Antifreezing snow melting agent and preparation method thereof

The technology of a snow-melting agent and a retarding agent is applied to the composition field of anti-freezing snow-melting agents, which can solve the problems of high price and the like, and achieve the effects of lowering the freezing point, prolonging the deicing action time, and improving the crop yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of antifreeze type deicing agent

[0034] 1. Preparation of organic water-absorbing agent: under the condition of 20° C., prepare 10 g of mass concentration of 1% chitosan hydrochloride solution, pH value is 5.7, and the mass concentration of 10 g is 1% of chitosan hydrochloride solution Mix with 50g of soluble starch, and stir evenly to obtain 60g of organic water-absorbing agent.

[0035] 2. Preparation of freezing point depressant: Mix 80 g of ethanol with 70 g of glycerin and 30 g of ethylene glycol and stir evenly to obtain 180 g of freezing point depressant.

[0036] 3. Preparation of freezing retarder: crush 20 g of diammonium phosphate, 20 g of urea, 10 g of ammonium sulfate, 10 g of ammonium nitrate, 3 g of sodium acetate, 1 g of zinc acetate, and 1 g of ferric nitrate, add 44 g of water and stir evenly to obtain 109 g of freezing retarder.

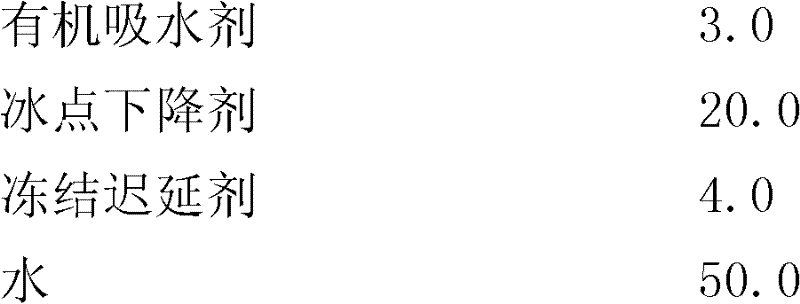

[0037] 4. After mixing 25g of the above-mentioned organic water-absorbing agent, 150g of freezing point...

Embodiment 2

[0075] (1) Preparation of antifreeze type deicing agent

[0076] 1. Preparation of organic water-absorbing agent: under the condition of 20° C., prepare 10 g of mass concentration of 1% chitosan hydrochloride solution, the pH value is 5.5, and the mass concentration of 10 g is 1% of chitosan hydrochloride solution Mix with 20g of soluble starch, and stir evenly to obtain 30g of organic water-absorbing agent.

[0077] 2. Preparation of freezing point depressant: Mix 20 g of ethanol with 40 g of glycerin and 15 g of ethylene glycol and stir evenly to obtain 75 g of freezing point depressant.

[0078] 3. Preparation of freezing retarder: crush 40 g of diammonium phosphate, 40 g of urea, 10 g of ammonium sulfate, 10 g of ammonium nitrate, 2 g of sodium acetate, 0.8 g of zinc acetate, and 1 g of ferric nitrate, add 64 g of water and stir evenly to obtain 167.8 g of freezing retarder.

[0079] 4. After mixing 10g of the above-mentioned organic water-absorbing agent, 75g of freezing...

Embodiment 3

[0109] (1) Preparation of antifreeze type deicing agent

[0110] 1. Preparation of organic water-absorbing agent: under the condition of 20° C., prepare 30 g mass concentration of 1% chitosan hydrochloride solution, pH value is 5.6, and 20 g mass concentration of 1% chitosan hydrochloride solution Mix with 30g of soluble starch, and stir evenly to obtain 50g of organic water-absorbing agent.

[0111] 2. Preparation of freezing point depressant: Mix 30 g of ethanol with 50 g of glycerin and 20 g of ethylene glycol and stir evenly to obtain 100 g of freezing point depressant.

[0112] 3. Preparation of freezing retarder: crush 20 g of diammonium phosphate, 20 g of urea, 5 g of ammonium sulfate, 5 g of ammonium nitrate, 2 g of sodium acetate, 2 g of zinc acetate, and 1 g of ferric nitrate, add 55 g of water and stir evenly to obtain 110 g of freezing retarder.

[0113] 4. Mix 15g of the above-mentioned organic water-absorbing agent, 100g of freezing point depressant, and 20g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com