Production method of sucrose ester and use thereof in preparation of special antioxidant for oil

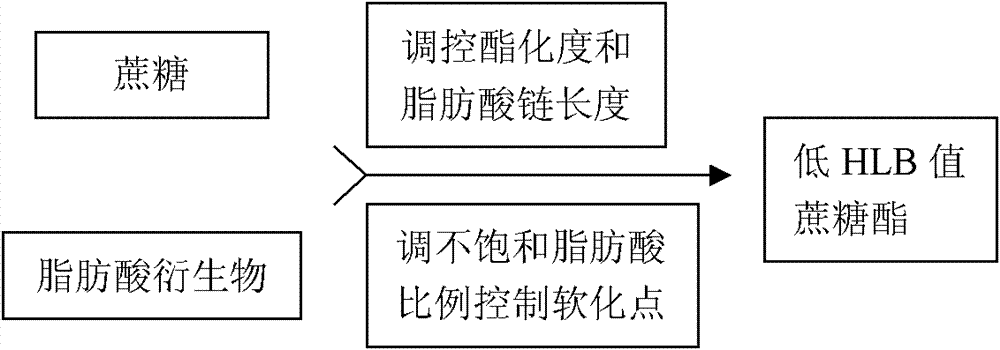

A technology of antioxidants and production methods, applied in the fields of application, fatty acid esterification, edible oil/fat, etc., to achieve the effects of improving the use effect, shortening the process flow, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

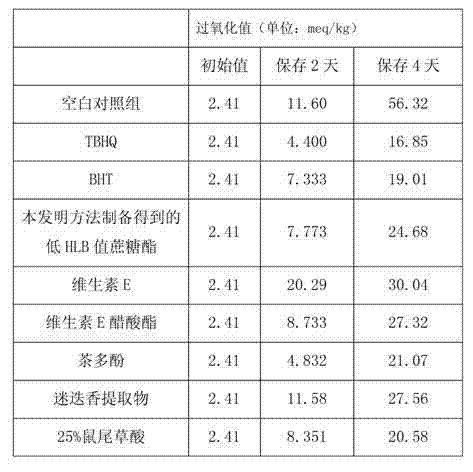

Examples

Embodiment 1

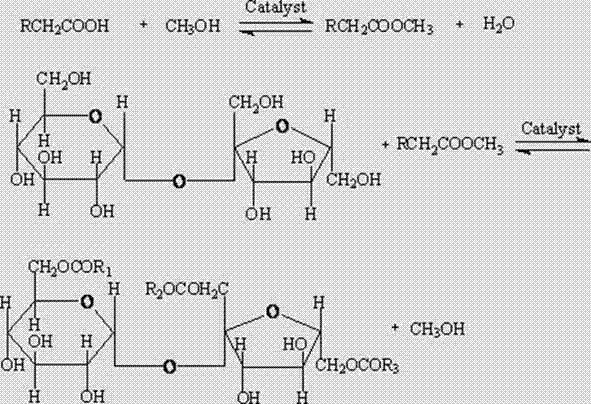

[0033] Embodiment 1: a kind of production method of sucrose ester.

[0034] Synthesis of unsaturated fatty acid methyl esters - fatty acid methyl esters of camellia oleifera seed oil: 800 ml of tea seed oil, 1000 ml of methanol and 15 ml of concentrated sulfuric acid were added to a 3000 ml round-bottomed three-necked flask, and the temperature was raised to reflux under stirring. When there are drops of methanol dripping from the lower port of the condenser, the reaction is timed. Backflow begins when the droplet fills the lower end of the trap. The temperature in the reflux process is controlled at 80-90° C., and the reaction time is 6-8 hours. After the timing is over, open the water diversion port of the water separator to collect excess methanol until the collection is complete. Wash the product in the flask with water until the pH value is 6.5-7.5 (3 times with 500 ml of water each time), to obtain a colorless or very light yellow product, and remove the water at 120°C...

Embodiment 2

[0036] Embodiment 2: a kind of production method of sucrose ester.

[0037] The preparation process of Camellia oleifera seed oil fatty acid methyl ester is identical with embodiment 1.

[0038] In a 3000 ml round bottom flask, add 200 ml of aqueous solution containing 10 g of KOH, 50 g of stearic acid, heat up to 70°C under stirring, add 350 g of sucrose, 35 g of potassium carbonate, 250 g of methyl palmitate and 500 g of gram camellia seed oil fatty acid methyl ester, after mixing, stir at 80 degrees centigrade for 30 minutes. Turn on the vacuum to extract water, heat at the same time, increase the vacuum as much as possible without the temperature dropping, until the temperature rises to 125°C and the pressure -0.098MPa enters the reaction. Reaction time 6 hours. After the reaction is over, stop heating, and after the product is cooled to 90-95°C, add 1500 ml of absolute ethanol with a funnel under stirring, reflux at a temperature of 78.5-90°C for 20 minutes, and then ad...

Embodiment 3

[0039] Embodiment 3: a kind of production method of sucrose ester.

[0040] The preparation process of Camellia oleifera seed oil fatty acid methyl ester is identical with embodiment 1.

[0041] In a 3000 ml round bottom flask, add 200 ml of aqueous solution containing 6 g of KOH, 30 g of stearic acid, heat up to 70°C under stirring, add 350 g of sucrose, 35 g of potassium carbonate, 450 g of methyl palmitate and 300 g of gram camellia seed oil fatty acid methyl ester, after mixing, stir at 80 degrees centigrade for 30 minutes. Turn on the vacuum to extract water, heat at the same time, and increase the vacuum as much as possible without the temperature dropping, until the temperature rises to 114°C and the pressure is -0.098MPa to enter the reaction. Reaction time 11 hours. After the reaction is over, stop heating, and after the product is cooled to 90-95°C, add 1500 ml of absolute ethanol with a funnel under stirring, reflux at a temperature of 78.5-90°C for 20 minutes, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com