% to 10%, and store the calcium hydroxide slurry in the calcium hydroxide slurry storage pool after blending. Control the temperature of the calcium hydroxide slurry in the calcium hydroxide slurry storage tank between 20°C and 40°C, and add 0.3% of the crystal form directing agent magnesium chloride and magnesium sulfate based on the dry basis of calcium hydroxide , one of sodium silicate and 0.2-2% sodium hexametaphosphate as a dispersant, after mixing and stirring evenly, pump calcium hydroxide slurry into the primary carbonization nucleation reactor, and pass through the primary carbonation nucleation reactor The carbon dioxide gas that has been purified is introduced, and the volume concentration of carbon dioxide is ≥ 20%. The carbon dioxide gas introduced is continuously contacted and reacted with the slurry in the slurry carbonization reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com