Production method of high-purity germanium dioxide

A germanium dioxide and production method technology, applied in the directions of germanium dioxide, process efficiency improvement, etc., can solve the problems of limited output, equipment corrosion, high production labor intensity, etc., achieve good effect, improve freezing efficiency, and reduce work intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

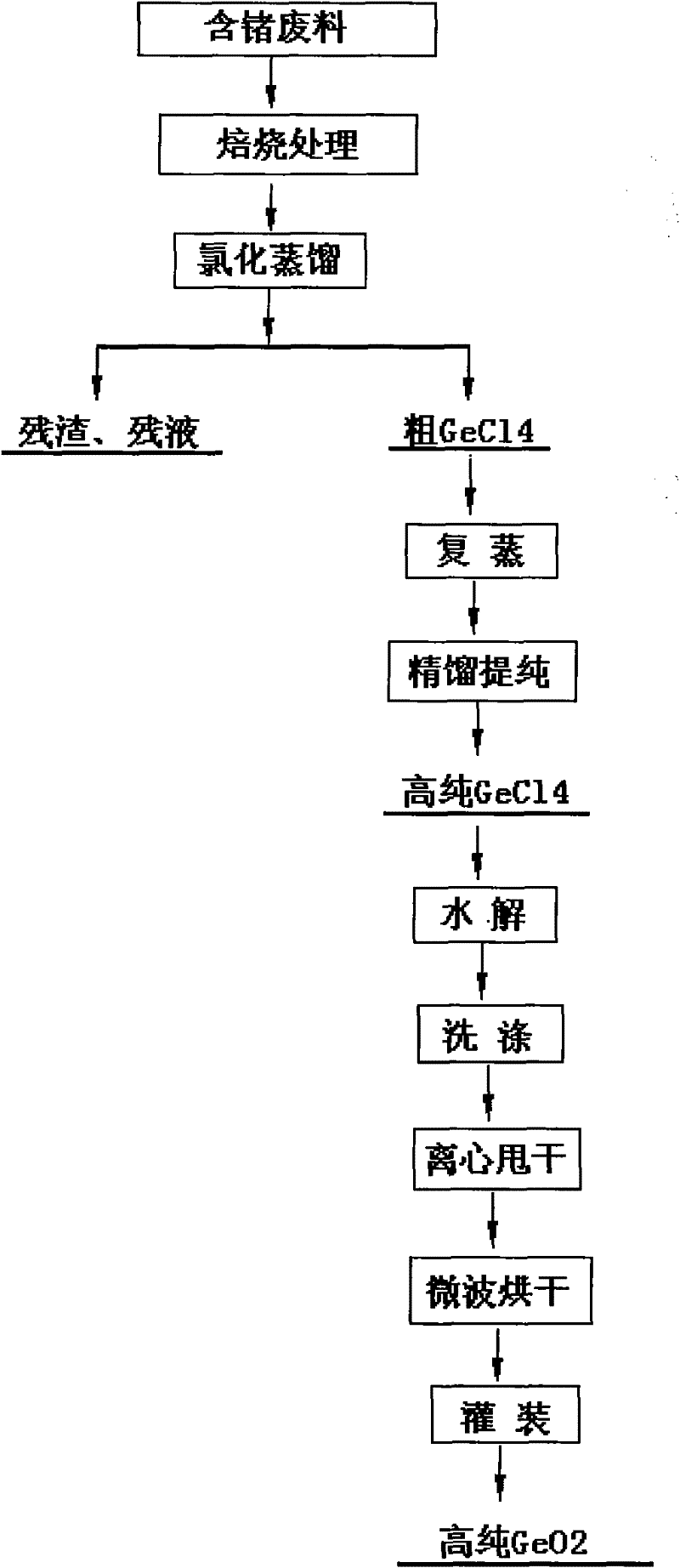

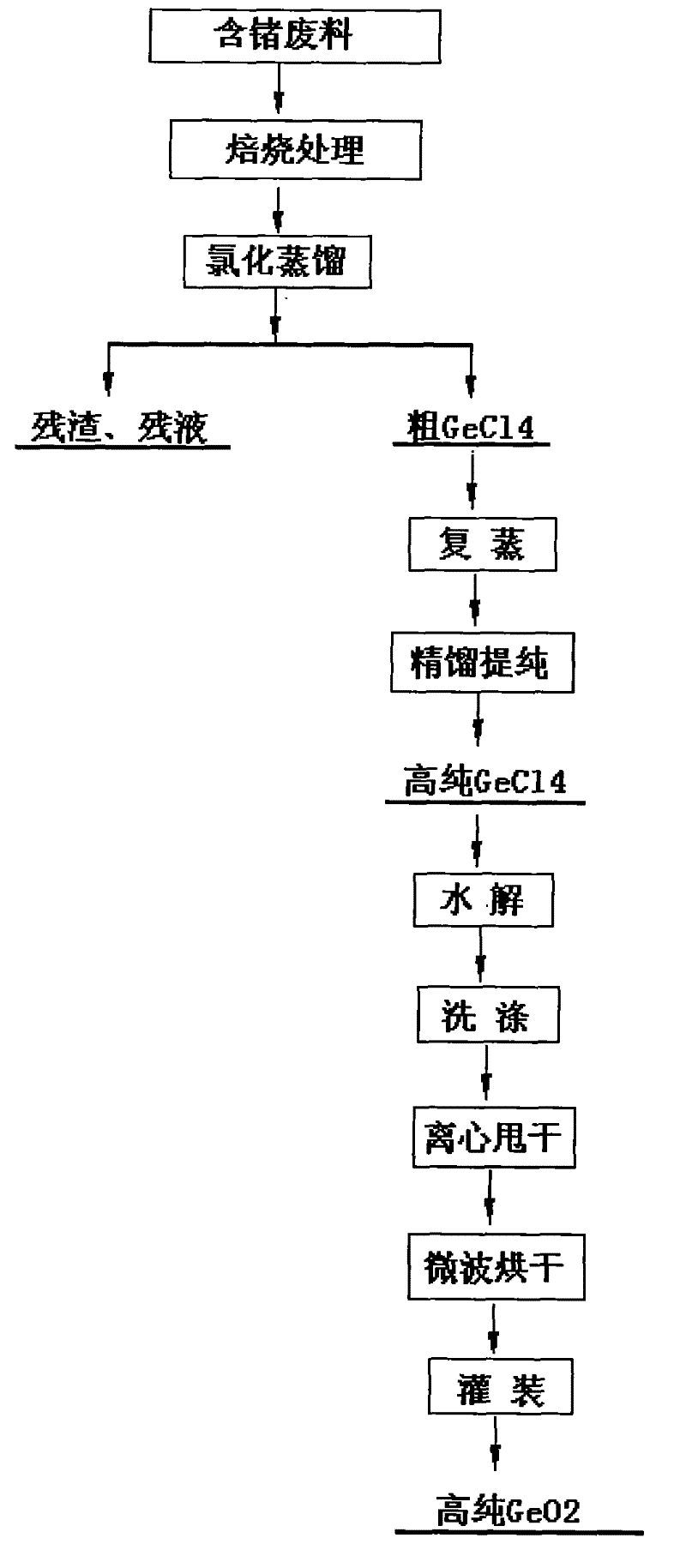

[0027] (1) Roasting treatment of germanium-containing waste. After sampling and testing the germanium-containing waste, determine the quality of soda ash added according to the test results of the germanium content, put the germanium crystal waste and soda ash into a ball mill according to 1:1.5 (mass ratio) for ball milling, and when the germanium crystal waste and soda ash are fully mixed Put the mixture of the two into a roasting furnace for high-temperature roasting, control the roasting temperature at 550°C and the roasting time for 6 hours, so that the metal germanium is transformed into acid-soluble germanate, which is convenient for the next step of processing;

[0028] (2) Chlorination distillation of germanium-containing raw materials. Add the calcined germanium-containing raw material and industrial hydrochloric acid into the distillation kettle at a ratio of 1:4, and add concentrated sulfuric acid and ferric chloride with a concentration of 93% to increase the conc...

Embodiment 2

[0039] (1) Roasting treatment of germanium-containing waste. After the germanium-containing waste is sampled and detected, the quality of soda ash added is determined according to the detection result of the germanium content, and the germanium crystal waste and soda ash are put into a ball mill for ball milling according to a mass ratio of about 1:2. When the germanium crystal waste and soda ash are fully mixed, the The mixture of the two is put into a roasting furnace for high-temperature roasting, and the roasting temperature is controlled at 600°C and the roasting time is 5 hours, so that the metal germanium is transformed into acid-soluble germanate, which is convenient for the next step of processing;

[0040] (2) Chlorination distillation of germanium-containing raw materials. Add the roasted germanium-containing raw material and industrial hydrochloric acid into the distillation kettle at a solid-to-liquid ratio of 1:8, and add concentrated sulfuric acid and ferric chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com