Halogen-free flame-retardant continuous fiber reinforced polypropylene composite material and preparation method thereof

A continuous fiber and composite material technology, which is applied in the field of halogen-free intumescent flame-retardant continuous glass fiber reinforced polypropylene composite material and its preparation, can solve the problem that the mechanical properties are not significantly improved, the impact toughness of the material is not substantially improved, and the It is difficult to meet the problems of high strength of composite materials, and achieve the effect of improving mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

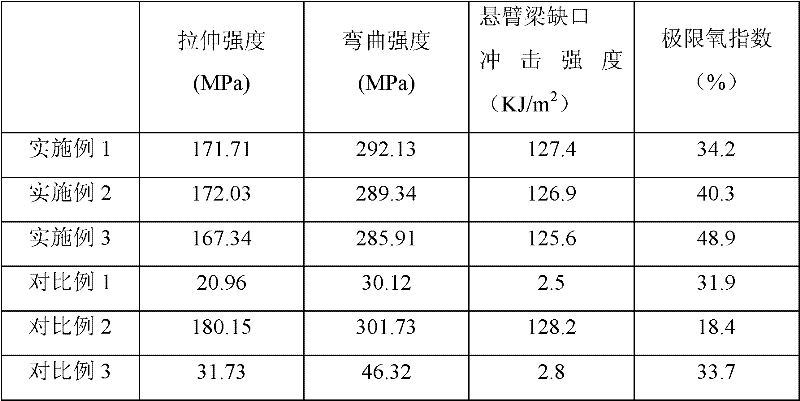

Embodiment 1

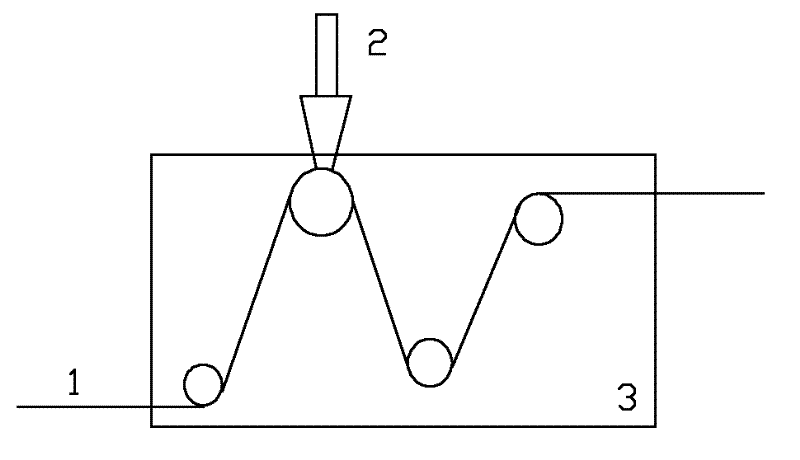

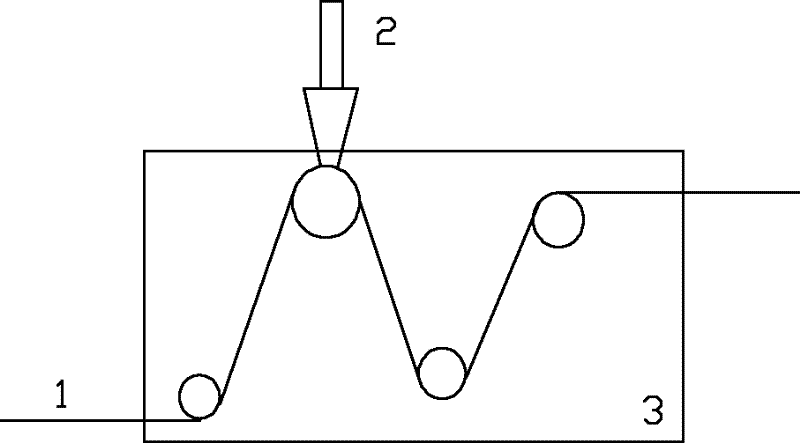

[0035] (a) Pre-introduce 100 parts of continuous glass fiber (1) into the composite mold (3)

