Biological liquid organic fertilizer and preparation method thereof

A technology of biological liquid and production method, which is applied to the treatment of biological organic parts, organic fertilizers, waste fuels, etc., can solve the problems of food safety threats in greenhouses, soil compaction damage, and inability to transport long distances, and achieve obvious effects of increasing production. The effect of uniform growth and elimination of pollution hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, a biological liquid organic fertilizer, which is composed of biogas residue, biogas slurry and beneficial microbial flora; the biogas residue is animal manure and straw; the beneficial microbial flora is lactic acid bacteria, bacillus and yeast; its The weight percentage is 38-44% of biogas residue, 40-54% of biogas slurry and 6-12% of beneficial microbial flora.

Embodiment 2

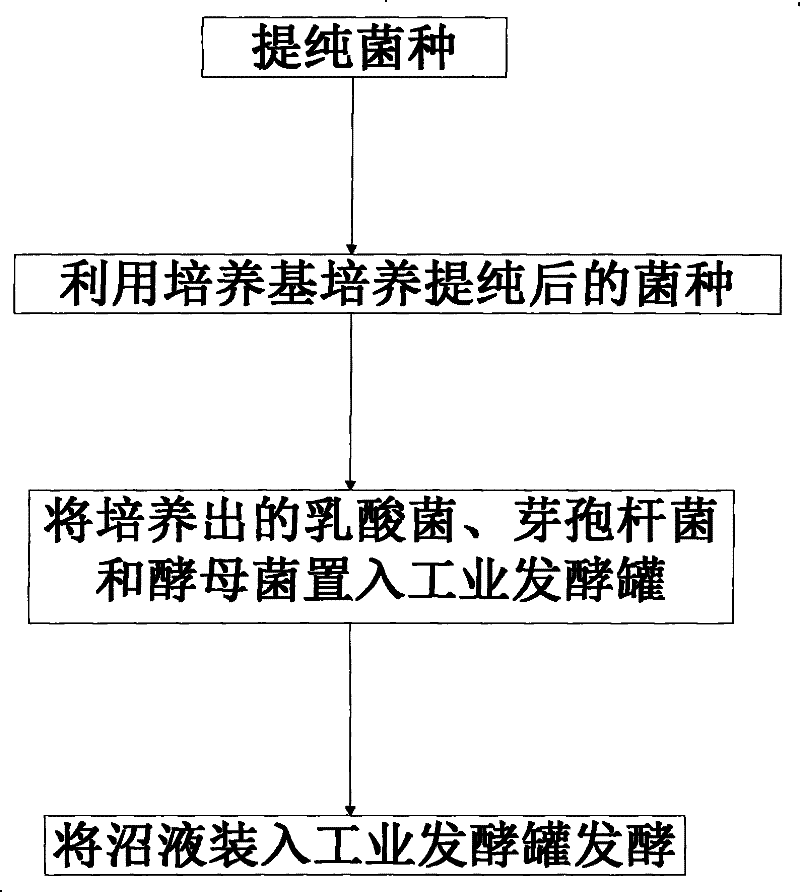

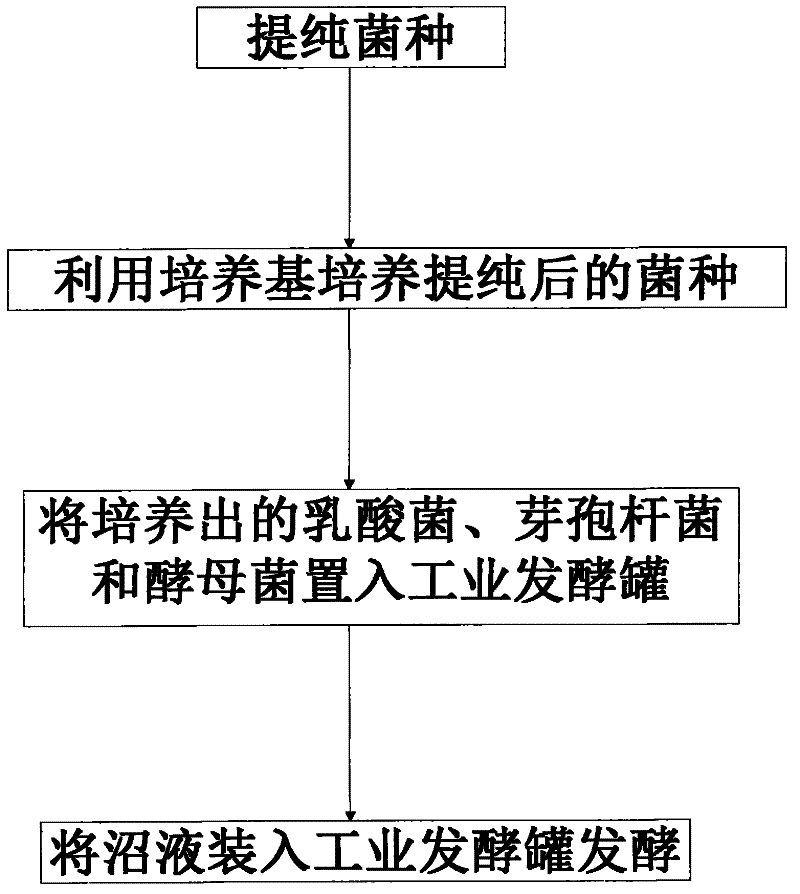

[0015] Embodiment two, such as figure 1 Shown, a kind of preparation method of biological liquid organic fertilizer, use biogas slurry and biogas residue produced by biogas digester as culture medium, adopt lactic acid bacteria, bacillus and yeast as beneficial microbial flora, utilize culture medium to cultivate beneficial microbial flora, The biogas slurry, biogas residue and beneficial microbial flora are put into an industrial fermenter for fermentation for 72-96 hours; the fermentation temperature is 60-70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com