Method for preparing ethyl nitrate by continuously nitrifying nitric acid steam

A technology of ethyl nitrate and nitric acid, which is applied in the preparation of nitrate esters, organic chemistry, etc., can solve the problems of not being used as military explosives, and achieve the effects of shortening the residence time, shortening the residence time, and reducing the chance of death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

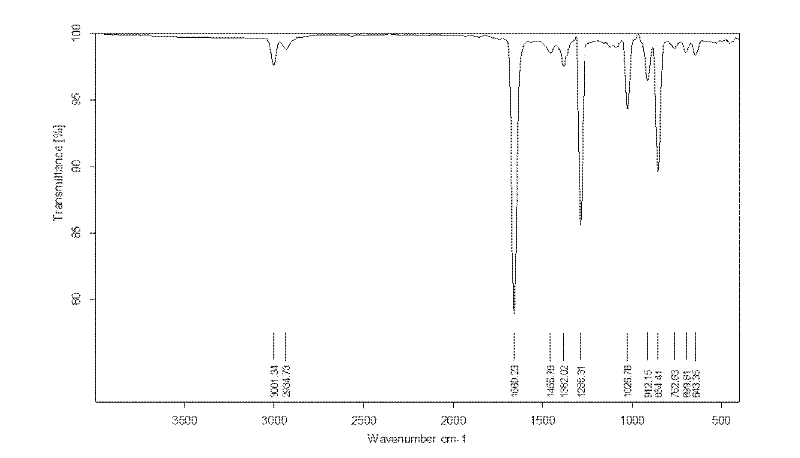

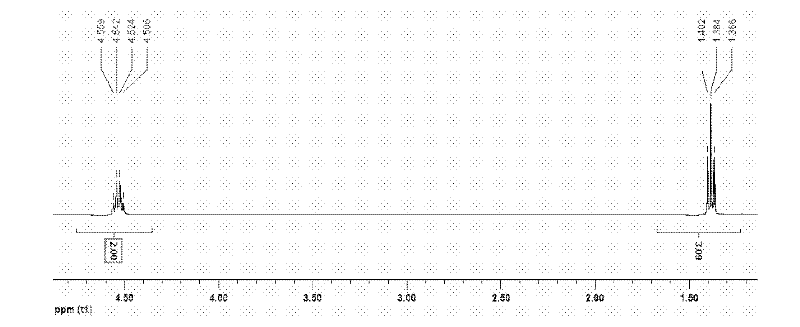

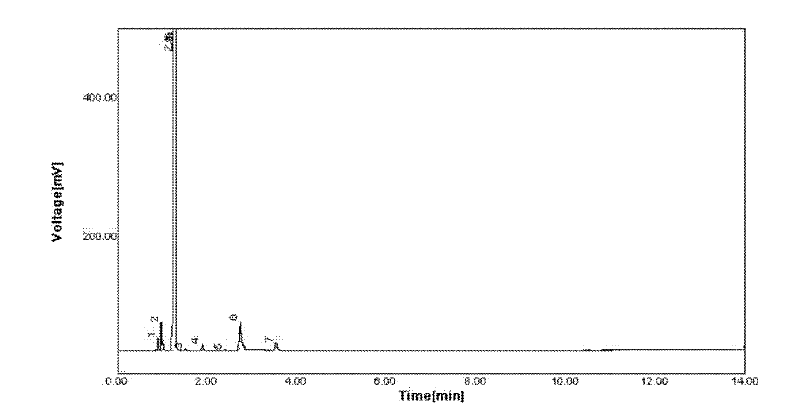

Image

Examples

Embodiment 1

[0041] Add protective agent and water to the 500ml reactor with oil bath heating device, the total addition is 160ml (about 185g) of nitrating agent, and the mass percentage content of three parts of nitrating agent is: HNO 3 75%, H 2 O is 15%, and protecting agent is 10%; Wherein, the mass percentage of protecting agent is urea 70%, dicyandiamide is 20%, and melamine is 10%;

[0042] First add 13g of urea, 3.7g of dicyandiamide, and 2g of melamine into the reactor system, add 28ml of water, make it completely dissolved, and then add 38g of 68% nitric acid, completely mix with this protective agent, and wait until the temperature of the system rises to 60 2mol absolute ethanol (92g) and 100g of 68% nitric acid were slowly added dropwise at °C, the temperature was raised to 90°C and reflux was started for 5 minutes. While refluxing, the product is initially distilled out. The upper layer of the crude product obtained at a distillation temperature of 90°C is unreacted ethanol, ...

Embodiment 2

[0046] Add protective agent and water to the 1000ml reactor with oil bath heating device, the total addition amount is 300ml (about 3500g) of nitrating agent, and the mass percentage content of three parts of nitrating agent is: HNO 3 75%, H 2 O is 15%, and protecting agent is 10%; Wherein, the mass percentage of protecting agent is urea 50%, and dicyandiamide is 50%;

[0047] In the reactor, first add protective agent and water, then add a little nitric acid participating in the reaction; slowly add 55mol absolute ethanol (2630g) dropwise when the temperature of the system rises to 60°C, heat up to 88°C and begin to reflux for 10 minutes, when the temperature rises to Stop reflux at 91°C. Control the drop rate of ethanol and nitric acid. At this time, the product is initially distilled while refluxing. The distillation temperature of the system is maintained at 90 ° C. The upper layer of the obtained crude product is unreacted ethanol, and the lower layer is crude ester and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com