[0036] (b) 80 parts of polypropylene (Shanghai Petrochemical, brand Y3700), 20 parts of polypropylene (Anqing Petrochemical Company, brand PPH-XD-075), 20 parts of ammonium polyphosphate (Qingdao Haihua Flame Retardant Material Co., Ltd.), melamine ( Jinan Taixing Fine Chemical Co., Ltd.) 10 parts, melamine borate (Jinan Taixing Fine Chemical Co., Ltd.) 5 parts, pentaerythritol (PER) (Puyang Yongan Chemical Co., Ltd.) 9 parts, antioxidant 1010 (Shanghai Ciba Fine Chemical Co., Ltd.) 0.4 part, antioxidant 168 (Shanghai Ciba Fine Chemical Co., Ltd.) 0.1 part, maleic anhydride grafted polypropylene 5 parts, the above raw materials were dried at 70 ° C for 12 h in a blast drying oven, and silane Coupling agent KH550 (Shanghai Jiachen Chemical Co., Ltd.) 0.5 parts, pass through the high-speed mixer together, mix and plasticize in the twin-screw extruder after mixing, the temperature of ea...

Embodiment 2

[0041] (a) 15 parts of continuous glass fibers (1) are pre-introduced into the composite mold (3)

[0042] (b) 80 parts of polypropylene (Shanghai Petrochemical Company, brand Y3700), 20 parts of polypropylene (Anqing Petrochemical Company, brand name PPH-XD-075), 30 parts of ammonium polyphosphate (Qingdao Haihua Flame Retardant Material Co., Ltd.), melamine (Jinan Taixing Fine Chemical Co., Ltd.) 14 parts, melamine borate (Jinan Taixing Fine Chemical Co., Ltd.) 8 parts, pentaerythritol (PER) (Puyang Yongan Chemical Co., Ltd.) 13 parts, antioxidant 1010 (Shanghai Automobile Co., Ltd.) Ciba Fine Chemical Co., Ltd.) 0.4 part, antioxidant 168 (Shanghai Ciba Fine Chemical Co., Ltd.) 0.1 part, maleic anhydride grafted polypropylene 5 parts, the above-mentioned raw materials were dried at 70° C. for 12 h in a blast drying oven, and mixed with Silane coupling agent KH550 (Shanghai Jiachen Chemical Co., Ltd.) 0.5 parts, together through the high-speed mixer, mixed and plasticized in ...

Embodiment 3

[0047] (a) 60 parts (1) of continuous glass fibers are preliminarily introduced into the composite mold (3).

[0048] (b) 80 parts of polypropylene (Shanghai Petrochemical, brand Y3700), 20 parts of polypropylene (Anqing Petrochemical Company, brand PPH-XD-075), 48 parts of ammonium polyphosphate (Qingdao Haihua Flame Retardant Material Co., Ltd.), melamine ( Jinan Taixing Fine Chemical Co., Ltd.) 20 parts, melamine borate (Jinan Taixing Fine Chemical Co., Ltd.) 12 parts, pentaerythritol (PER) (Puyang Yongan Chemical Co., Ltd.) 20 parts, antioxidant 1010 (Shanghai Ciba Fine Chemical Co., Ltd.) 0.4 part, antioxidant 168 (Shanghai Ciba Fine Chemical Co., Ltd.) 0.1 part, maleic anhydride grafted polypropylene 5 parts, the above raw materials were dried at 70 ° C for 12 h in a blast drying oven, and silane Coupling agent KH550 (Shanghai Jiachen Chemical Co., Ltd.) 0.5 parts, pass through the high-speed mixer together, mix and plasticize in the twin-screw extruder after mixing, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com