Method for preparing and purifying hexaalkylguanidine chloride

A purification method and chloride technology, which is applied in the field of preparation and purification of phase transfer catalyst hexaalkylguanidine chloride, can solve the problems that liquid is difficult to polymerize at high temperature, restricts the application of hexaalkylguanidine salt, and affects the quality of polymers, etc. , to achieve the effect of easy transportation and storage, meeting the requirements of high temperature polymerization reaction, and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

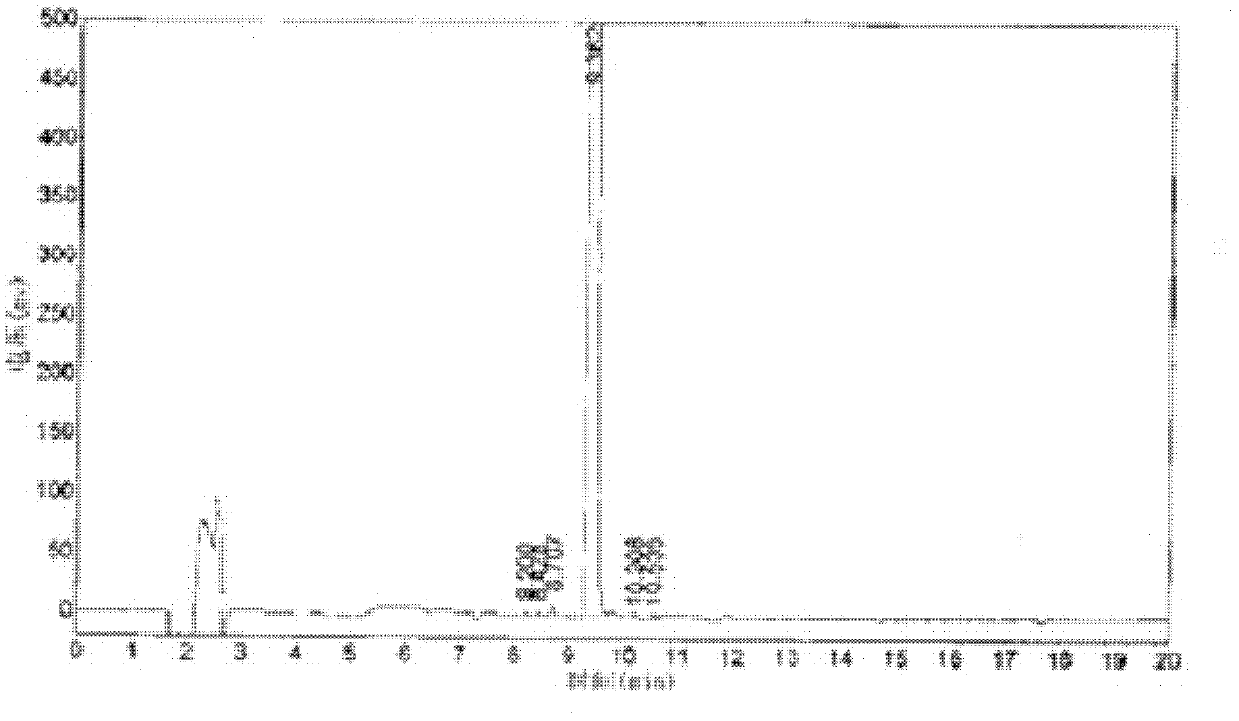

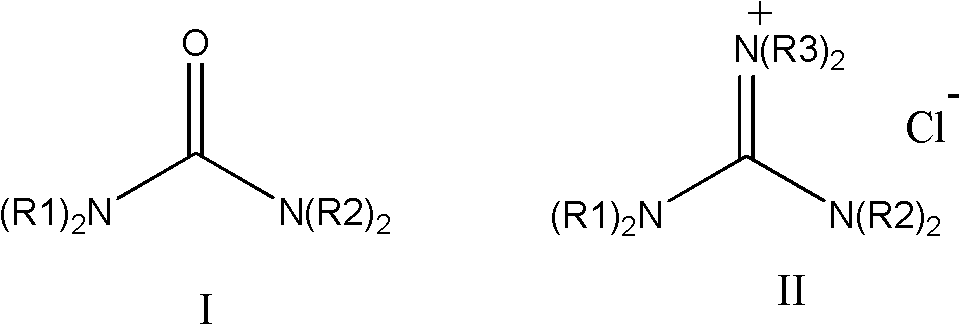

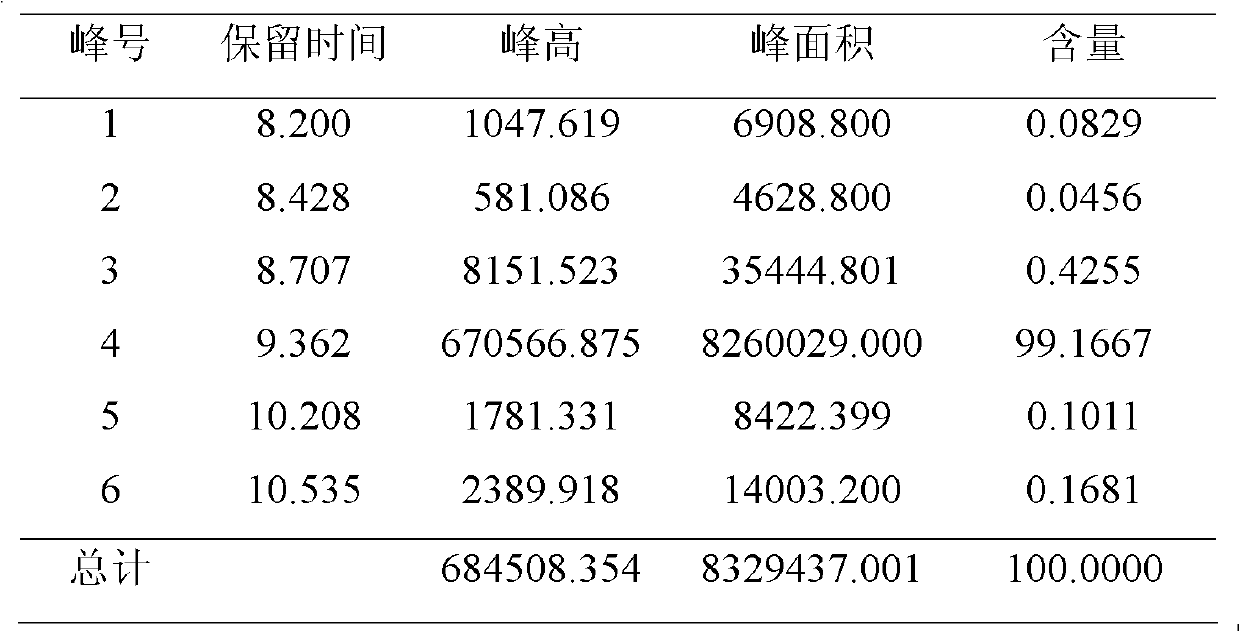

[0041] Under nitrogen protection, add tetraethylurea (43g, 0.25mol) in a 500ml four-necked flask equipped with stirring paddle, thermometer, condenser tube and nitrogen inlet tube, dry toluene (25ml), stir to make it dissolve, and Molecular sieves type HZSM-5 (1.25 g) were added. Then a solution of triphosgene (29.7 g, 0.10 mol) in toluene (125 ml) was added dropwise. After the dropwise addition, the temperature was raised to 60° C., and the stirring reaction was continued for 2 h. After the reaction was completed, the temperature was lowered to 0°C. Under nitrogen protection, diethylamine (43.8g, 0.6mol) was added dropwise, the reaction temperature was controlled at 20°C to 26°C, monitored by HPLC, after the reaction was finished, the pH value was adjusted to about 7.5 with 50wt% sodium hydroxide aqueous solution (100ml), Separation, water phase with CH 2 Cl 2 (50ml×5) extraction, combined CH 2 Cl 2 phase, dried over anhydrous magnesium sulfate, and the solvent was disti...

Embodiment 2

[0045] Under nitrogen protection, add tetramethylurea (75.4g, 0.65mol) to a 1L four-necked flask equipped with stirring paddle, thermometer, condenser tube and nitrogen inlet tube, dry toluene (110ml), stir to make it dissolve, And add HZSM-5 type molecular sieve (3.25g). Then a solution of triphosgene (80 g, 0.27 mol) in toluene (300 ml) was added dropwise. After the dropwise addition, the temperature was raised to 60° C., and the stirring reaction was continued for 2.7 h. After the reaction was completed, the temperature was lowered to 0°C. Under nitrogen protection, dropwise add dimethylamine (73g, 1.62mol), control reaction temperature at 20 ℃~26 ℃, HPLC monitors, after reaction finishes, adjust pH value to about 7.5 with 50wt% sodium hydroxide aqueous solution (280ml), divide Liquid, water phase with CH 2 Cl 2 (135ml×5) extraction, combined CH 2 Cl 2 phase, dried over anhydrous magnesium sulfate, and the solvent was distilled off under reduced pressure to obtain a ye...

Embodiment 3

[0047] Under nitrogen protection, add tetraethylurea (250g, 1.45mol) to a 5L four-necked flask equipped with a stirring paddle, a thermometer, a condenser tube and a nitrogen inlet tube, dry toluene (900ml), stir to dissolve it, add Zeolite H Beta (7.25 g). Then a solution of triphosgene (180 g, 0.61 mol) in toluene (750 ml) was added dropwise. After the dropwise addition, the temperature was raised to 60° C., and the stirring reaction was continued for 3 h. After the reaction was completed, the temperature was lowered to 0°C. Under nitrogen protection, dropwise add diethylamine (270g, 3.70mol), control reaction temperature at 20 ℃~26 ℃, HPLC monitors, after reaction finishes, adjust pH value to about 7.5 with 50wt% sodium hydroxide aqueous solution (660ml), divide Liquid, water phase with CH 2 Cl 2 (300ml×5) extraction, combined CH 2 Cl 2 phase, dried over anhydrous magnesium sulfate, and the solvent was distilled off under reduced pressure to obtain a yellow oil. It wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com